Broadband wide-angle anti-reflection composite micro-nano structure surface and preparation method thereof

A micro-nano structure and anti-reflection technology, which is applied in the field of optical technology and micro-nano processing, can solve the problems of decreased transmittance and inability to maintain the anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

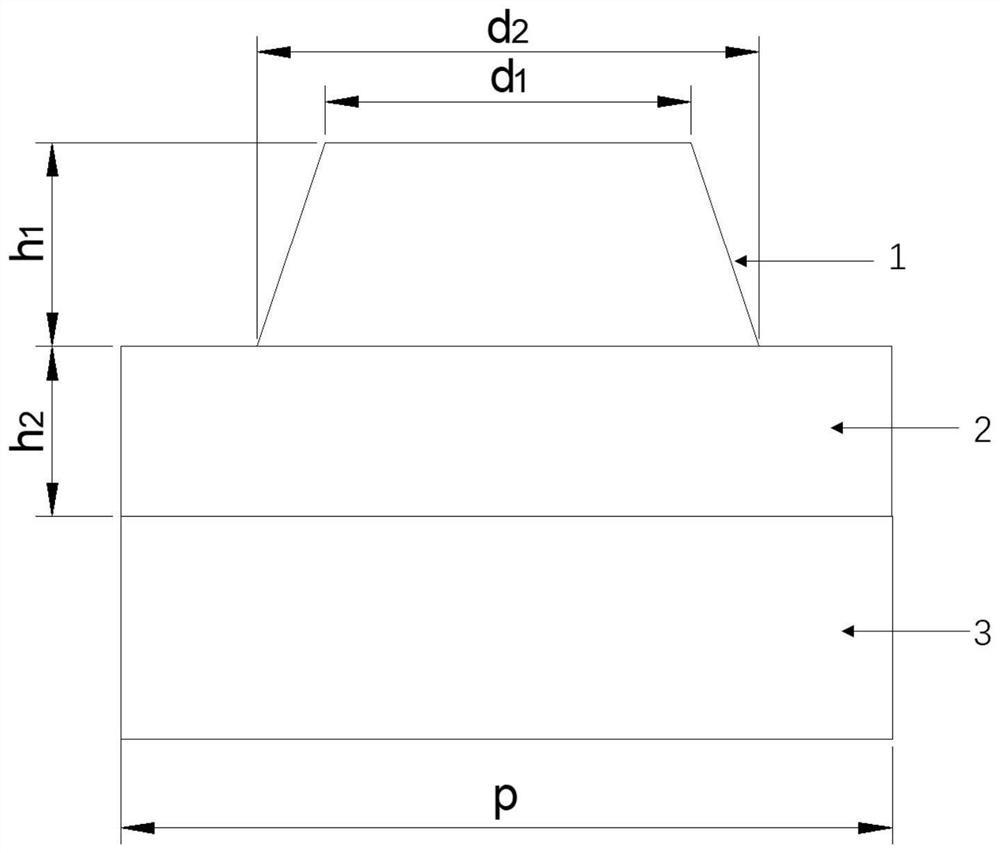

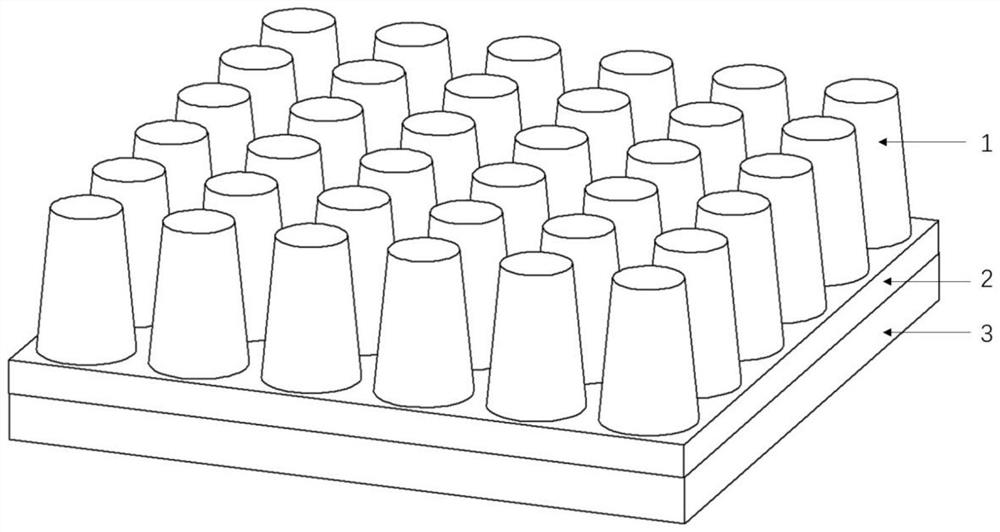

[0054] Such as Figure 1-2 As shown, a wide bandwidth angle anti-reflection composite micro-nano structure surface, which forms a single-layer optical film on the surface of the optical material substrate, and forms a certain depth of micro-nano structure on the film layer; its structure includes: micro-nano structure layer 1 , middle residual layer 2 and base layer 3 .

[0055] The micro-nano structural units are cylindrical, conical, conical, Gaussian or parabolic, etc. The shape of the unit is optimized according to the incident spectral segment and bandwidth, as well as the range of incident angles. height h 1 , top diameter d 1 , bottom diameter d 2 to describe. The equation of the micro-nano structural unit in the three-dimensional Cartesian coordinate system is: Where x, y, z represent the three-dimensional coordinates of a point on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com