Electroluminescent compound and preparation method and application thereof

A technology of luminescence and compounds, which is applied in the field of electroluminescence compounds and their preparation, can solve the problems of low transmission efficiency and poor stability, and achieve the effects of improving luminescence performance, high stability, and reducing driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

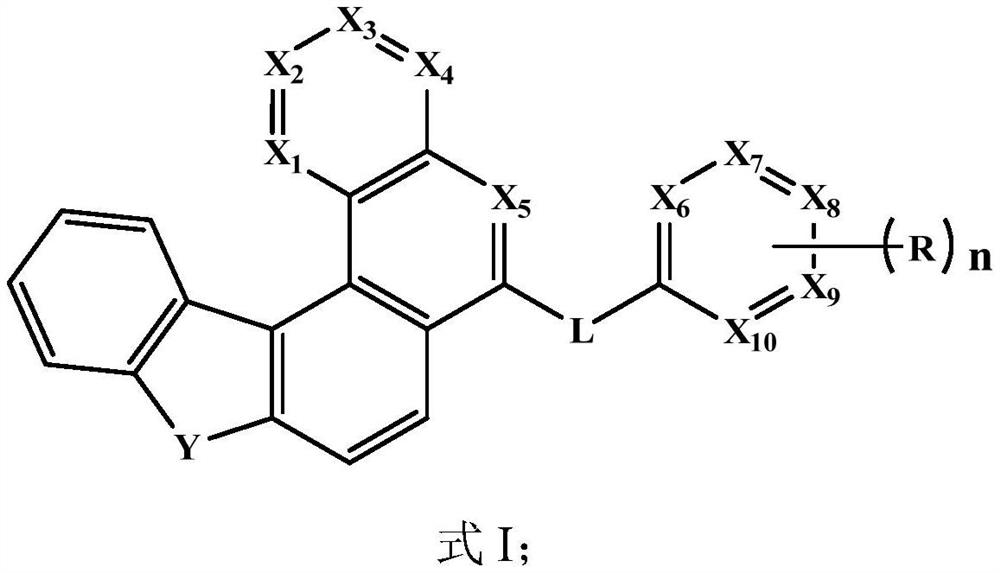

Method used

Image

Examples

Embodiment 1

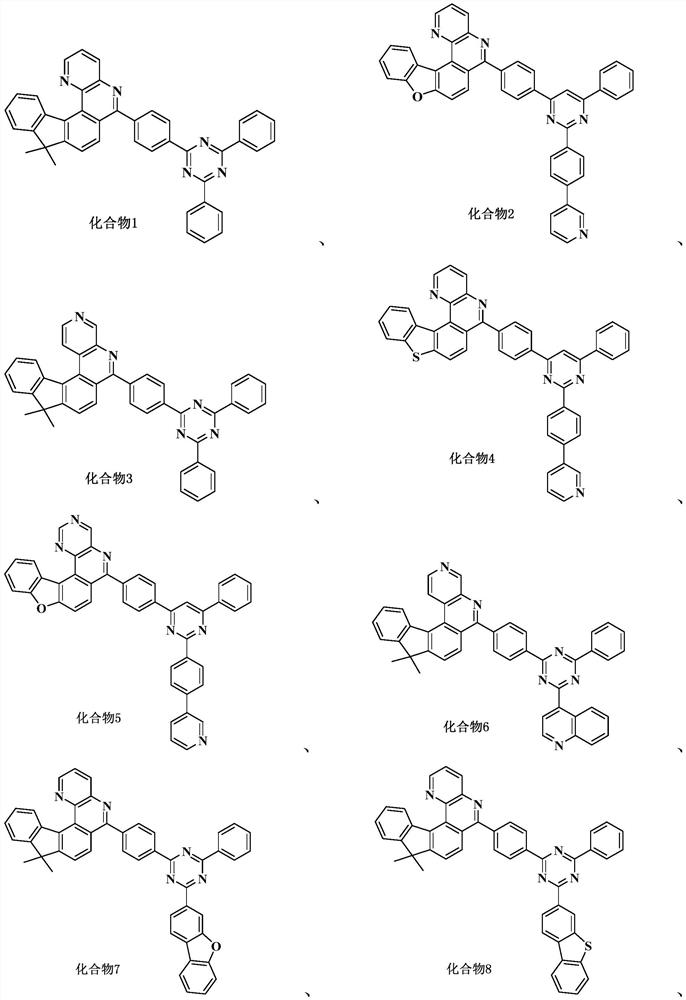

[0072] This embodiment provides an electroluminescent compound with the following structure:

[0073]

[0074] The preparation method of compound 1 is as follows:

[0075]

[0076] Mix 3g of compound 1a, 6g of anhydrous potassium phosphate powder and 100mL of anhydrous 1,4-dioxane, and feed nitrogen gas while vacuuming, so that the reaction is in a nitrogen atmosphere, and add 0.3g of catalyst four ( Triphenylphosphine) palladium Pd (PPh 3 ) 4 and 2.5 g of 2,4-diphenyltriazineboronic acid, stirred and refluxed for 36 h, and the reaction was detected by thin-layer chromatography to be almost complete, and then by column chromatography, 2.1 g of the target product was obtained (yield 46%).

[0077] Characterization results of compound 1: the melting point T of compound 1 was measured by thermogravimetric analysis (TGA) m It is 320°C, and its purity is 99.9% as measured by high performance liquid chromatography (HPLC);

[0078] 1 H NMR (400MHz, DMSO): δ8.99(d,1H),8.41(...

Embodiment 2

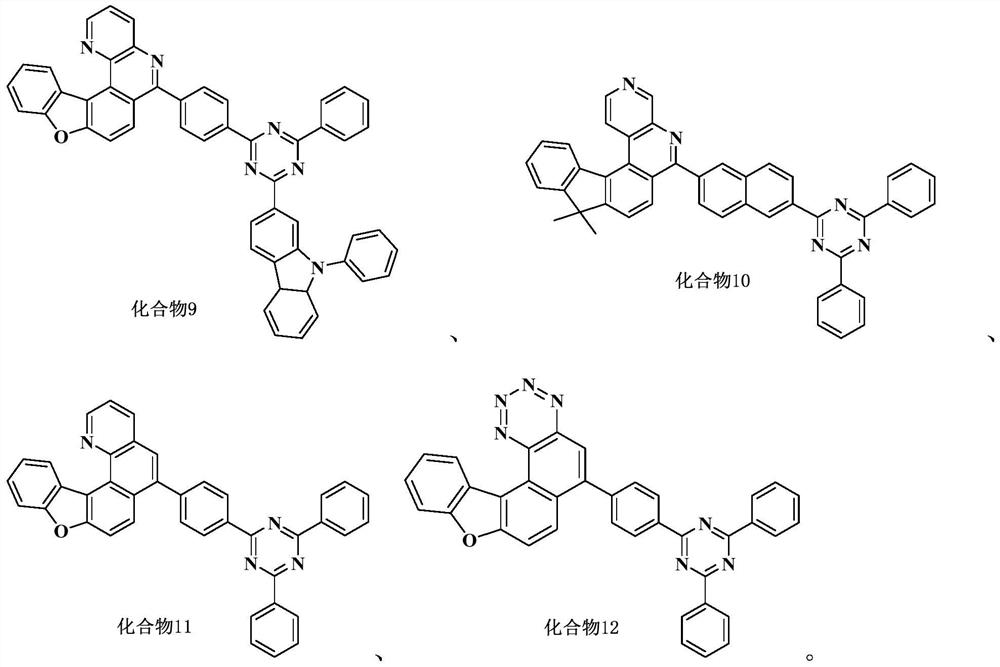

[0080] This embodiment provides an electroluminescent compound with the following structure:

[0081]

[0082] The preparation method of compound 2 is as follows:

[0083]

[0084] Mix 2.82g of compound 2a, 6g of anhydrous potassium phosphate powder and 100mL of anhydrous 1,4-dioxane, and pass nitrogen gas while vacuuming, so that the reaction is in a nitrogen atmosphere, and add 0.28g of catalyst IV at 100°C. (Triphenylphosphine)palladiumPd(PPh 3 ) 4 and 2.91 g of compound 2b, stirred and refluxed for 36 h, and the reaction was detected by thin layer chromatography to be almost complete, and then by column chromatography, 2.9 g of the target product was obtained (yield 47%).

[0085] Characterization results of compound 2: The melting point T of compound 2 was measured by TGA m It is 340°C, and its purity measured by HPLC is 99.9%;

[0086] 1 H NMR (400MHz, DMSO): δ8.99(d,1H),8.81(s,1H),8.55(d,1H),8.41(d,1H),8.05(d,2H),7.91(d,1H ),7.87(d,1H),7.60(m,1H),7.57(d,2H),...

Embodiment 3

[0088] This embodiment provides an electroluminescent compound with the following structure:

[0089]

[0090] The preparation method of compound 3 is as follows:

[0091]

[0092] Mix 3g of compound 3a, 6g of anhydrous potassium phosphate powder and 100mL of anhydrous 1,4-dioxane, and feed nitrogen gas while vacuuming, so that the reaction is in a nitrogen atmosphere, and add 0.3g of catalyst four ( Triphenylphosphine) palladium Pd (PPh 3 ) 4 and 2.91 g of 2,4-diphenyltriazineboronic acid, stirred and refluxed for 36 h, and the reaction was detected by thin layer chromatography to be almost complete, and then by column chromatography, 2.3 g of the target product was obtained (yield 45%).

[0093] Characterization results of compound 3: The melting point T of compound 3 was measured by TGA m It is 310°C, and its purity measured by HPLC is 99.9%;

[0094] 1 H NMR (400MHz, DMSO): δ9.52(s,1H),8.59(d,1H),8.06(d,1H),8.05(d,2H),7.77(d,1H),7.61(d,1H ),7.58(d,1H),7.57(d,2H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com