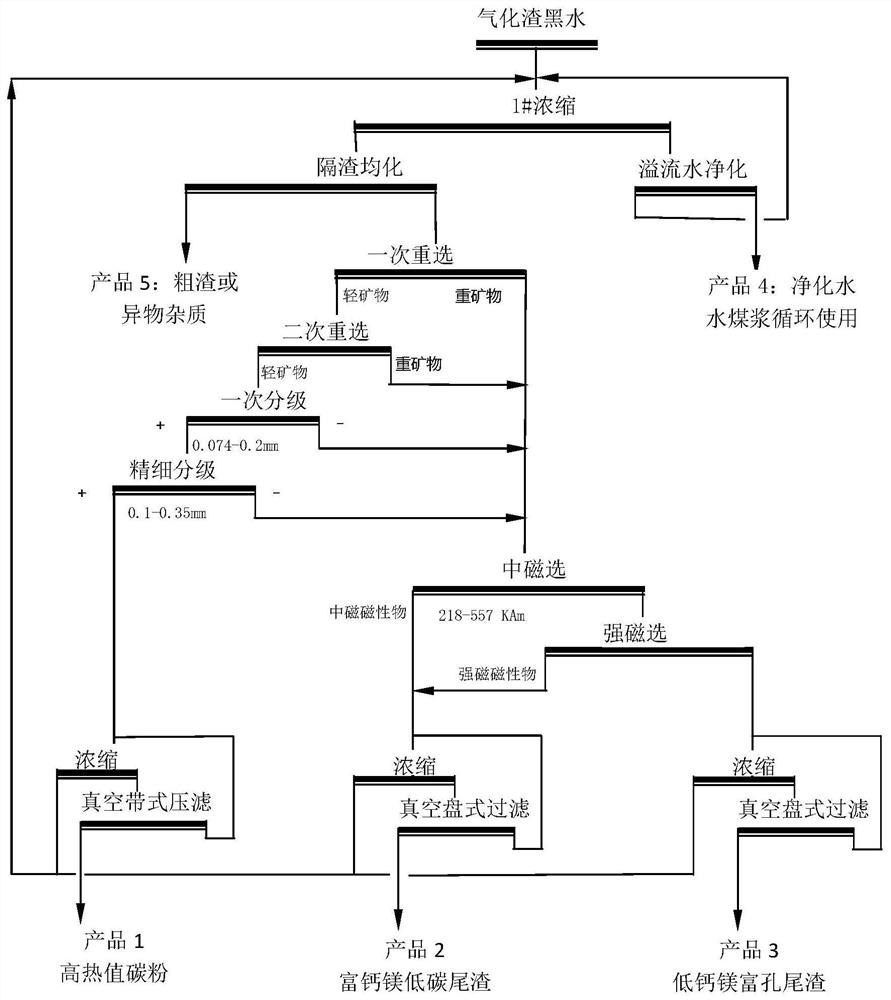

Gasified black water fine slag residual carbon recovery-tailing calcium and magnesium content reduction method

A technology for fine slag and tailings, which is used in the recovery of carbon residues in Texaco furnace gasification black water fine slag and the reduction of calcium and magnesium content in tailings after carbon extraction, and the recovery of carbon residues in coal chemical gasification blackwater fine slag-tails In the field of calcium and magnesium slag reduction, it can solve the problems of high content of calcium and magnesium alkaline minerals in tailings, which cannot be comprehensively utilized, and difficult to recover carbon residue from gasification fine slag. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

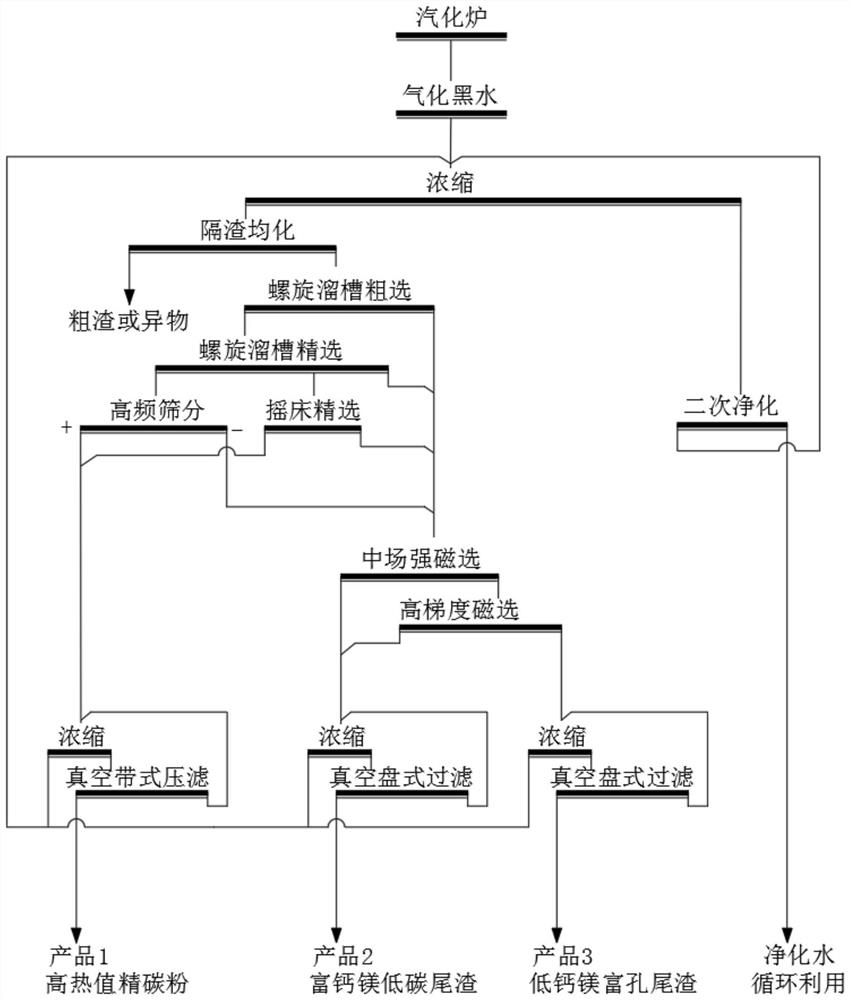

Embodiment 1

[0053] The loss on ignition of the gasification black water fine slag raw ore of a chemical company in Inner Mongolia is 48.48%, the total content of CaO and MgO is 7.08%, and other chemical components are mainly silica, alumina, and iron oxide. use figure 2 As shown in the process flow, the high-frequency screening operation obtains +0.2mm coarse-grained products and -0.2mm fine-grained products. The medium magnetic separation adopts a semi-countercurrent drum magnetic separator with a magnetic field strength of 477KA / m, and the strong magnetic separation A plate magnetic separator with a magnetic field strength of 716KA / m is used. This embodiment has obtained three kinds of products altogether, wherein product 1: productive rate is 40.98%, the loss on ignition is 81.31%, the total content of calcium oxide and magnesium oxide is 2.07%, the carbon recovery rate is 67.36% high-quality fine carbon powder , the product can be dehydrated and dried to achieve circular gasificatio...

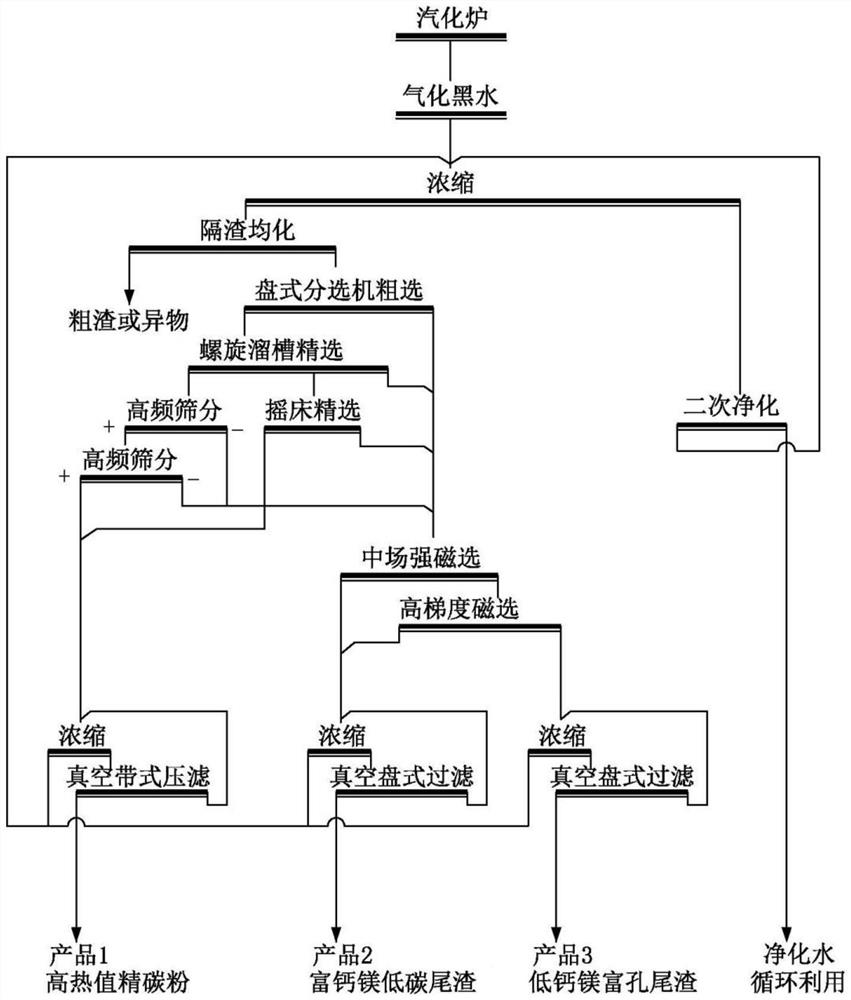

Embodiment 2

[0059] The loss on ignition of the raw ore of gasification black water fine slag in a chemical company in Ningxia is 36.40%, the total content of CaO and MgO is 6.35%, and the other chemical components are mainly silica, alumina, and iron oxide. image 3 As shown in the process flow, a grading high-frequency screening operation obtains +0.074mm coarse-grained products and -0.074mm fine-grained products, and a fine-graded high-frequency screening operation obtains +0.2mm coarse-grained products and -0.2mm mm fine-grained products, the medium magnetic separation uses a semi-countercurrent drum magnetic separator with a magnetic field strength of 557KA / m, and the strong magnetic separation adopts a high-gradient strong magnetic separator with a magnetic field strength of 1195KA / m. Present embodiment has obtained three kinds of products altogether, and wherein product 1: productive rate is 30.07%, loss on ignition is 82.11%, recovery rate is 67.02% carbon concentrate, and wherein c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com