Light beam direction calibration method of optical measuring head in spectrum confocal measurement system

A measurement system and spectral confocal technology, which is applied in the field of beam calibration of the optical probe of the spectral confocal measurement system, can solve the problem that the direction of the beam is not perpendicular to the surface of the measured object, etc., so that the calibration method is simple and easy to operate, reducing difficulty, The effect of improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

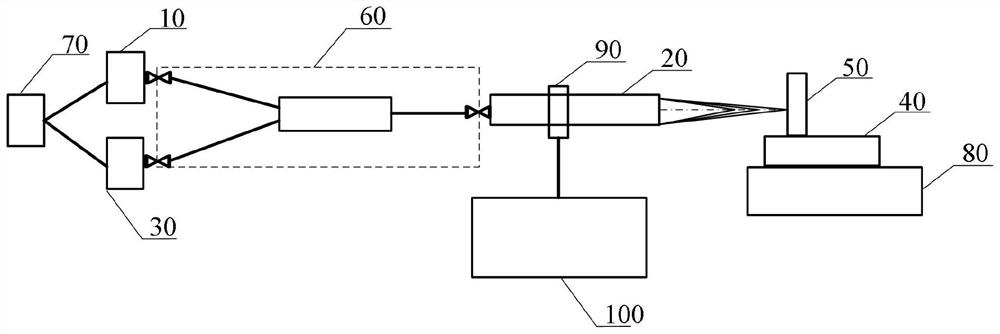

[0030] In this example, if figure 1 As shown, the spectral confocal measurement system is provided with an optical probe 20 through a fixture 90 on a four-axis precision translation stage 100, and the beam receiving end of the optical probe 20 is connected to the light source 10 and the spectrometer 30 through a Y-shaped fiber coupler 60, respectively. connected, and the controller 70 controls the light source 10 and the spectrometer 30; the beam dispersion end of the optical probe 20 faces the surface of the object to be measured 50 on the precision linear displacement stage 40, and the precision linear displacement stage 40 is placed on the rotary table 80 ;

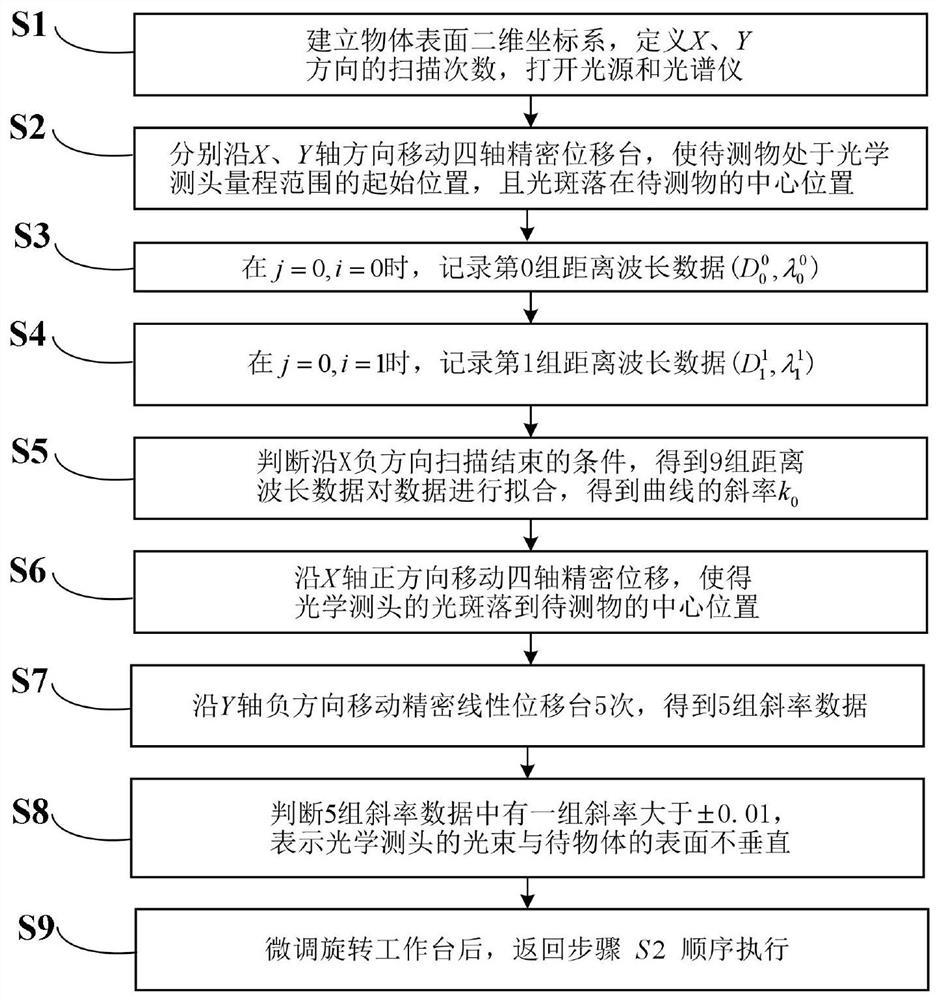

[0031] A beam direction calibration method of an optical probe in a spectral confocal measurement system, such as image 3 shown, including the following steps:

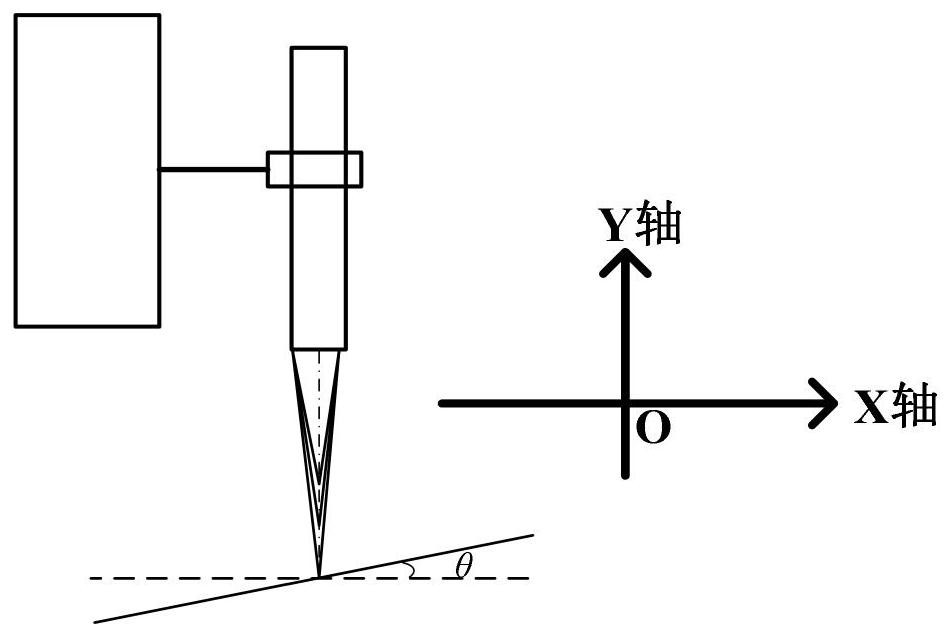

[0032] Step S1, taking the central position of the object to be measured 50 as the origin, the direction perpendicular to the surface of the object to be m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com