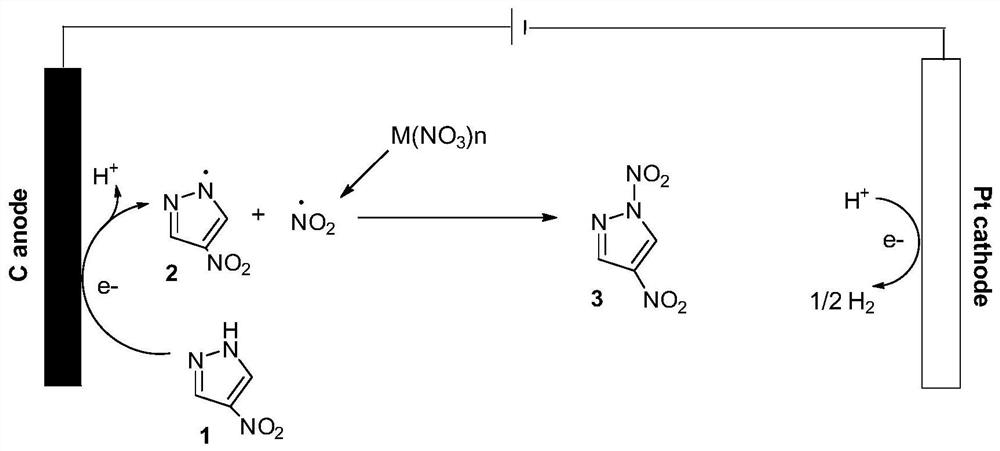

Method for preparing 1,3,5-trinitropyrazole by electrochemical method

A technology for nitropyrazole and dinitropyrazole, which is applied in the field of electrochemical synthesis of 1,3,5-trinitropyrazole, can solve the problems of difficult post-processing, many side reactions, and high reaction cost, and achieves The effect of good substrate universality, high yield and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

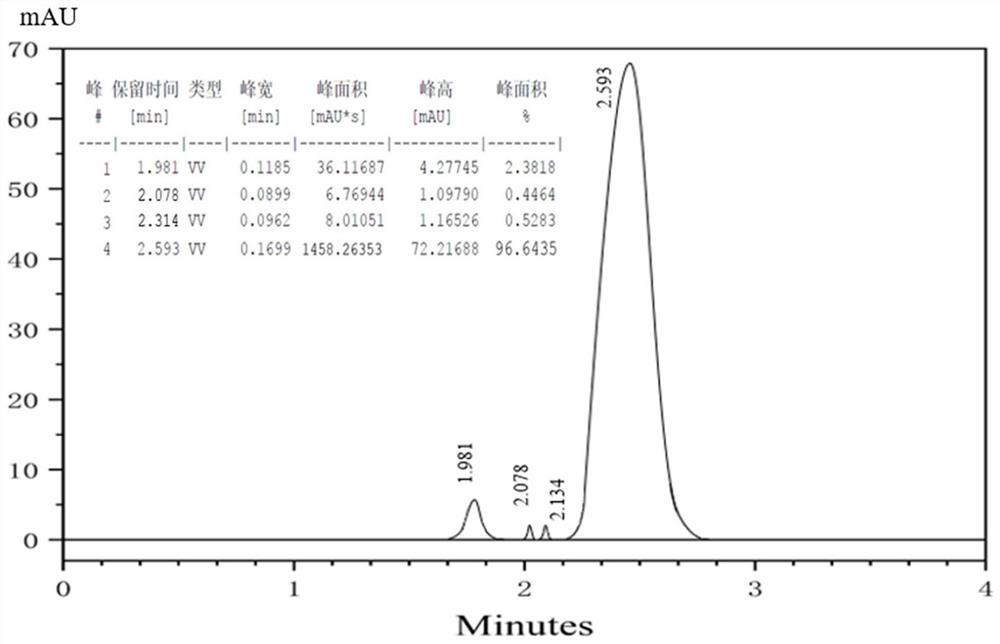

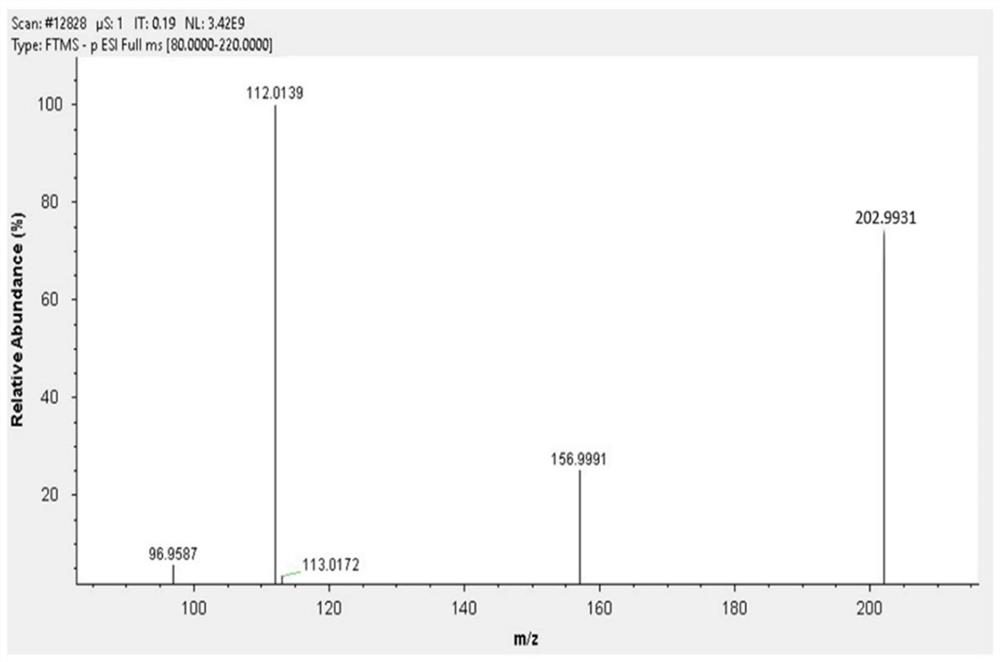

Embodiment 1

[0026]

[0027] Under stirring at room temperature, slowly add 1.5 g of 1,3-dinitropyrazole into a flask containing 12 mL of o-dichlorobenzene, raise the temperature in the sand bath to 175 ° C, and stir at constant temperature for 8 h. After the reaction is completed, the reaction solution is cooled to Cool in an ice-water bath at room temperature, filter under reduced pressure to obtain the crude product of C-nitropyrazole, add an appropriate amount of diethyl ether to the crude product, reflux and stir for 0.5h, cool down in an ice-water bath and filter, remove diethyl ether in a vacuum, and obtain relatively pure 3,5-nitropyrazole base pyrazole.

Embodiment 2

[0029] Other conditions are the same as in Example 1, and the experiments of different reaction times are checked, and the experimental results are shown in Table 1.

[0030] The influence of table 1 reaction time on productive rate

[0031]

Embodiment 3

[0033] Other conditions are the same as in Example 1, and the experiments of different reaction temperatures are checked, and the experimental results are shown in Table 2.

[0034] The influence of table 2 temperature of reaction on productive rate

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com