Drying machine suitable for powder mixing and drying method of drying machine

A drying machine and powder technology, applied in non-progressive drying machines, dryers, drying solid materials, etc., can solve the problems of slow mixing speed, slow heating and temperature rise, etc., achieve high mixing efficiency, good drying effect, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

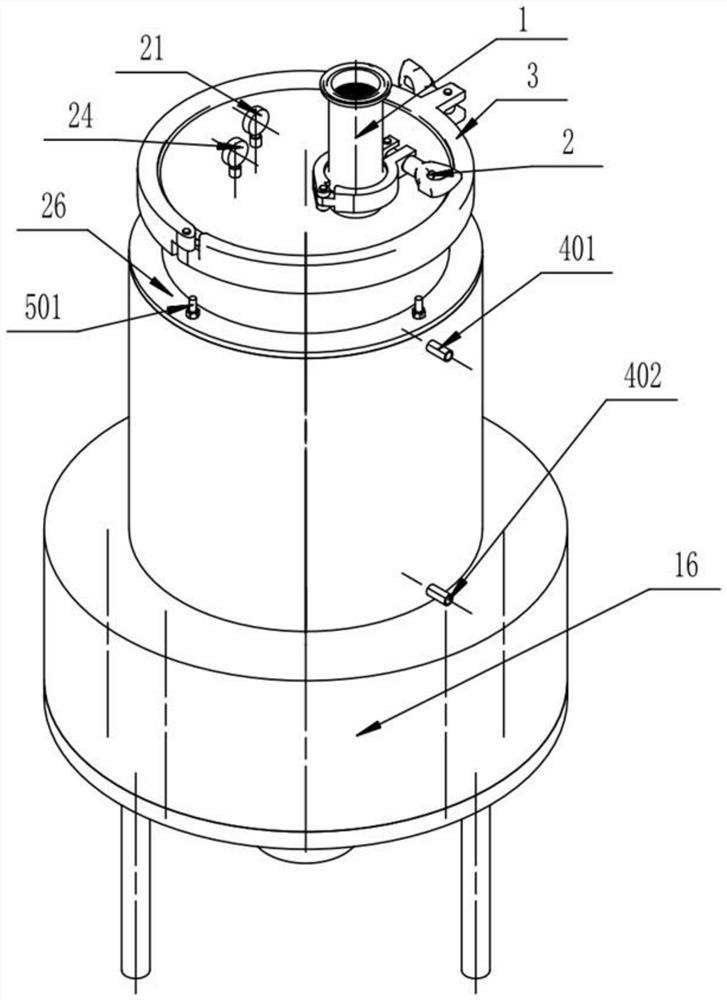

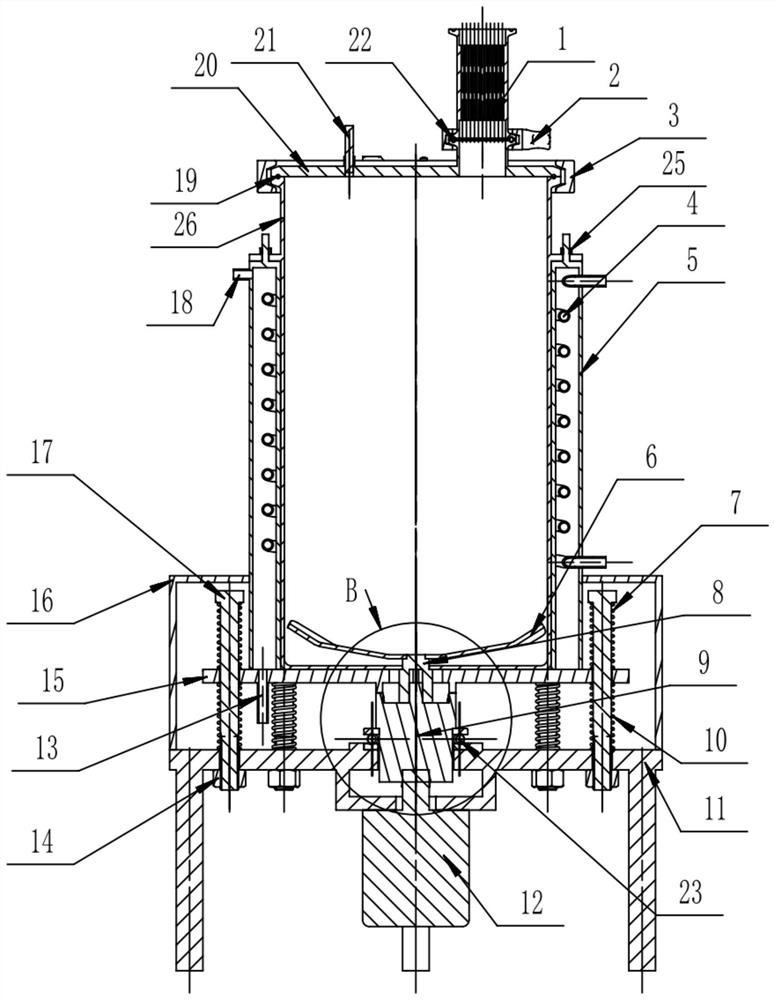

[0045] This embodiment provides a dryer suitable for powder mixing and its drying method, such as figure 1 and figure 2 As shown, it includes a base 11, a drying barrel 26, a stirring blade 6, a driving motor 12 and a vibrating mechanism. The legs of the base 11 are installed and fixed on the floor of the production workshop, and the table top of the base 11 is circular or square. The vibration mechanism includes a vibration platform 15 and an impact hammer 9 .

[0046] The vibrating platform 15 is erected above the table top of the base 11 , and the drying barrel 26 is installed on the upper surface of the vibrating platform 15 . The drying barrel 26 is a hollow body without a cover, and a through hole is provided at the bottom thereof. The stirring blade 6 is installed in the drying barrel 26 .

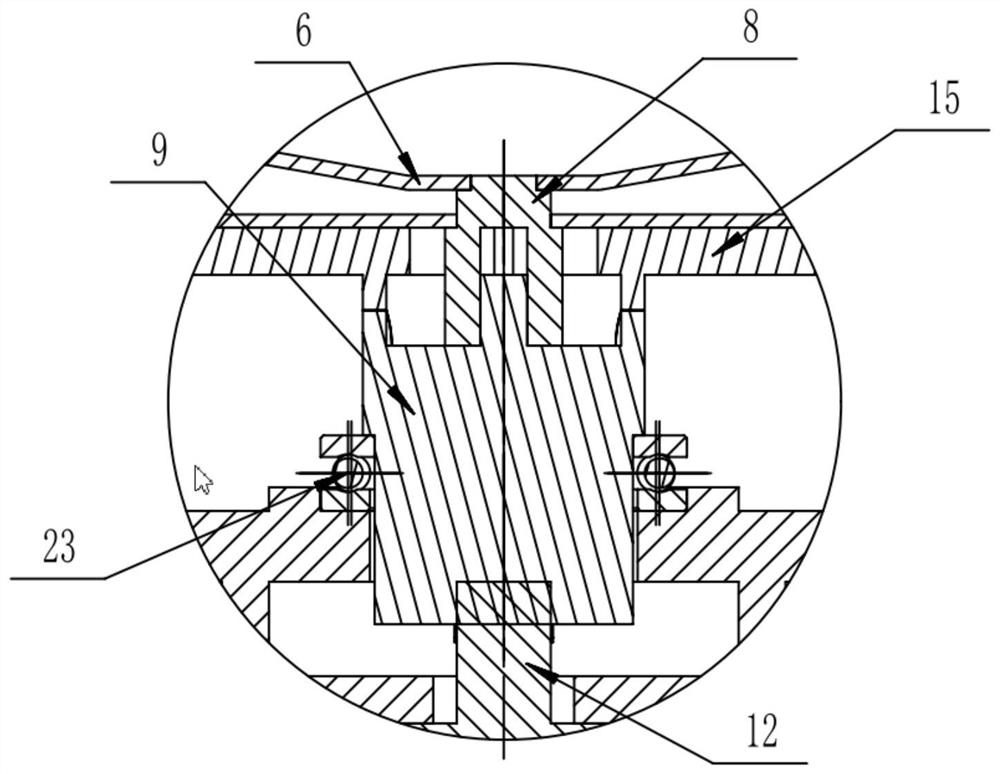

[0047] The impact hammer 9 is rotatably installed in the central hole on the base 11 through the first thrust bearing 23 . Such as Figure 8 As shown, the top of the impact h...

Embodiment 2

[0051] This embodiment provides a drying machine suitable for powder mixing and a drying method thereof, the basic structure of which is the same as that of Embodiment 1, such as figure 2 As shown, the base 11 is provided with a plurality of threaded holes, and the vibrating platform 15 is provided with second mounting holes 1501 having the same number as the threaded holes, and the positions of the threaded holes correspond to the positions of the second mounting holes 1501 . And the lower end surface of the vibrating platform 15 is provided with a discharge port 13 .

[0052] The threaded hole is threadedly matched with the first screw 17 , the threaded portion of the first screw 17 is assembled with the second nut 14 , and fixed on the base 11 by the second nut 14 , and the second nut 14 is located on the lower surface of the base 11 .

[0053] The length of the first screw 17 is greater than the height between the vibration platform 15 and the base 11 . The outer circumfer...

Embodiment 3

[0055] This embodiment provides a drying machine suitable for powder mixing and a drying method thereof, the basic structure of which is the same as that of Embodiment 2, such as figure 1 and figure 2 As shown, a heating tank 5 is also included, and the shape of the heating tank 5 matches the shape of the drying barrel 26 . The heating pot 5 is sleeved on the outer periphery of the drying barrel 26 and welded to the upper surface of the vibrating platform 15 , and the heating pot 5 is flanged to the drying barrel 26 .

[0056] The shape of the drying barrel 26 is circular, the shape of the heating tank 5 is circular, and the inner diameter of the ring of the heating tank 5 is the same as the outer diameter of the drying barrel 26 . Steam heating coil 4 is installed inside heating tank 5, and its shape is spiral. In order to enhance the heating effect, the steam heating coil 4 is coiled on the inner wall of the heating tank 5 . The side of the heating tank 5 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com