Flavor-enhanced multi-strain enzymatic fermentation hotpot condiment and preparation method thereof

A technology for enzymatic fermentation and hot pot base material, which is applied in the directions of oil-containing food ingredients, food ingredients as taste improvers, food science, etc. Easy-to-absorb, easy-to-handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) This embodiment provides a flavor-enhancing multi-strain enzymatic fermentation hot pot bottom material, including the following raw materials in parts by weight: 16 parts of animal and vegetable oils, 6 parts of dried peppers, 1 part of green pepper, 1 part of watercress, and 0.2 parts of tempeh , 0.1 part of glutinous rice, 1 part of salt, 0.2 part of pickled pepper, 0.3 part of ginger, 0.1 part of garlic, 0.5 part of umami agent, and 0.1 part of compound spice.

[0034] Preferably, the animal and vegetable oil is animal fat or vegetable oil, wherein the animal fat is tallow; the vegetable oil is at least one of rapeseed oil, salad oil, peanut oil and corn oil. In actual use, animal fat or vegetable oil is used alone, butter is used as a base for hot pot with butter, and vegetable oil is used as a base for clear oil hot pot. From a health point of view, vegetable oil contains a lot of unsaturated fatty acids and is easy to be absorbed. However, through random inte...

Embodiment 2-5

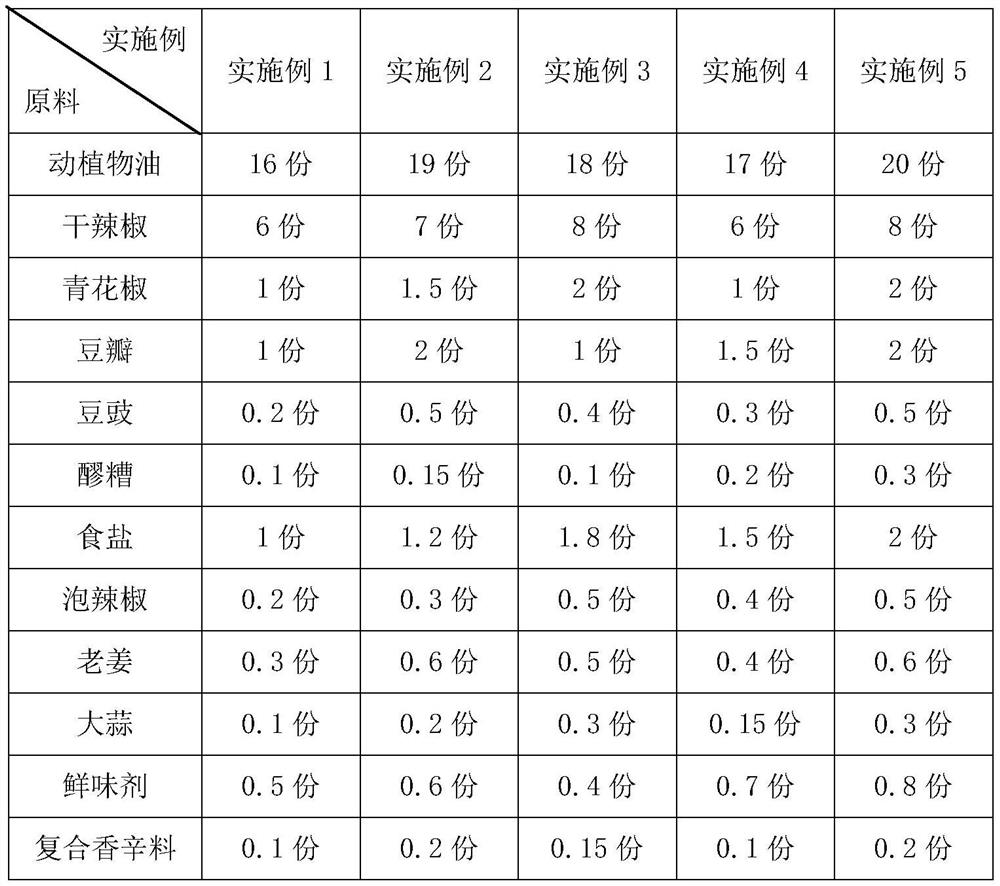

[0056] In order to screen out the best ratio of raw materials under the condition that other conditions remain unchanged, the present invention sets up embodiment 2-5, and the difference between embodiment 2-5 and embodiment 1 is only in the difference with the ratio of raw materials Table 1 shows:

[0057] Table 1 embodiment 2-5 and the raw material consumption statistical table of embodiment 1

[0058]

[0059] All the raw materials in Examples 1-5 were prepared by the processing method in Example 1, and the changes in the preparation process of each example were counted, and it was observed whether it was pasted or not. In addition, the products in each embodiment are tasted by consumers by means of questionnaire survey, and finally the hot pot bottom materials in embodiments 1-5 are comprehensively counted.

[0060] in conclusion

[0061] Situation during the preparation process: during the preparation of the hot pot bottom material, Examples 1-5 had a strong fragranc...

Embodiment 6-8

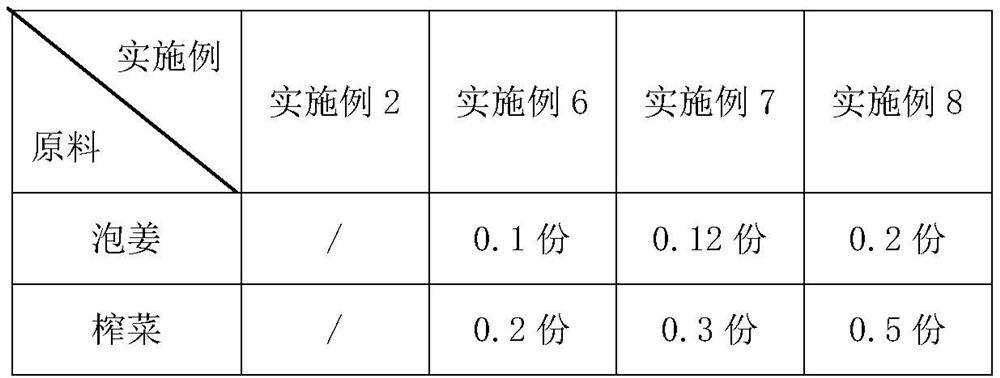

[0066] On the basis that the preferred embodiment 2 of the present invention is the best embodiment among the embodiments 1-5, the present invention has carried out a market questionnaire survey and found that most people who like to eat chafing dish also like to eat pickled ginger and pickled mustard.

[0067] On the basis that other processing conditions and raw materials are identical, the difference of raw materials in embodiment 6-8 and embodiment 2 is as shown in table 2 below:

[0068] The main difference table of raw material in the embodiment 6-8 of table 2 and embodiment 2

[0069]

[0070] The difference of preparation method among embodiment 6-8 and embodiment 2 is:

[0071] In step S3 of Example 6-8, add pickled ginger while adding watercress, tempeh, ginger and fermented glutinous rice cake chili; add pickled mustard while adding green peppercorns, compound spices, fermented glutinous rice, umami agent, salt and garlic.

[0072] The raw materials in Examples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com