DNA/RNA industrial full-automatic synthesizer

A fully automatic, synthesizer technology, applied in the control/regulation process, chemical/physical/physicochemical mobile reactors, chemical instruments and methods, etc., can solve problems affecting synthesis efficiency, synthesis carrier hanging on the wall, resin impact, etc. , to achieve the effect of improving the synthesis efficiency and solving the problem of crushing and hanging on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

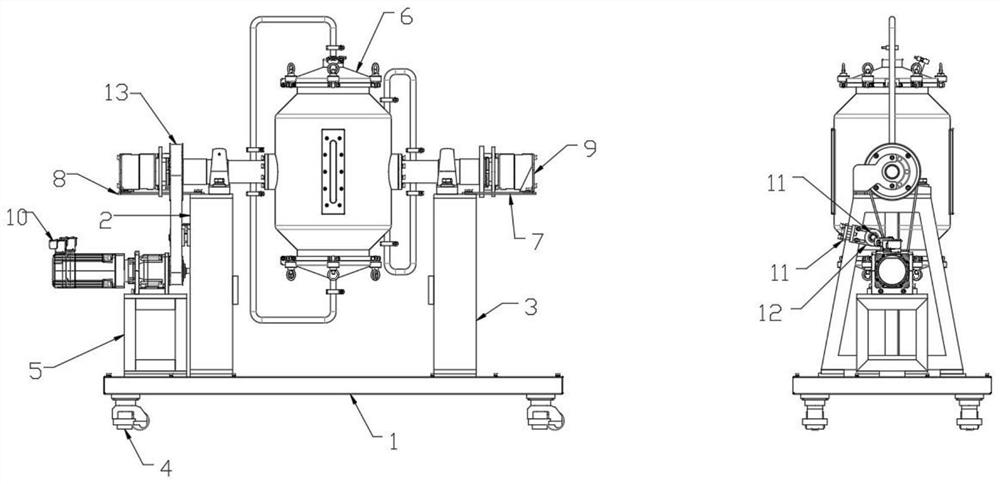

[0026] figure 1 It is a structural schematic diagram of the DNA / RNA industrial type automatic synthesizer in a kind of DNA / RNA industrial type automatic synthesizer of the present invention;

[0027] figure 2 It is a structural schematic diagram of the DNA / RNA industrial type automatic synthesizer in a kind of DNA / RNA industrial type automatic synthesizer of the present invention;

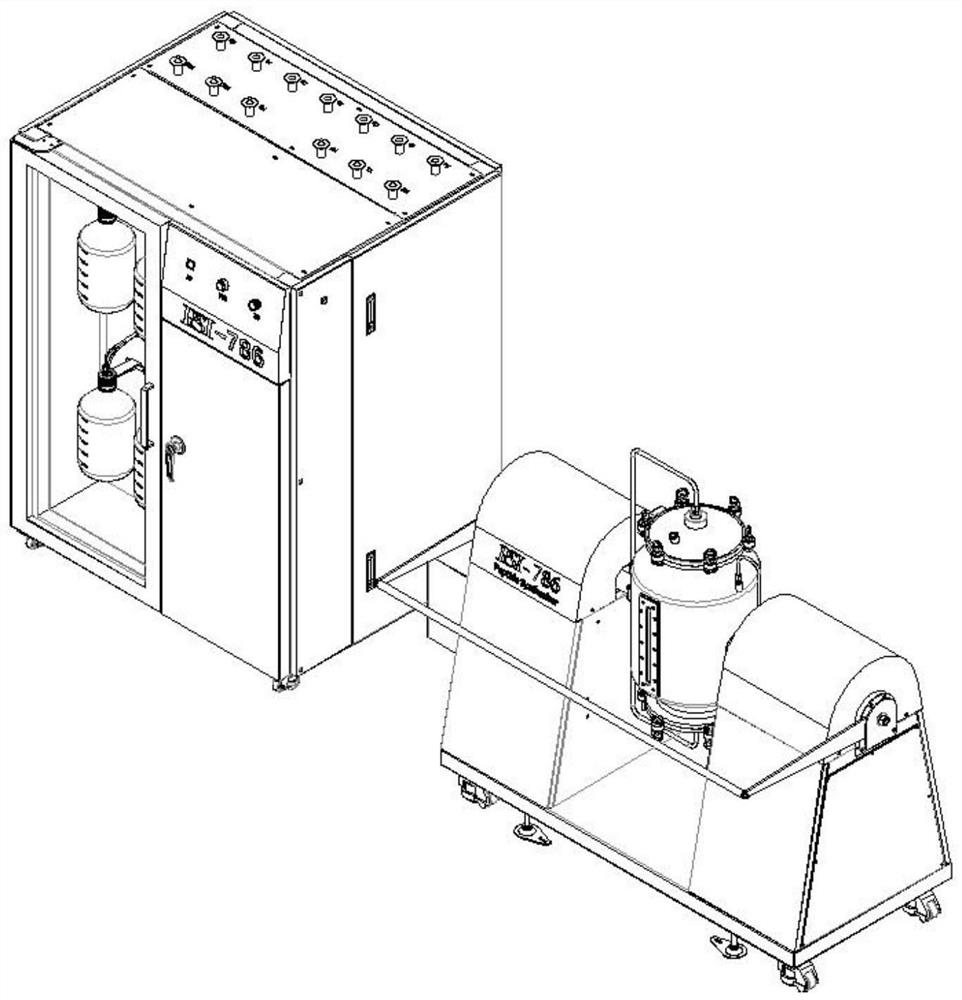

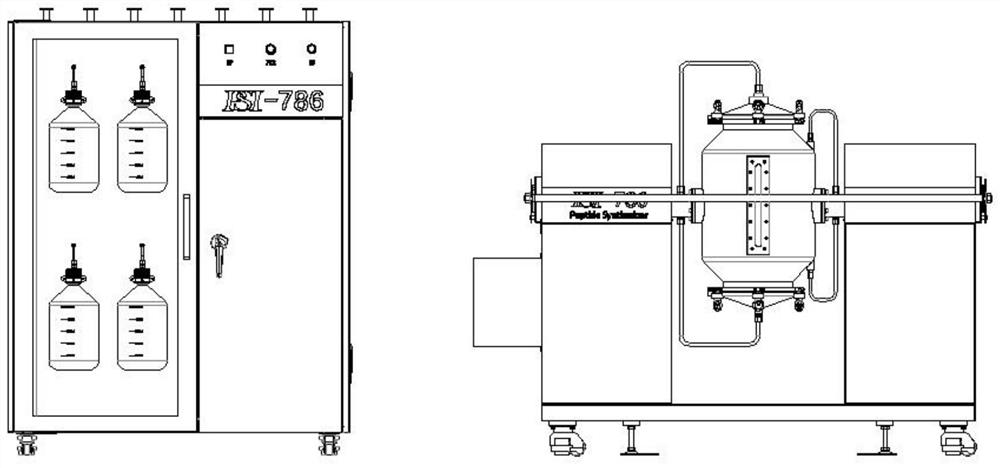

[0028] image 3 It is a schematic diagram of the appearance and structure of the host machine in a DNA / RNA industrial type automatic synthesizer of the present invention;

[0029] Figure 4 It is a schematic diagram of the reactor structure in a DNA / RNA industrial type automatic synthesizer of the present invention;

[0030] Figure 5 It is a structural schematic diagram of a valve cabinet in a DNA / RNA industrial automatic synthesizer of the present invention.

[0031] The present application will be further introduced below in conjunction with the embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com