Coating diaphragm, preparation method and method for inhibiting lithium dendrites

A coating and separator technology, applied in the fields of inhibiting lithium dendrites, coating separators, and preparation, can solve the problems of unstable electrode and electrolyte interface, short circuit of lithium battery/lithium ion battery, low Coulomb efficiency, etc. Effects of Li dendrite growth, avoiding safety hazards and capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

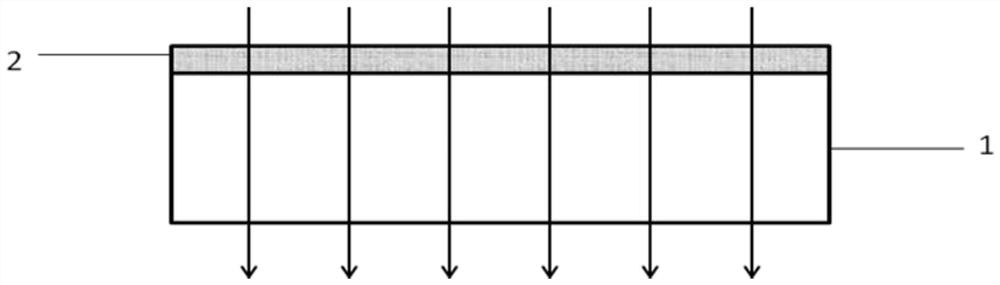

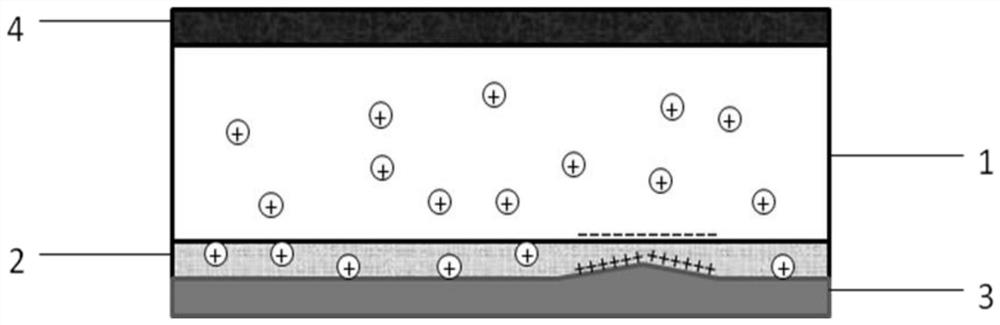

[0040]In this example, a polypropylene microporous membrane with a thickness of 20 μm and an average pore diameter of 20 nm is used as the base membrane. One surface of the base membrane is coated with polyvinylidene fluoride, and treated with a polarized electric field to form a piezoelectric polymer coating. Among them, the polypropylene microporous membrane was purchased from Celgard; the polyvinylidene fluoride (PVDF) was PVDF powder of MW ~ 534000 purchased from Sigma-Aldrich.

[0041] The concrete preparation method of the coating separator of this example is as follows:

[0042] Firstly, polyvinylidene fluoride was formulated into a coating liquid, and 10 g of polyvinylidene fluoride powder was mixed with 100 mL of DMF solvent, and stirred evenly to prepare a coating liquid.

[0043] Then, the polyvinylidene fluoride coating solution was coated on one surface of the base film by gravure coating, and the solvent was removed by drying; the coating amount was controlled to...

Embodiment 2

[0049] In this example, on the basis of Example 1, different base films, different piezoelectric polymer materials and different piezoelectric polymer coating thicknesses were tested, as detailed below:

[0050] Test 1: The polyvinylidene fluoride in Example 1 was replaced by a copolymer of vinylidene fluoride and chlorotrifluoroethylene in equal amounts, and the rest were the same as in Example 1;

[0051] Test 2: The polyvinylidene fluoride in Example 1 was replaced by a copolymer of vinylidene fluoride and trifluoroethylene in equal amounts, and the rest were the same as in Example 1;

[0052] Test 3: The polyvinylidene fluoride in Example 1 was replaced by a copolymer of chlorotrifluoroethylene and trifluoroethylene in equal amounts, and the rest were the same as in Example 1;

[0053] Test 4: The polyvinylidene fluoride in Example 1 was replaced by a copolymer of vinylidene fluoride, chlorotrifluoroethylene and trifluoroethylene in equal amounts, and the rest were the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com