Method for extracting carbon from gasified slag through wet method and recovering glass beads through dry method

A technology of glass microspheres and dry recovery, which is applied in chemical instruments and methods, wet separation, glass recovery, etc., can solve the problems of glass microspheres that are difficult to recycle, cannot be comprehensively utilized, gasification of fine slag and residual carbon, etc., and achieve Low cost, easy operation, high ignition loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

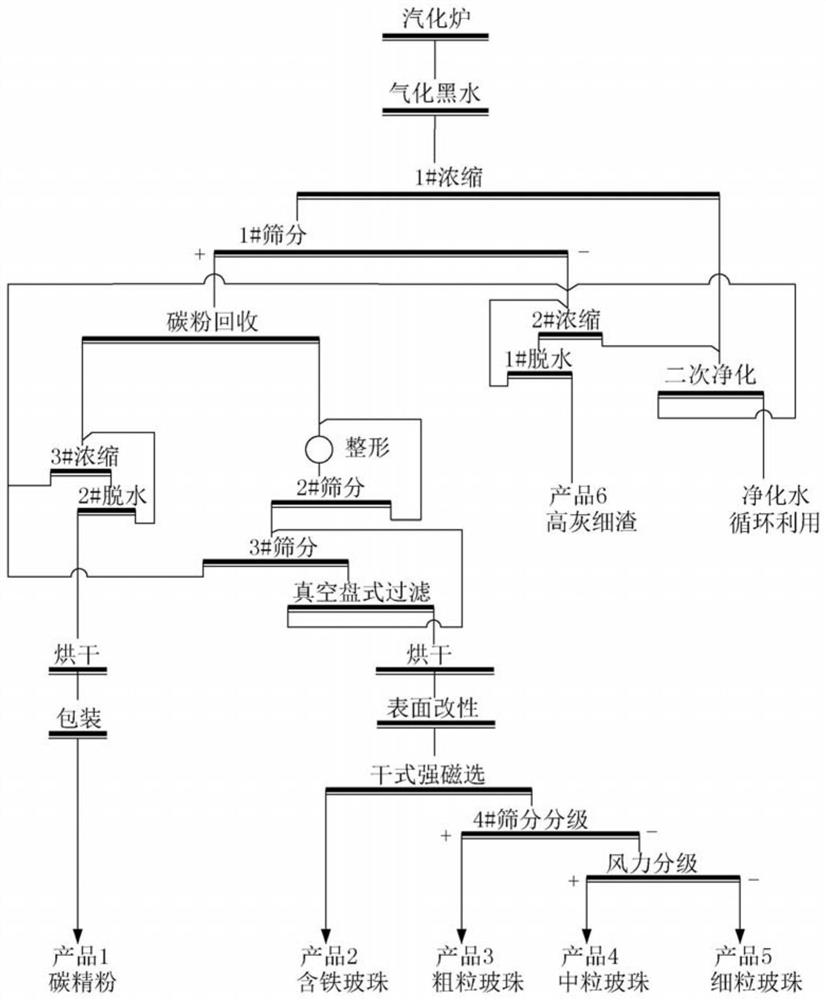

[0044] The aperture of 1# screening is 0.074mm, the aperture of 2# screening is 0.5mm, and the aperture of 3# screening is 0.031mm. Two-stage magnetic separation, the first-stage magnetic separation is a belt permanent magnet magnetic separator with a magnetic field strength of 10000Gs, and the second-stage magnetic separation is a dry electromagnetic magnetic separator with a magnetic field strength of 12000Gs. use figure 1 As shown in the process flow, the loss on ignition of the gasification black water fine slag raw ore of a chemical company in Inner Mongolia is 35.94%, Fe 2 o 3 The content is 9.39%, and other chemical components are mainly silicon dioxide, aluminum oxide, and iron oxide. The following products were obtained:

[0045] Product 1 enriched carbon powder: the yield is 32.78%, the loss on ignition is 82.45%, Fe 2 o 3 The content is 1.72%, and the carbon recovery rate is 75.19% of high-quality carbon powder. After dehydration and drying, this product can re...

Embodiment 2

[0049] This embodiment is basically the same as Embodiment 1, the difference is that the dry magnetic separation is divided into two stages of magnetic separation, the non-magnetic objects of one stage of magnetic separation enter into the second stage of magnetic separation, and the one stage of magnetic separation is belt type permanent magnetic separation machine, the magnetic field strength is 5000Gs, and the second-stage magnetic separation is a dry electromagnetic magnetic separator with a magnetic field strength of 15000Gs.

Embodiment 3

[0051] This embodiment is basically the same as Embodiment 1, the difference is that the dry magnetic separation is divided into two stages of magnetic separation, the non-magnetic objects of one stage of magnetic separation enter into the second stage of magnetic separation, and the one stage of magnetic separation is belt type permanent magnetic separation machine with a magnetic field strength of 8000Gs, and the second-stage magnetic separation is a dry electromagnetic magnetic separator with a magnetic field strength of 10000Gs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com