Dry-wet combined production process for superhard material abrasive material

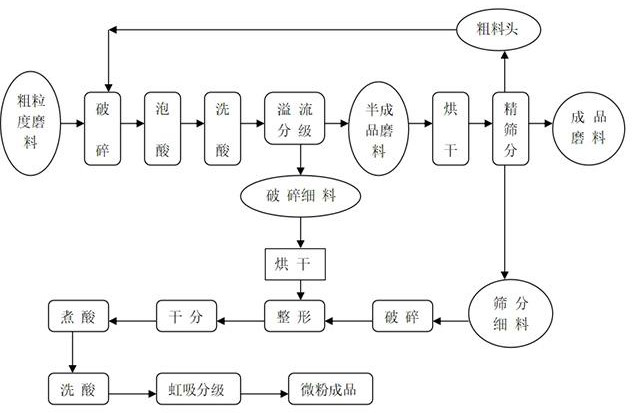

A dry-wet combination, production process technology, applied in other chemical processes, grain processing, chemical instruments and methods, etc., can solve the problems of lack of production of superhard material micropowder, waste of available abrasives, single production mode, etc., to improve revenue , the high degree of mechanization, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

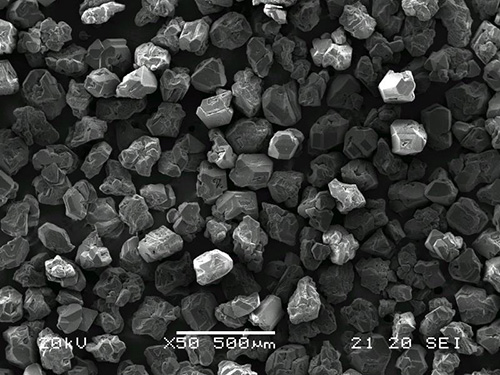

[0037] Preparation of finished abrasives:

[0038] (1) Take diamond particles with a particle size of not less than 270 mesh as raw materials, and use a jet mill for crushing treatment with a crushing pressure of 0.4 MPa. After processing to 170 mesh, the sieve rate is not less than 95%, and a mixture is obtained.

[0039] (2) Put the mixture obtained in step (1) into a hydrochloric acid solution with a concentration of 30%, soak it while stirring, and filter it after 2 hours, take the filter residue, and wash the filter residue with water several times until the last cleaning. Wastewater pH ≥ 7.0, to obtain pickling materials.

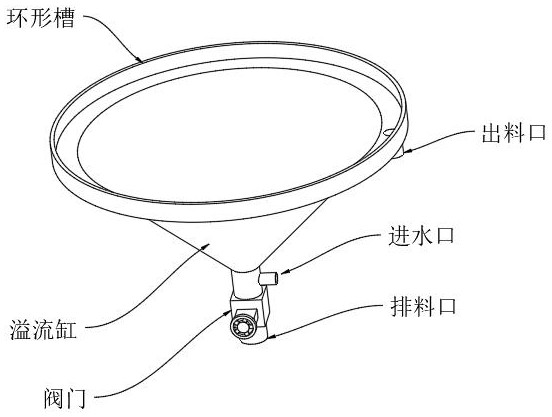

[0040] (3) use figure 2 The overflow device shown separates the pickling material obtained in step (2) according to the particle size, such as figure 2 As shown, the bottom of the overflow tank is provided with a discharge port and a water inlet, and a valve is provided at the discharge port, and an overflow tank is provided on the top of the over...

Embodiment 2

[0051] Preparation of finished abrasives:

[0052] (1) Cubic boron nitride particles with a particle size of not less than 270 mesh are used as raw materials, and crushed by a jet mill with a crushing pressure of 0.5 MPa, and the sieve rate of 170 mesh is not lower than 95% to obtain a mixture.

[0053] (2) Put the mixture obtained in step (1) into a hydrochloric acid solution with a concentration of 36%, soak it while stirring, and filter it after 1 hour, take the filter residue, and wash the filter residue with water several times until the last wash. Wastewater pH ≥ 7.0, to obtain pickling material.

[0054] (3) use figure 2 The overflow device shown separates the pickling material obtained in step (2) according to the particle size, such as figure 2 As shown, the bottom of the overflow tank is provided with a discharge port and a water inlet, and a valve is provided at the discharge port, and an overflow tank is provided on the top of the overflow tank, and the overflo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com