C-axis pore-forming graphite as well as preparation method and application thereof

A graphite and hole-making technology, applied in the direction of graphite, structural parts, electrical components, etc., can solve the problem that graphene cannot be kept well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

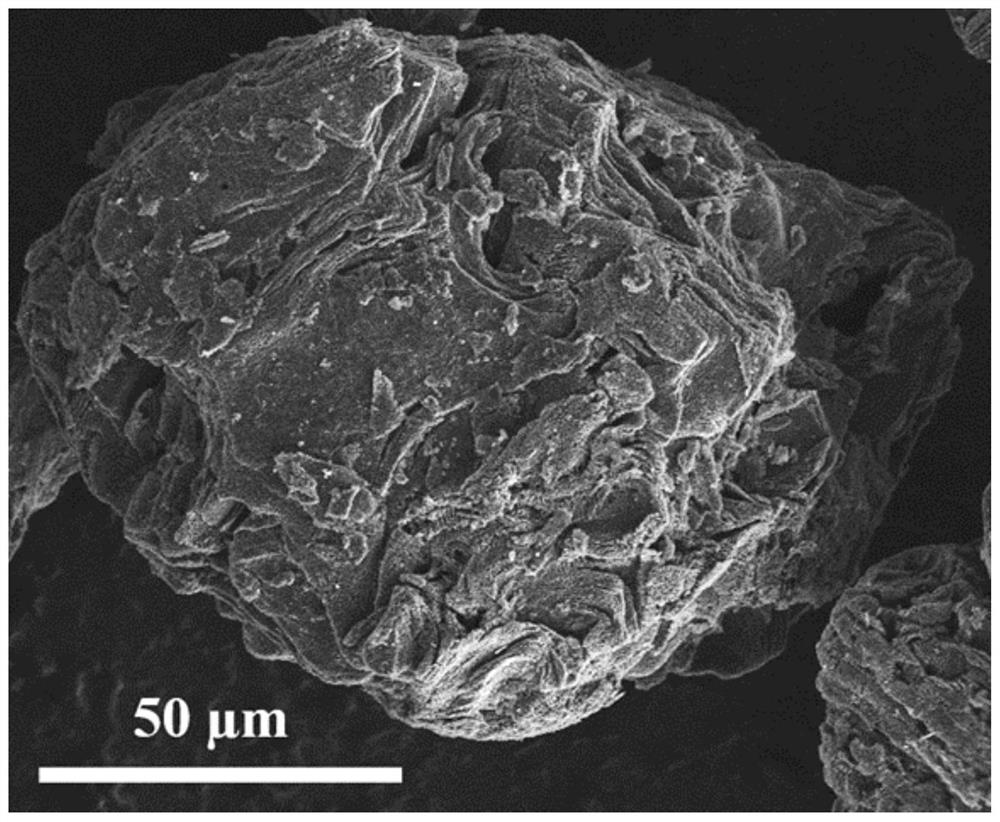

[0026] Preparation of graphite embedded with compound particles

[0027] Fix the graphite block or graphite powder compact on the molybdenum rod collector as the working electrode, the graphite rod as the counter electrode, the Ag / AgCl electrode as the reference electrode, and the chloride molten salt at 400°C to 1000°C as the electrolyte. An electrode potential of -0.9-2.0V (vs.Ag / AgCl) is applied to the electrode for cathodic polarization, and the polarization time is 0.5-4h. The cathodic polarization product is taken out, cooled and washed with water to obtain an embedded graphite-based composite material embedded with 3-30 wt% compound particles, that is, graphite embedded with compound particles.

Embodiment 1

[0029] Graphite embedded with 6 wt% LiCl particles was heated in air atmosphere at 350 °C and 450 °C for 2 h, respectively. Cool to room temperature, take out the sample, wash with water or dilute hydrochloric acid, and dry to obtain the porosity of the C-axis pore-forming graphite is about 5% and 60%, respectively.

Embodiment 2

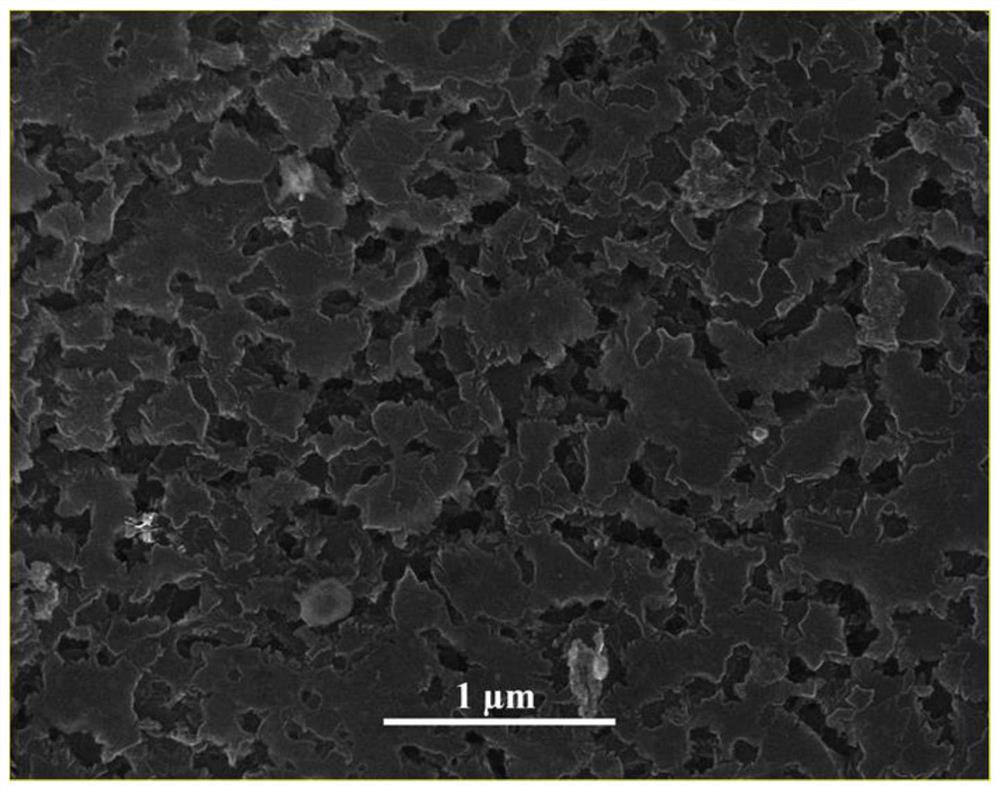

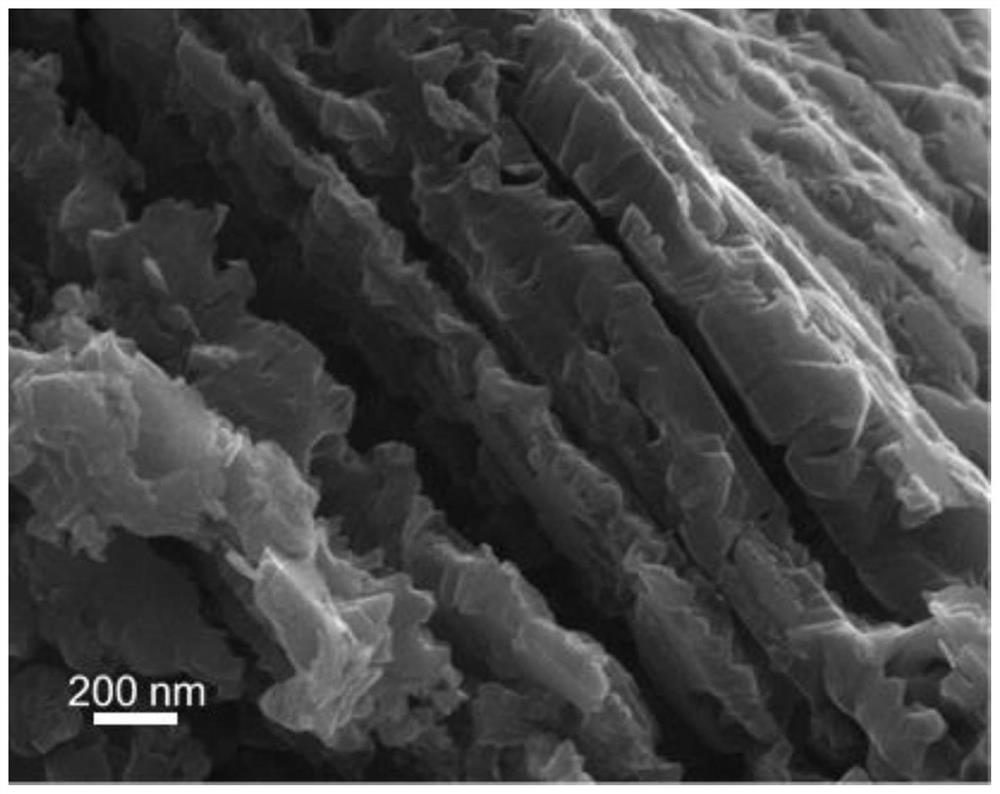

[0031] Graphite embedded with 6 wt% LiCl particles was heated at 400 °C in an air atmosphere for 10 h. Cool to room temperature, take out the sample, wash with water or dilute hydrochloric acid, and dry to obtain a C-axis pore-forming graphite with a porosity of about 70%. It shows that the pore size on the C-axis pore-forming graphite plane layer prepared under this condition is between 50-150nm, and the plane diffusion range of the basic graphite layer structure unit is between 10-200nm. The thickness of the basic graphite unit in the C-axis direction is greater than 20 nm.

[0032] Mix the planar pore-forming graphite with acetylene black and polyvinylidene fluoride in a mass ratio of 80:10:10, adjust it into a slurry, and evenly coat it on copper foil (99.99%) to make a working electrode. The sheet is the counter electrode, the polypropylene microporous membrane is the separator, 1M LiPF6 (EC-DEC=1:1vol%+10%FEC) was used as the electrolyte, and the button battery was asse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com