Plasma generator with metal wire structure embedded in propellant powder

A plasma and metal wire technology, applied in the field of plasma, can solve the problems of low ignition efficiency of plasma generators, inability to obtain more ignition materials, low plasma density, etc., achieve high-efficiency ablation and combustion-supporting effects, and improve effective Ignition substance, increasing the effect of precise regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

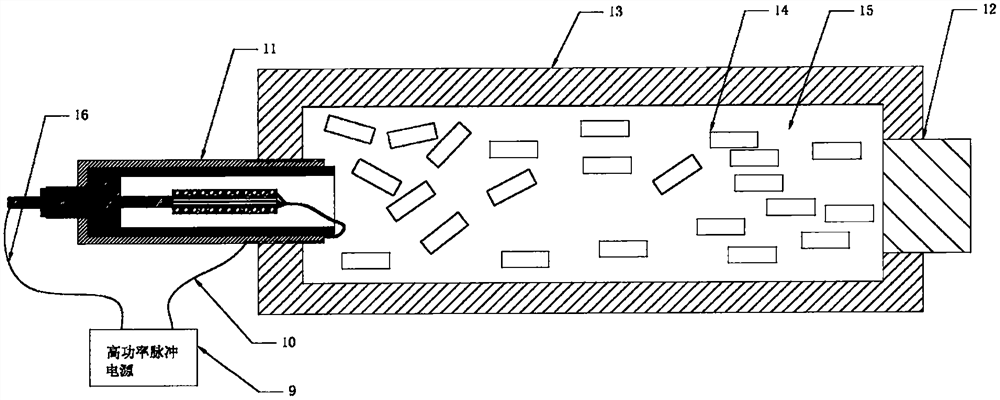

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor.

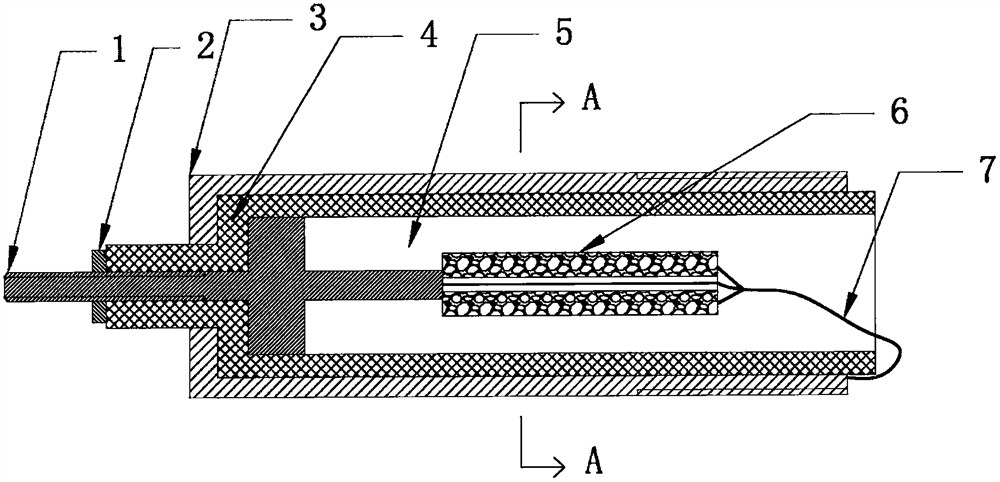

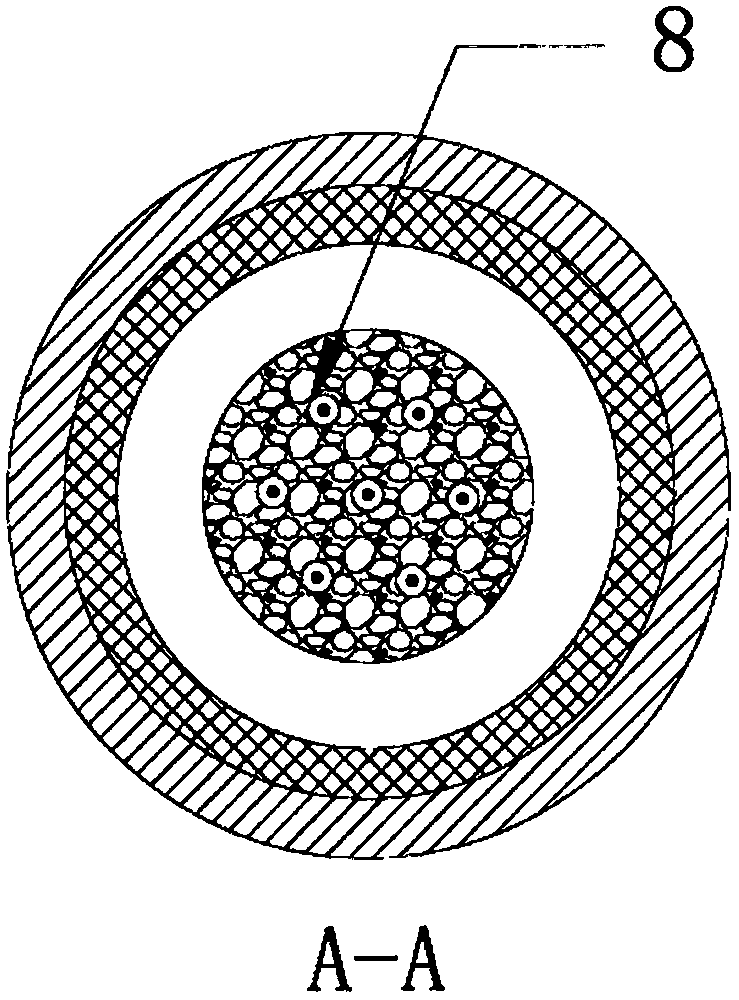

[0023] Such as figure 1 , figure 2 As shown, this embodiment provides a preferred structure of a plasma generator with a metal wire structure embedded in the propellant, including an electrode rod 1, a nut pressing piece 2, a negative electrode plug 3, a capillary tube 4, a propellant column 6, and a wire 7;

[0024] The electrode rod 1 is a structure with a disc in the middle, the material is No. 45 steel, the size of the disc is Ф20mm×5mm, the size of the rod at the left end of the disc is Ф8mm×100mm, and there is an external thread on the outer end surface for connecting with the nut. The pressing tablet 2 is connected, the rod size at the right end of the disk is Ф8mm×50mm, the right end of the disk is fixed with the propellant column 6 and the metal wire 7, and the left end of the disk is pressed against the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com