Preparation method and application of modified guar gum for preparing reactive printing paste

A technology of reactive printing and guar gum, used in dyeing, textiles and papermaking, etc., can solve the problems of hard hand feeling and low printing color yield, and achieve the effects of high grafting efficiency, high depaste rate and molecular weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

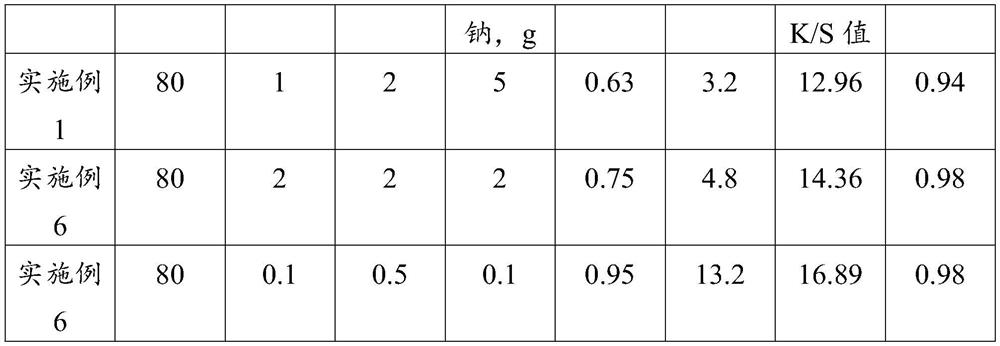

Examples

Embodiment 1

[0024] A preparation method for preparing modified guar gum for reactive printing paste, comprising the steps of:

[0025] 1) Alkalization reaction: Add aqueous sodium hydroxide solution to 100g of guar gum, and basify for 90min at 20°C to obtain an alkalization reaction solution; wherein, 20g of sodium hydroxide and 90g of water; aqueous solution of sodium hydroxide A mixture of tetramethylammonium chloride, tetramethylammonium bromide and tetraethylammonium chloride is added, and the quality of the mixture is 1g;

[0026] 2) Modification: Add sodium chloroacetate aqueous solution to the alkalization reaction solution obtained in step 1), etherify at 45°C for 300 minutes, then add bromododecane in acetone, and etherify at 45°C for 120 minutes , add hydrogen peroxide after the reaction, and oxidize and degrade at 45°C for 50 minutes to obtain a modified solution; wherein, the added amount of sodium chloroacetate is 10 g, and the quality of water is 50 g; the added amount of br...

Embodiment 2

[0029] A preparation method for preparing modified guar gum for reactive printing paste, comprising the steps of:

[0030] 1) Alkalization reaction: add potassium hydroxide aqueous solution to 100g guar gum, under the condition of 65 ℃, alkalization 30min, obtain alkalization reaction solution; Wherein, the add-on of potassium hydroxide is 45g, and the add-on of water is 60g, tetraethylammonium bromide, tetrabutylammonium chloride, tetrabutylammonium bromide, dodecyltrimethylammonium chloride, dodecyltrimethylammonium bromide are added to potassium hydroxide aqueous solution A mixture of ammonium, and the addition amount of the mixture is 0.01g;

[0031] 2) Modification: Add an aqueous solution of sodium 2-chloroethylsulfonate to the alkalization reaction solution obtained in step 1), etherify at 75°C for 30 minutes, then add bromotetradecane solution, After the etherification reaction was completed for 50 minutes, hydrogen peroxide was added and oxidatively degraded at 75°C ...

Embodiment 3

[0034] A preparation method for preparing modified guar gum for reactive printing paste, comprising the steps of:

[0035]1) Alkalization reaction: add sodium hydroxide aqueous solution to 100g guar gum, under the condition of 25 ℃, alkalization 80min, obtain alkalization reaction solution; Wherein, the add-on of sodium hydroxide is 23g, and the add-on of water is 70g, sodium hydroxide aqueous solution is added with tetradecyltrimethylammonium chloride, tetradecyltrimethylammonium bromide, hexadecyltrimethylammonium chloride, cetyltrimethylammonium bromide A mixture of ammonium, octadecyltrimethylammonium chloride, and octadecyltrimethylammonium bromide, and the addition amount of the mixture is 0.03g;

[0036] 2) Modification: Add an aqueous solution of 3-chloro-2-hydroxypropyl sulfonate sodium to the alkalization reaction solution obtained in step 1), etherify at 50°C for 70 minutes, and then add hexadecane bromide in acetone Solution, etherification reaction at 50°C for 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com