System and method for controlling density of loose body of optical fiber preform in production process

An optical fiber preform and production process technology, applied in the field of optical fiber production, can solve the problems of not being able to find the density in time and changing the formula in time, unable to control the density uniformity of the rod body, unable to find the exact time point for formula adjustment, etc. Bad condition, increase strength, reduce cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

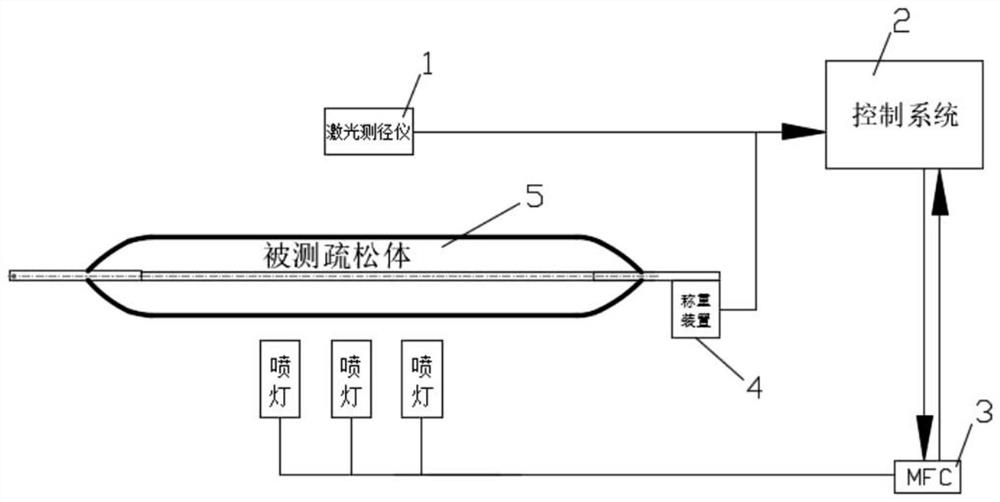

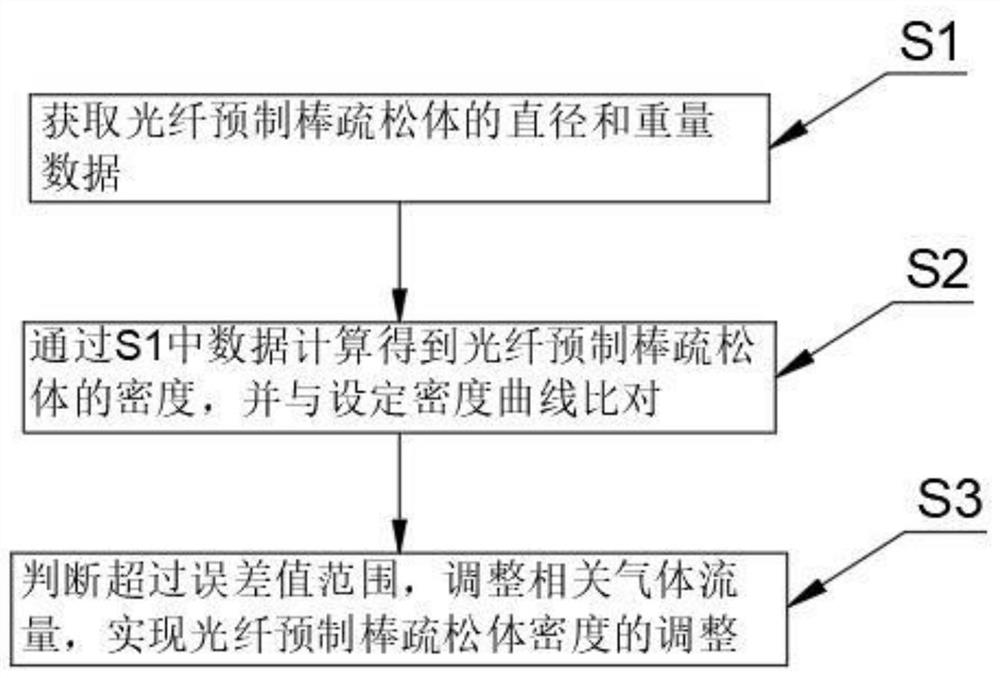

[0040] refer to figure 1 As shown, this embodiment provides a system for controlling the bulk density of optical fiber preforms in the production process, including

[0041] A monitoring system, used to monitor the diameter and weight of the fiber preform loose body 5, and to feed back the monitoring data in real time;

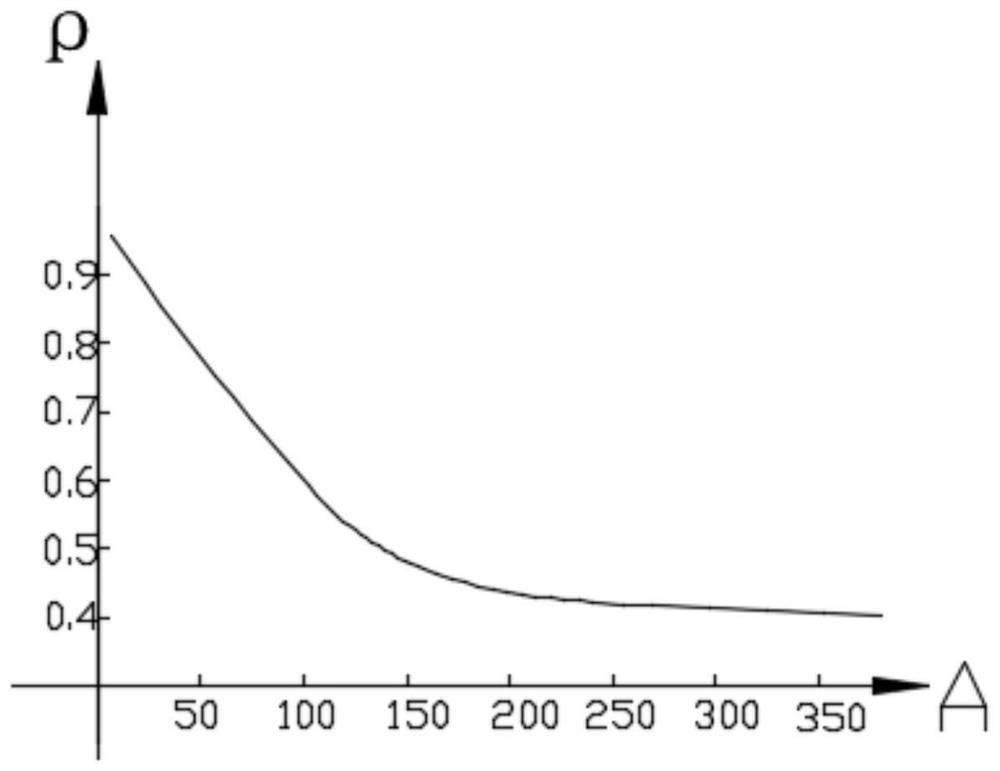

[0042] The control system 2 is used to receive the monitoring data, and calculate the density of the soot body 5 of the optical fiber preform based on it, and send a formula adjustment instruction after comparing with the set density curve to further obtain the density error;

[0043] The MFC3 is used to execute the recipe adjustment command issued by the control system 2, and control the blowtorch to adjust the related gas flow, thereby realizing the adjustment of the density of the optical fiber preform loose body 5.

[0044] The monitoring system of this embodiment includes a laser caliper 1 and a weighing device 4; wherein the laser caliper 1 is used to m...

Embodiment 2

[0048] In terms of specific implementation, this embodiment provides a specific implementation of a system for controlling the density of the soot body of the optical fiber preform in the production process. First, the density of the soot body is calculated according to the system, and compared with the set density curve, the density error How much, and then adjust the formula.

[0049] In this embodiment, what the laser caliper 1 tests is the distance from the laser caliper to the measured object, and the radius of the loose body is calculated according to the distance:

[0050] R=r+h1-h2 where r is the radius of the mandrel, h1 is the distance from the initial laser caliper to the mandrel, and h2 is the distance from the laser caliper to the loose body during testing.

[0051] In this embodiment, r is 15mm, h1 is 500mm, and h2 is 470mm, then the radius of the loose body is calculated as R, and R=17+500-470=45mm.

[0052] Calculate the volume of a loose body from its radius:...

Embodiment 3

[0062] The present embodiment provides a kind of optimum state of deposition, that is, when deposition reaches 100 times, the volume V of the loose body=19500cm 3 , where the weight of the loose body G = 12500g, density ρ = 0.641g / cm 3 , the set value is 0.6g / cm 3 , deviation 0.041g / cm 3 , adjust CH 4 After flow, the density becomes 0.605g / cm 3 , which meets the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com