Synchronous forming method for anti-corrosion protection layer of cast-in-situ bored pile

A technology of bored piles and protective layers, which is applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problem of no effective anti-corrosion measures for pile foundations, and achieve a remarkable anti-corrosion effect, improve compactness, and improve bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for synchronously forming the anticorrosion protection layer of bored piles described in this embodiment includes the following steps:

[0027] a. Hole forming work: Carry out conventional bored pile hole forming work.

[0028] b. Determine the specifications of the annular grouter 5: select an appropriate size annular grouter 5 according to the design diameter of the cast-in-place pile. If it is less than or equal to the diameter of the drilled hole, it is required that the thickness of the anti-corrosion protection layer formed by the annular grouter 5 after grouting is not less than 1cm.

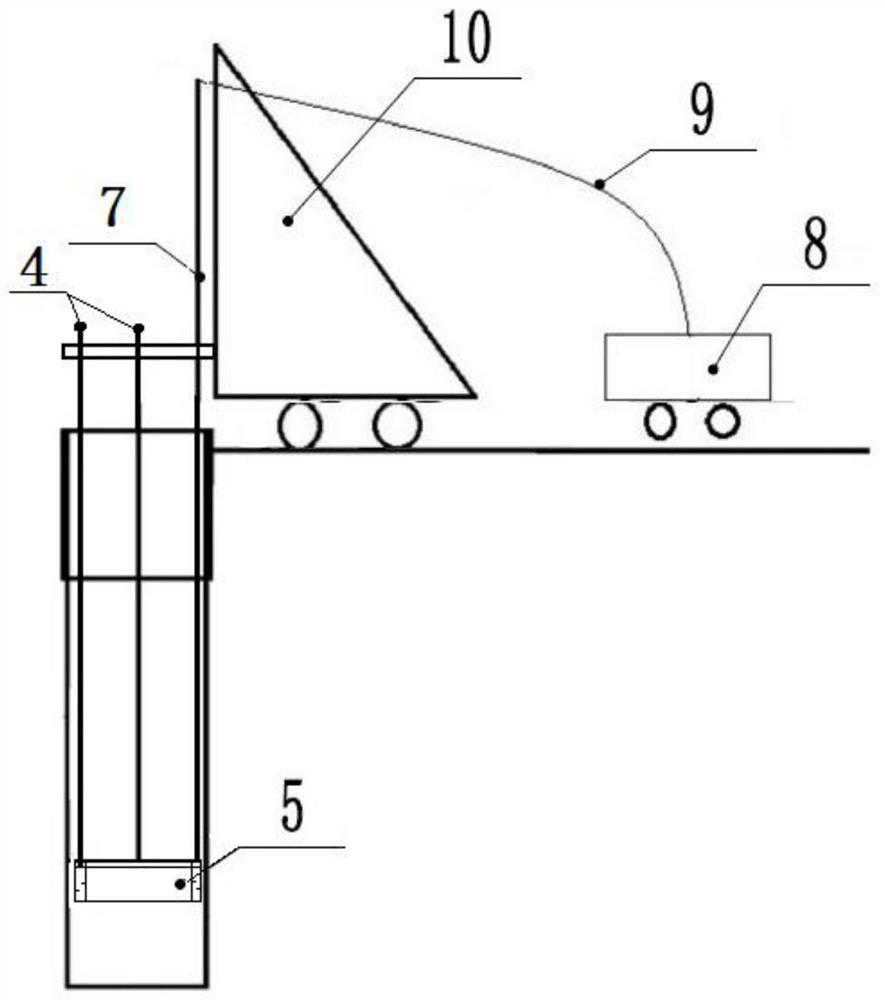

[0029] c. Check whether the component connection and the grouting channel are smooth: check whether the connection between the grouting machine 8 and the grouting pipe 7, the grouting pipe 7 and the annular grouter 5, the lifting rod 4 and the annular grouter 5 is tight; Check whether the grouting channel is unobstructed by pre-compressing a certain amount of grout, and...

Embodiment 2

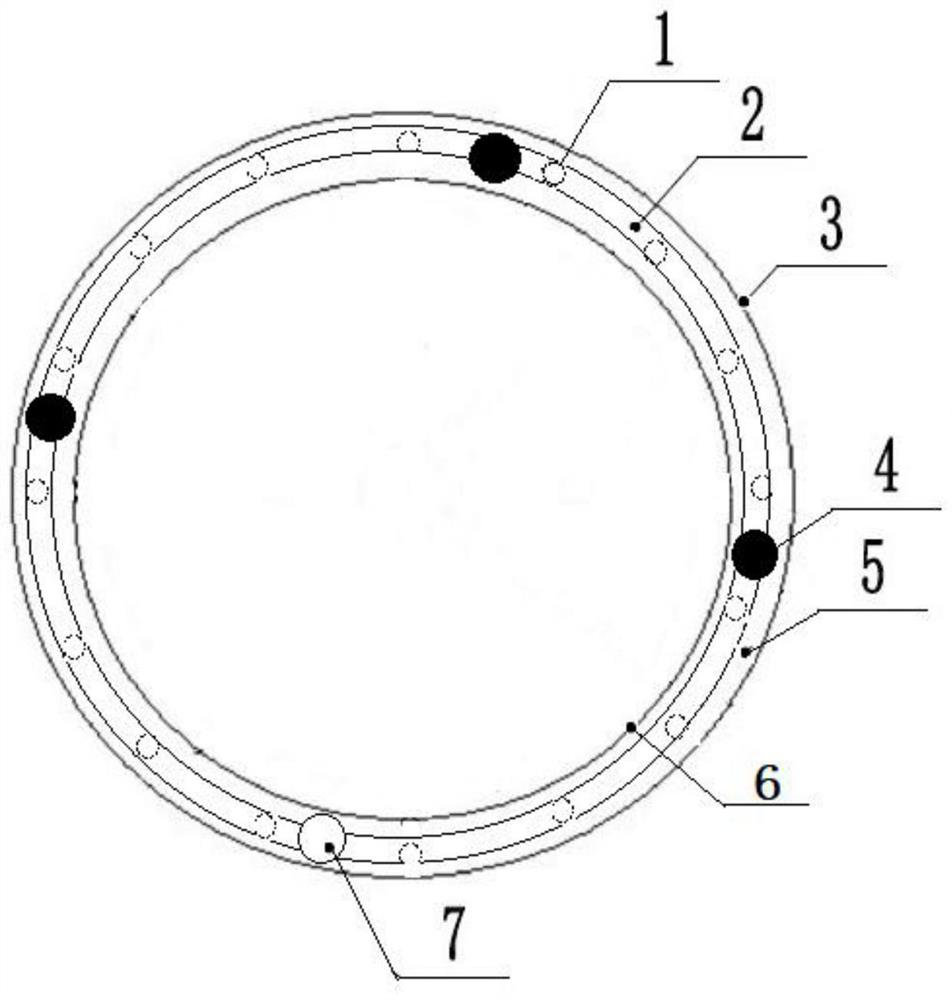

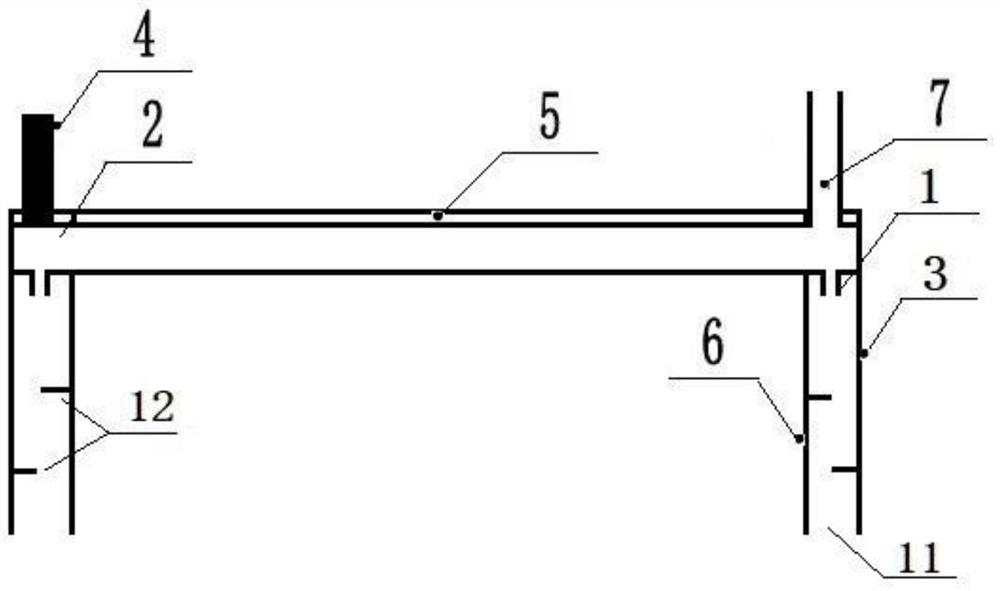

[0040] A device for synchronously forming the anticorrosion protection layer of bored piles for implementing the method described in Example 1, comprising an annular grouting device 5, a lifting rod 4, a grouting pipe 7 and a nozzle 1; the upper end of the grouting pipe 7 passes through The grout delivery pipe 9 is connected with the grouting machine 8, the lower end is fixedly connected with the annular grouter 5, and communicates with the annular pipe 2 provided inside the annular grouter 5; the bottom circumference of the annular pipe 2 is provided with a plurality of nozzles 1 , the nozzle 1 communicates with the inside of the annular pipe 2, and the bottom of the annular grouter 5 is a grout outlet 11, and the anti-corrosion slurry is injected into the grouting pipe 7 through the grouting machine 8, and thus enters the annular grouter 5, and the sprayer 1. Pour anti-corrosion grout into the hole; the lifting rod 4 is connected with the annular grouter 5 for lifting the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com