Formaldehyde decomposing agent and preparation method thereof

A formaldehyde decomposition and extraction technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as high light requirements, inability to achieve formaldehyde, and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

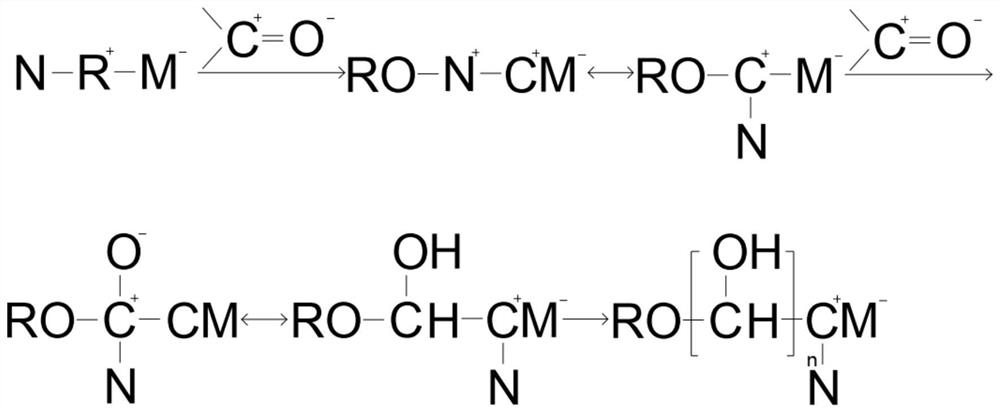

Method used

Image

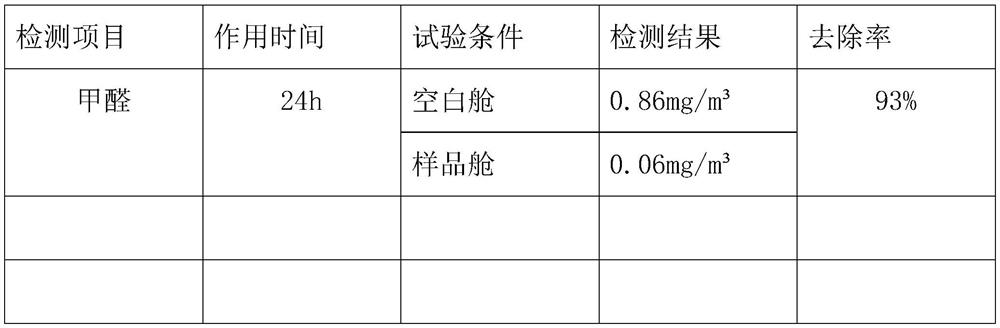

Examples

Embodiment 1

[0022] The preparation example of a formaldehyde decomposing agent specifically includes the following components by weight: 15 parts of pothos rhizome extract, 10 parts of apple extract, 3 parts of plant active enzyme, 8 parts of potassium and sodium ion chelate, surfactant 4 parts, 2 parts of edible salt, 2 parts of edible alkali, 60 parts of deionized water.

[0023] Concrete preparation steps are:

[0024] S1. Put the rhizome of the pothos radish with a water content lower than 60% into 2 times the volume of 95% ethanol solution for extraction, and extract with an ultrasonic extractor, extract at least 3 times, and extract for 30 minutes each time. The apple extract is extracted according to the method of the extract of the rhizome of the pothos, and the liquid extract of the rhizome of the pothos and the extract of the apple can be obtained.

[0025] S2, mixing powdered potassium carbonate and liquid chelating agent to prepare potassium ion chelate, wherein, the chelatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com