Quick QCM humidity sensor, application thereof and preparation method of humidity sensor

A humidity sensor, a fast technology, applied in the direction of instruments, scientific instruments, coatings, etc., can solve the problems of restricting applications and affecting the diffusion of water molecules, etc., to improve repeatability and hysteresis, high Q value, and improve process controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

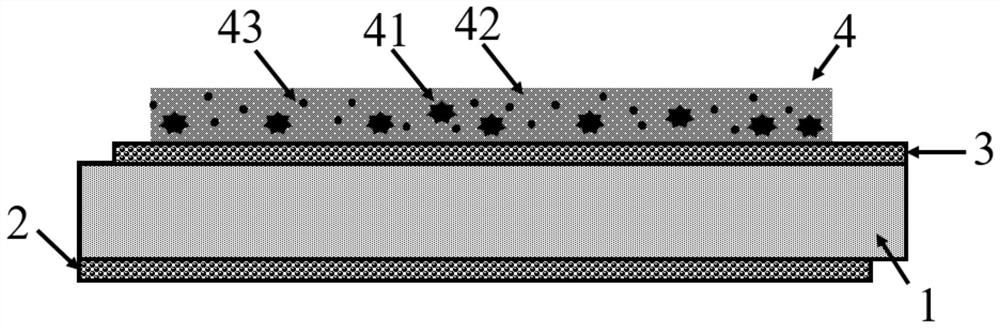

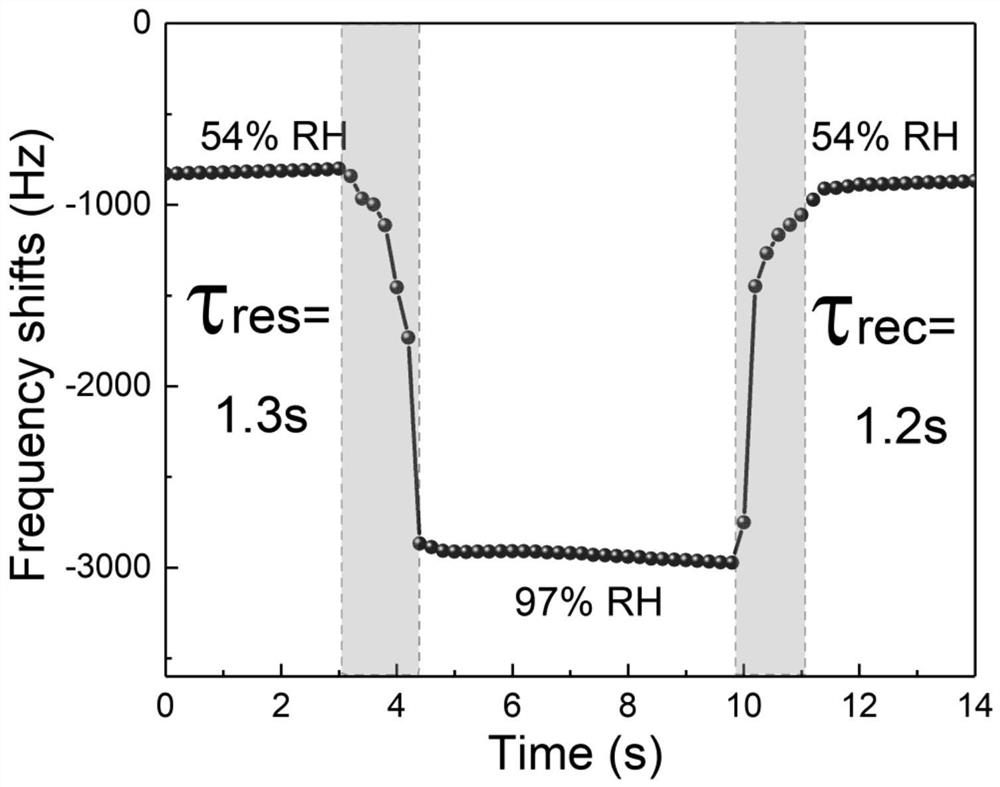

[0036] A preparation method for a fast QCM humidity sensor, comprising the following steps:

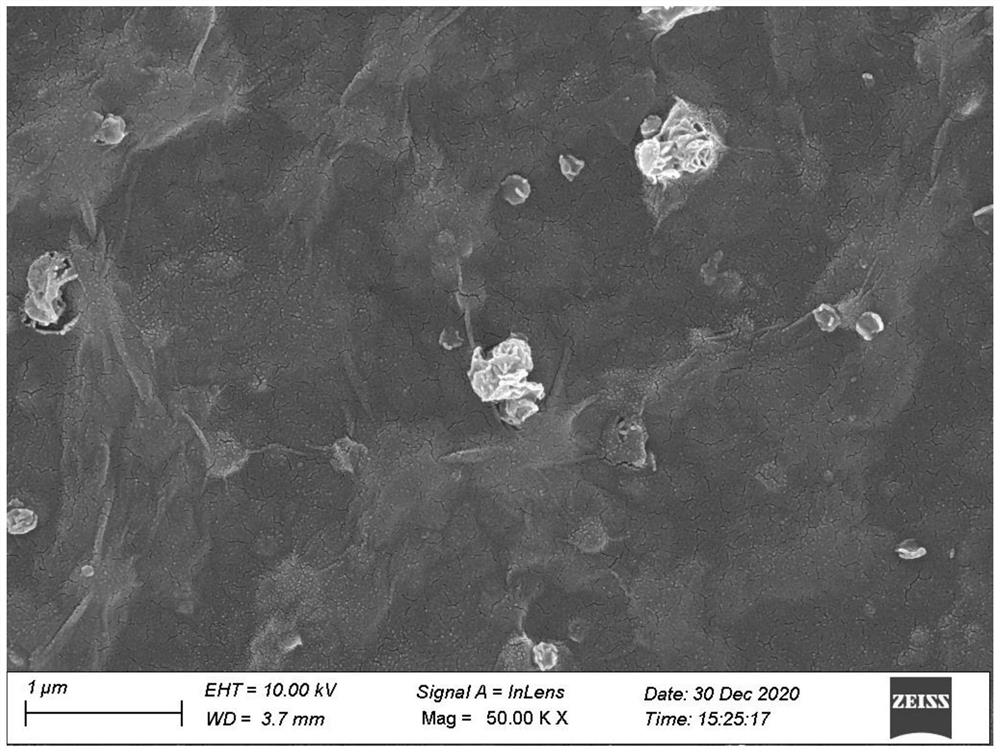

[0037] Step 1: Dissolve 2.46g of ammonium molybdate and 4.55g of thiourea in 75ml of deionized water, and stir ultrasonically for 40 minutes; a uniform solution is obtained, and then the obtained solution is transferred to a high-temperature reactor, and passed through hydrothermal heating at 180°C reaction method for 12 hours, then naturally cooled to room temperature; washed with deionized water and / or absolute ethanol for 3 to 5 times, and finally centrifuged at 1500rpm for 10 minutes, and then collected molybdenum disulfide in a vacuum at 60°C drying in a drying oven to obtain molybdenum disulfide nanoflower powder for subsequent use;

[0038] Step 2: 1 mg of molybdenum disulfide powder, 1 mg of graphene oxide (diameter 1000 nm), fullererol powder 1 mg (particle size 20 nm) are ultrasonically dispersed in a mixed solution of 1 ml deionized water and ethanol to obtain a molybdenum ...

Embodiment 2

[0050] A preparation method for a fast QCM humidity sensor, comprising the following steps:

[0051] Step 1: Dissolve 2g of ammonium molybdate and 4g of thiourea in 70ml of deionized water, and stir ultrasonically for 30 minutes; obtain a uniform solution, then transfer the obtained solution to a high-temperature reactor, and react by hydrothermal method at 150°C After 12 hours, cool naturally to room temperature; wash with deionized water and / or absolute ethanol for 3 to 5 times, and finally centrifuge at 1800rpm for 15 minutes, then place the collected molybdenum disulfide in a vacuum oven at 60°C Drying in middle, finally get molybdenum disulfide nano flower powder for standby;

[0052] Step 2: molybdenum disulfide powder 3mg, graphene oxide 3mg (diameter 800nm), fullerenol powder 3mg (particle diameter 15nm) are ultrasonically dispersed in the mixed solution of 2ml deionized water and ethanol to obtain molybdenum disulfide solution (1.5 mg / ml), graphene oxide solution (1....

Embodiment 3

[0057] A preparation method for a fast QCM humidity sensor, comprising the following steps:

[0058] Step 1: Dissolve 3g ammonium molybdate and 6g thiourea in 90ml deionized water, and stir ultrasonically for 50 minutes; obtain a uniform solution, then transfer the obtained solution to a high-temperature reactor, and react by hydrothermal method at 190°C After 10 hours, cool naturally to room temperature; wash with deionized water and / or absolute ethanol for 3 to 5 times, and finally centrifuge at 2000rpm for 15 minutes, then place the collected molybdenum disulfide in a vacuum oven at 60°C Drying in middle, finally get molybdenum disulfide nano flower powder for standby;

[0059] Step 2: molybdenum disulfide powder 5mg, graphene oxide 5mg (sheet diameter 500nm), fullererol powder 5mg (particle diameter 15nm) ultrasonic dispersion in the mixed solution of 2.5ml deionized water and ethanol obtains molybdenum disulfide solution ( 2mg / ml), graphene oxide solution (2mg / ml) and fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com