Millimeter wave dielectric resonator antenna module and communication equipment

A dielectric resonator and antenna module technology, applied in resonant antennas, antennas, electrical short antennas, etc., can solve the problems of DRA influence and obvious influence on the performance of feeder structure antennas, achieve low machining accuracy, reduce sensitivity, realize Effects of space feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

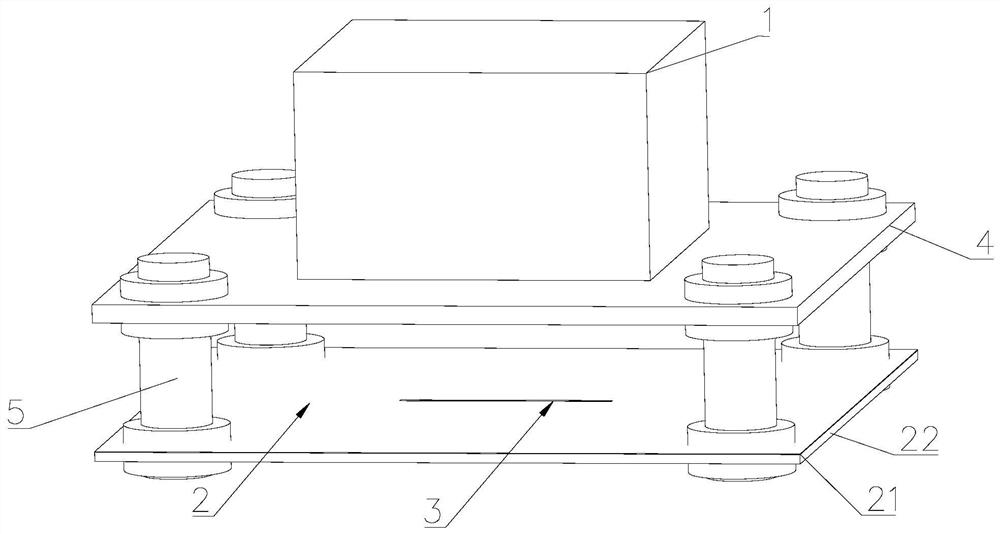

[0055] Please refer to Figure 1-3 , a millimeter-wave dielectric resonator antenna module in this embodiment, including a dielectric resonator 1 and an antenna ground 2;

[0056] The dielectric resonator 1 is arranged on one side of the antenna ground 2, and the dielectric resonator 1 is within the antenna near-field area of the antenna ground 2, and the dielectric resonator 1 and the antenna ground 2 there is a gap between

[0057] A feeding structure 3 is provided at a position corresponding to the antenna ground 2 and the dielectric resonator 1;

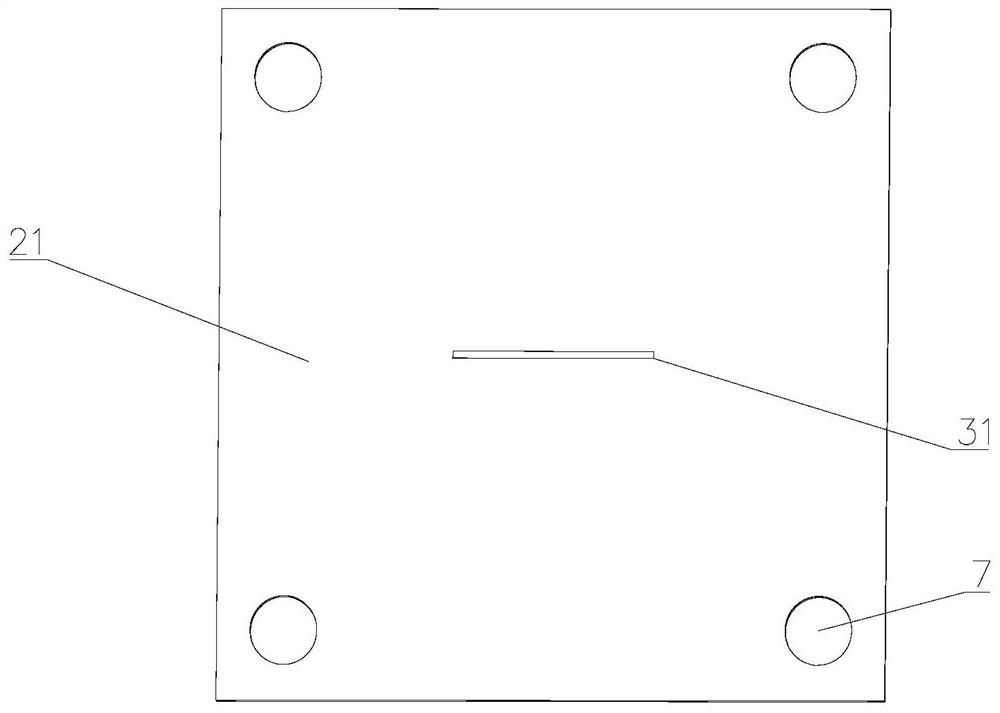

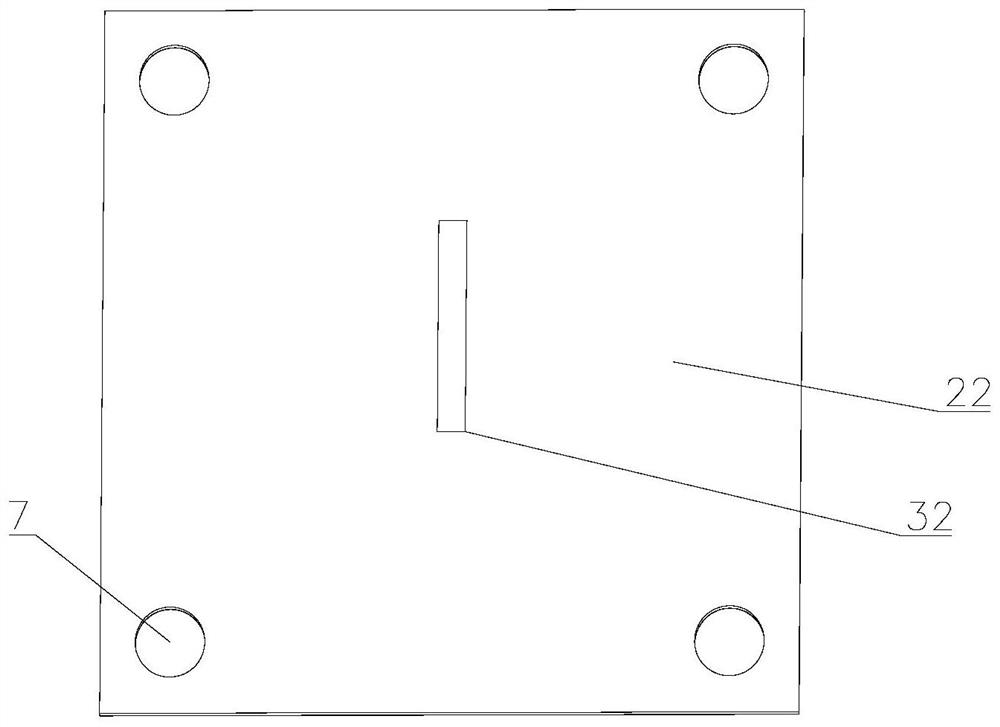

[0058] Specifically, such as figure 1 As shown, the antenna ground 2 includes a metal ground 21 and a dielectric substrate 22;

[0059] The dielectric resonator 1 is located on one side of the metal ground 21;

[0060] The dielectric substrate 22 is located on the other side of the metal ground 21;

[0061] Such as figure 2 , 3 As shown, the feed structure 3 includes a rectangular slot 31 and a microstrip line 32;

[006...

Embodiment 2

[0066] Please refer to Figure 1-12 , the difference between this embodiment and the first embodiment is that the specific structure of the dielectric resonator, the placement plate and the support is defined:

[0067] Specifically, the interval is 0.25-0.5 times the wavelength corresponding to the working frequency of the antenna;

[0068] The dielectric constant of the dielectric resonator 1 is 2.5-5;

[0069] Wherein, the shape of the dielectric resonator 1 is not limited, but the shape of the dielectric resonator 1 must be able to excite the antenna radiation mode;

[0070] In an optional implementation manner, the dielectric constant of the dielectric resonator 1 is 2.5, the shape of the dielectric resonator 1 is a cuboid, the length and width are 10 mm, and the height is 5.65 mm, such as figure 1 shown;

[0071] Such as figure 1 , 4 As shown, it also includes a placement plate 4 and a support 5;

[0072] The placement plate 4 is arranged on the side of the dielectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com