Construction method of glucose biosensor assembled based on glutathione

A biosensor and glutathione technology, applied in the field of biosensors, can solve the problems of undiscovered graphene oxide and glutathione biosensors, etc., and achieve good direct electrochemical behavior, good catalytic effect, and good selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of glutathione-modified gold electrodes

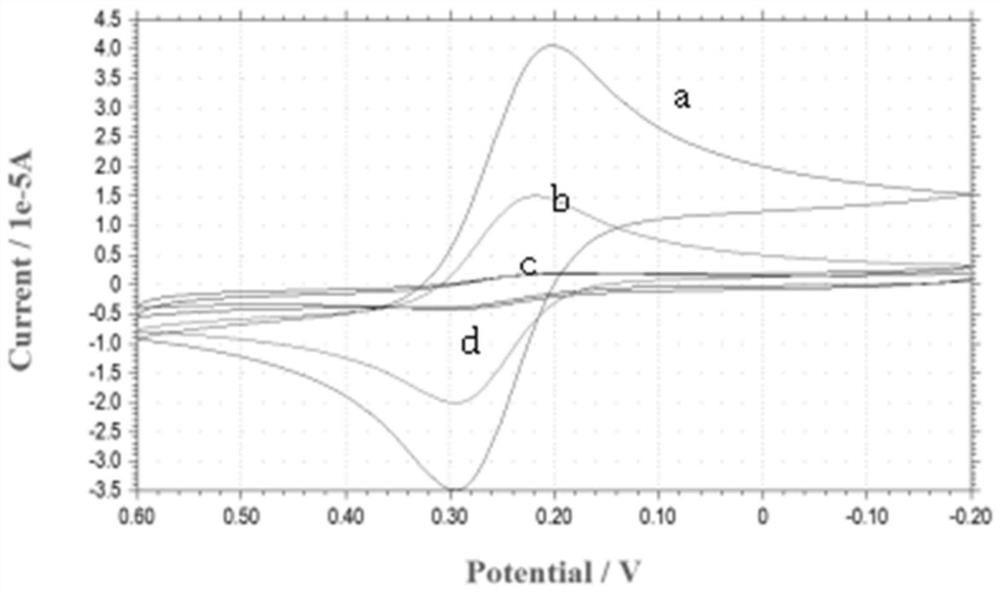

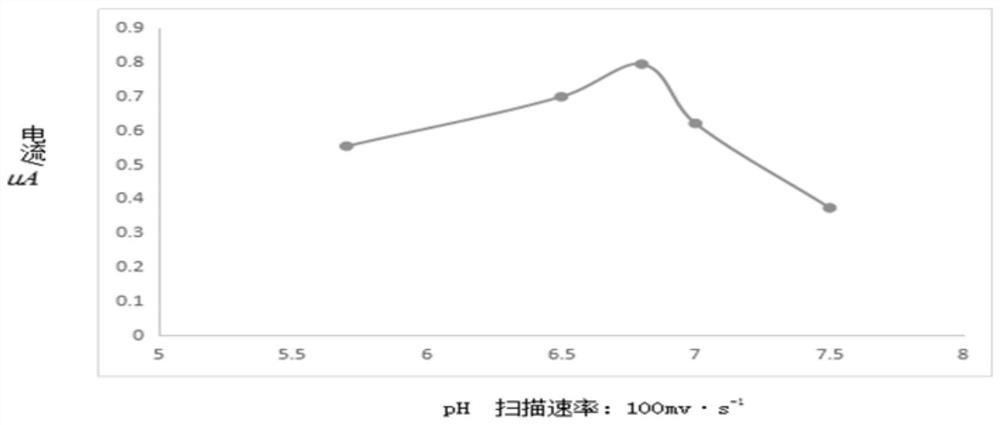

[0049] Gold electrodes with a diameter of 1.0 mm were coated with 0.05 μm Al 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, cleaned with an ultrasonic cleaner for 10 minutes, taken out and dried naturally, and ultrasonically cleaned with 75% alcohol for 10 minutes. Using cyclic voltammetry (CV) at 2.5×10 -3 Scan in mol / L potassium ferricyanide solution (containing 5.0mol / L KCl) until it is stable, and the potential difference is within 100mV.

[0050] Weigh 0.7683g glutathione and dissolve it in a phosphate buffer solution with a pH value of 7.00 to make 50mL glutathione solution with a concentration of 0.05mol / L, suspend and soak the ground gold electrode in 0.05mol / L Soak in glutathione solution for 24 hours at 4°C, and store in a refrigerator at 4°C for later use.

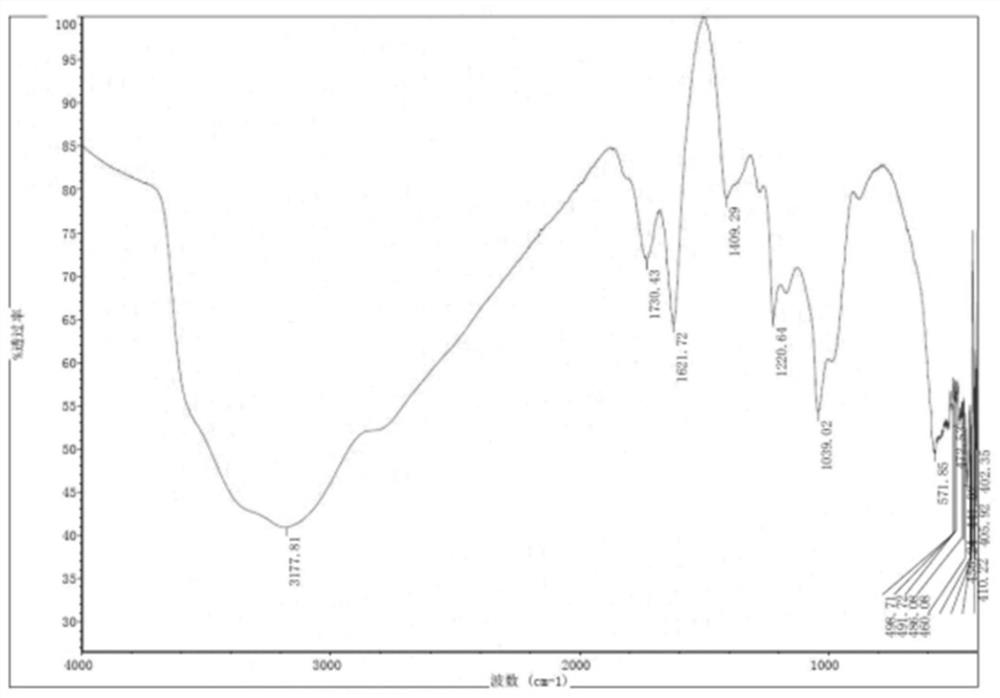

[0051] (2) Preparation of carboxylated graphene

[0052] Assemble a 250ml reaction bottle in an ice-water bat...

Embodiment 2

[0059] (1) Preparation of glutathione-modified gold electrodes

[0060] Gold electrodes with a diameter of 1.0 mm were coated with 0.06 μm Al 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, cleaned with an ultrasonic cleaner for 10 minutes, taken out and dried naturally, and ultrasonically cleaned with 75% alcohol for 10 minutes. Using cyclic voltammetry (CV) at 3.0×10 -3 Scan in mol / L potassium ferricyanide solution (containing 5.5mol / L KCl) until it is stable, and the potential difference is within 100mV.

[0061] Weigh 0.9220g glutathione and dissolve it in a phosphate buffer solution with a pH value of 7.00 to make 50mL glutathione solution with a concentration of 0.06mol / L, suspend and soak the ground gold electrode in 0.06mol / L Soak in glutathione solution for 20 hours at 4°C, and store in a refrigerator at 4°C for later use.

[0062] (2) Preparation of carboxylated graphene

[0063] Assemble a 250ml reaction bottle in an ice-water bat...

Embodiment 3

[0070] (1) Preparation of glutathione-modified gold electrodes

[0071] Gold electrodes with a diameter of 1.0 mm were coated with 0.05 μm Al 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, cleaned with an ultrasonic cleaner for 10 minutes, taken out and dried naturally, and ultrasonically cleaned with 75% alcohol for 10 minutes. Using cyclic voltammetry (CV) at 2.8×10 -3 Scan in mol / L potassium ferricyanide solution (containing 5.2mol / L KCl) until it is stable, and the potential difference is within 100mV.

[0072] Weigh 0.6146g glutathione and dissolve it in a phosphate buffer solution with a pH value of 7.00 to make 50mL glutathione solution with a concentration of 0.04mol / L, suspend and soak the ground gold electrode in 0.04mol / L Soak in glutathione solution for 24 hours at 5°C, and store in a refrigerator at 4°C for later use.

[0073] (2) Preparation of carboxylated graphene

[0074] Assemble a 250ml reaction bottle in an ice-water bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com