Composite microbial agent for treating high-COD cutting fluid waste liquid and technique

A compound bacterial agent and waste liquid treatment technology, applied in microorganism-based methods, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of cutting fluid waste liquid treatment, waste of time and cost of enterprises, and reduce time cost, time-efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First, 450 g of Bacillus subtilis, 100 g of Pseudomonas aeruginosa, 50 g of Pseudomonas stutzeri, 150 g of Stenotrophomonas maltophilia, 150 g of Acinetobacter johnsonii, and 100 g of Pseudomonas putida were configured in proportion; At the same time, prepare 4.5 g of carbohydrate protective agent glucose, 0.2 g of protein protective agent serum albumin, 0.2 g of amino acid salt protective agent sodium glutamate, and 0.1 g of mixed protective agent skim milk with 5 g of distilled water in proportion to form a composite protective agent; then mix the mixed bacterial liquid and protective agent evenly, ferment at 34°C for 48 hours, vacuum freeze-dry and pulverize to make a composite bacterial agent.

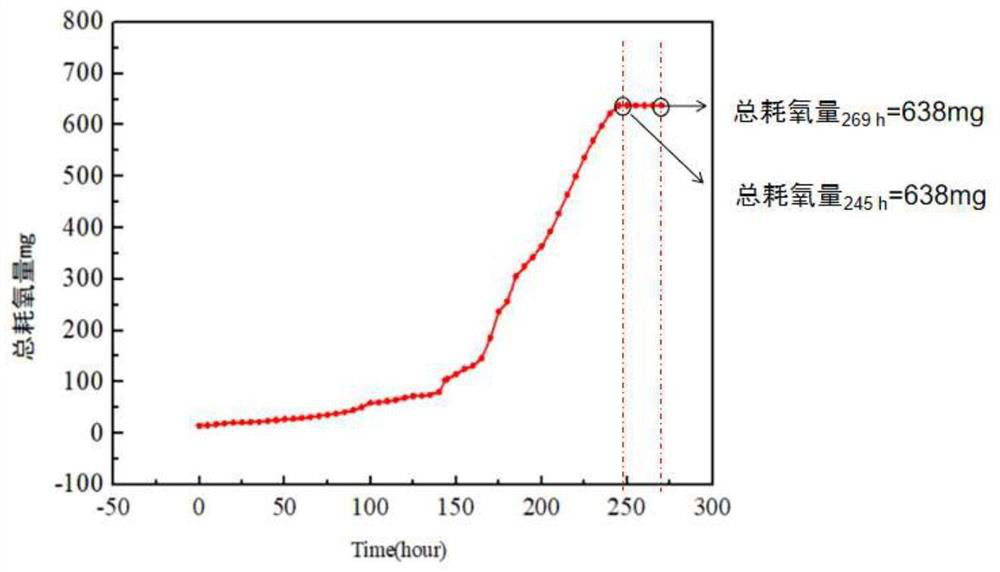

[0035] The composite bacteria agent prepared by this patent is used to treat the cutting fluid waste liquid of a metal processing enterprise in Tianjin. Waste liquid COD value: 113792mg / L. Add a compound bacterial agent with a mass fraction of 1%, and use a biorespiration r...

Embodiment 2

[0037] First, 500 g of Bacillus subtilis, 150 g of Pseudomonas aeruginosa, 100 g of Pseudomonas stutzeri, 100 g of Stenotrophomonas maltophilia, 100 g of Acinetobacter johnsonii, and 50 g of Pseudomonas putida are configured in proportion; At the same time, 4.4 g of glucose protecting agent, 0.25 g of protein protecting agent serum albumin, 0.25 g of amino acid salt protecting agent sodium glutamate, and 0.1 g of mixed protecting agent skim milk were prepared in proportion with 5 g of distilled water Then, the mixed bacterial solution and protective agent were evenly mixed, fermented at 36° C. for 40 hours, then vacuum freeze-dried and pulverized to form a composite bacterial agent.

[0038] The composite bacterial agent made by this patent is used to treat the cutting fluid waste liquid of a metal processing enterprise in Shenzhen. Waste liquid COD value: 211464mg / L. Add a compound bacterial agent with a mass fraction of 1%, and use a biorespiration rate meter to perform a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com