Preparation method for coating oxide powder with amorphous phosphate thin layer by soaking in mixed acid liquor

A technology of oxide powder and phosphate, which is applied in the direction of phosphate, chemical instruments and methods, nickel compounds, etc., to achieve the effects of easy operation, large-scale application, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

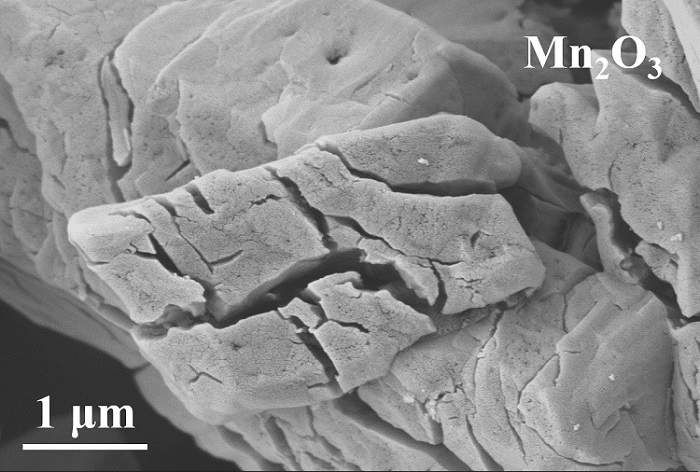

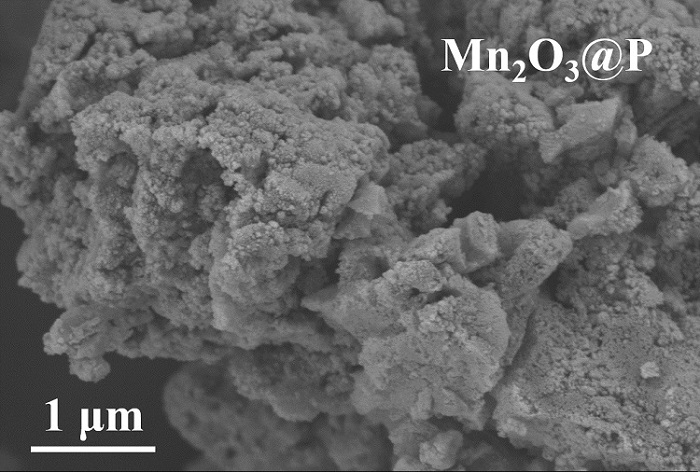

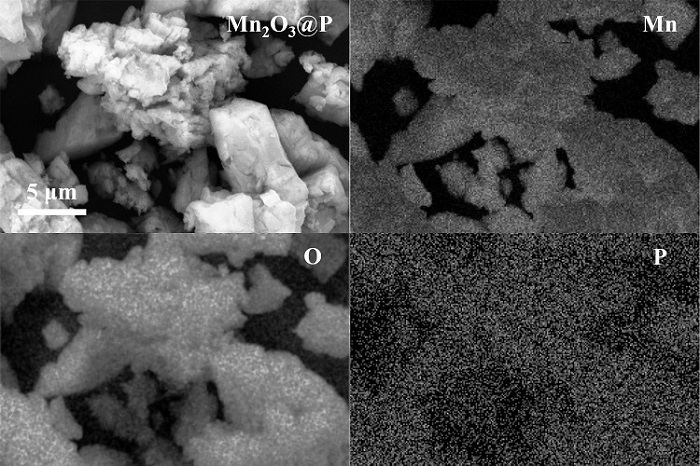

Embodiment 1

[0032] Measure 17.1 μL concentrated phosphoric acid (98%wt), weigh 0.3 g SA, disperse in 50 mL ethanol, and mix with 5 g manganese trioxide (Mn 2 o 3 ) powders were mixed, and stirred continuously for 1.5 h at 25 °C. After the reaction, washed twice with deionized water and once with ethanol, the powder was collected and dried in a vacuum oven at 60 °C for 12 h to obtain about 3- 15 nm thick amorphous phosphate-coated Mn 2 o 3 Powder.

Embodiment 2

[0034] Measure 20.3 μL of concentrated phosphoric acid (98%wt), weigh 1.0 g of modified starch and disperse in 70 mL of ethylene glycol, and then mix with 5 g of ternary material LiNi 0.8 co 0.15 Al 0.05 o2 (NCA) mixed, stirred continuously at 30 °C for 4 h, after the reaction, washed with deionized water and ethanol three times each, and dried in a vacuum oven at 40 °C for 12 h to obtain a 3-15 nm thick Amorphous phosphate-coated NCA powder.

Embodiment 3

[0036] Measure 30.5 μL concentrated phosphoric acid (98%wt), weigh 0.5 g SA and disperse in 100 mL ethanol, and mix with 5 g manganese trioxide (Mn 2 o 3 ) powders were mixed and stirred continuously for 1.5 h at 25 °C. After the reaction was over, the powder was washed twice with deionized water and once with ethanol, and the powder was collected and dried in a vacuum oven at 60 °C for 12 h to obtain about 7- 20 nm thick amorphous phosphate-coated Mn 2 o 3 Powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com