Treatment method of high-concentration high-salinity wastewater in nitrochlorobenzene meta-position oil separation

A nitrochlorobenzene meta-oil, high-concentration technology, applied in the direction of neutralization water/sewage treatment, water/sewage treatment, water treatment parameter control, etc. The three wastes of the chlorobenzene-meta-position oil separation technology have achieved the effect of saving processing time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

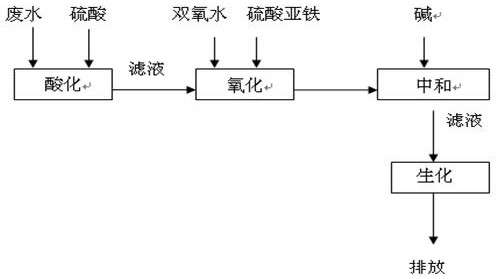

Image

Examples

Embodiment 1

[0022] ①Acidification process: Collect 1000mL of etherified wastewater with a COD of 75000 mg / L and a chroma of 4100, add 20% sulfuric acid dropwise for acidification, adjust the pH to 3~4, the color of the solution turns from brownish red to khaki yellow, and precipitates Yellow crystal, with vacuum filtration, the filtrate was taken for analysis, the COD was reduced to 45000 mg / L, and the filter residue was mainly o-nitrophenol (93.03%) and a small amount of nitroanisole (5.52%).

[0023] ② Oxidation process: take 30ml of acidified water sample and dilute it 10 times, then add it to a 500ml four-necked flask, raise the temperature to 80-90°C while stirring, maintain the temperature, and drop the measured 10 % ferrous sulfate solution and 25% hydrogen peroxide. After the addition, the reaction was cooled for 30 minutes. When it reached 50°C, start adding alkali to adjust the pH to 7~8. There was precipitation in the bottle. It is iron salt, the COD of the oxidized effluent i...

Embodiment 2

[0026] ① Acidification process: Collect 1000mL of etherification wastewater with a COD of 76000 mg / L and a chroma of 4200, add 20% phosphoric acid dropwise for acidification, adjust the pH to 3~4, the color of the solution turns from brownish red to earthy yellow, and precipitates Yellow crystal, with vacuum filtration, the filtrate was taken for analysis, the COD was reduced to 40000 mg / L, and the filter residue was mainly o-nitrophenol (94.25%) and a small amount of nitroanisole (3.89%).

[0027] ②Oxidation process: take 30ml of acidified water sample and dilute it 10 times, then add it to a 500ml four-necked flask, raise the temperature to 80-90°C while stirring, maintain the temperature, and drop the measured 12 % ferrous sulfate solution and 29% hydrogen peroxide. After adding, react for 20 minutes to cool down. When it reaches 50°C, start adding alkali to adjust the pH to 7~8. There is precipitation in the bottle. It is iron salt, the COD of the oxidized water is 630 mg...

Embodiment 3

[0030] ① Acidification process: Collect 1000mL of etherified wastewater with a COD of 59000 mg / L and a chroma of 3000, add 25% sulfuric acid dropwise for acidification, adjust the pH to 3~4, the color of the solution turns from brownish red to khaki yellow, and precipitates Yellow crystal, with vacuum filtration, the filtrate was taken for analysis, the COD was reduced to 20000 mg / L, and the filter residue was mainly o-nitrophenol (93.25%) and a small amount of nitroanisole (6.19%).

[0031] ② Oxidation process: Take 30ml of acidified water sample and dilute it 15 times, then add it into a 500ml four-necked flask, heat up to 80-90°C while stirring, and keep the temperature, dropwise add the measured 12 % ferrous sulfate solution and 20% hydrogen peroxide. After adding, react for 20 minutes to cool down. When it reaches 50°C, start adding alkali to adjust the pH to 7~8. There is precipitation in the bottle. It is an iron salt, the COD of the oxidized water is 350 mg / L, the chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com