Preparation method of modified poplar veneer impregnated with graphene furfuryl alcohol resin

A poplar veneer, resin impregnation technology, applied in the direction of impregnated wood, wood impregnation, pressure impregnation, etc., can solve the problems of low density, lack of wood resources, loose material, etc., to improve dispersion, simple production process, sound insulation The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the technical solutions of the present invention are described in detail below with specific examples, but the present invention is not limited thereto.

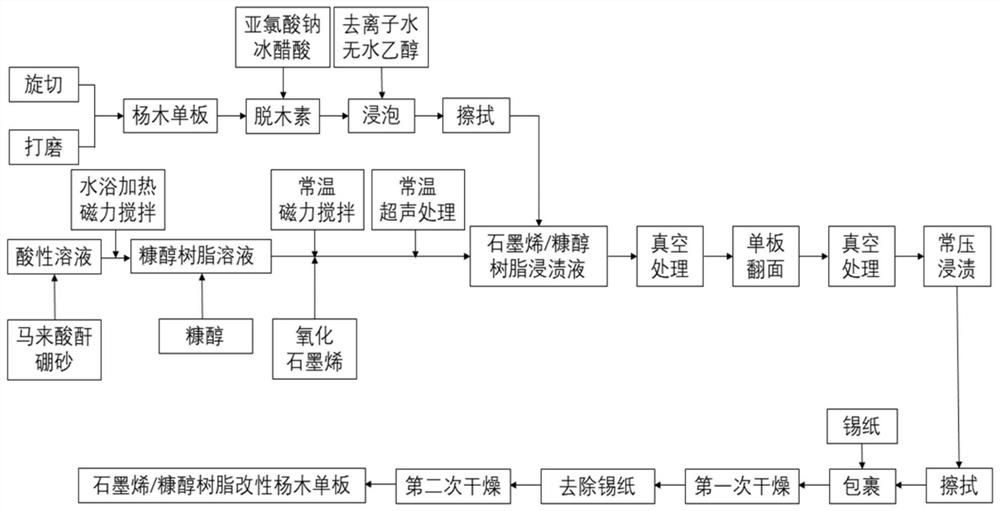

[0028] like figure 1 As shown, the preparation method of the graphene furfuryl alcohol resin impregnating modified poplar veneer for sound insulation, the steps include:

[0029] 1) Preparation, including delignification pretreatment of poplar veneer and preparation of graphene / furfuryl alcohol resin impregnation solution;

[0030] Poplar veneer delignification pretreatment: the poplar veneer in the present invention is a rotary cut material, the surface and edge burrs are removed, and the delignification is carried out by the sodium chlorite method (the mass fraction of sodium chlorite ranges from 5 to 6 %, add glacial acetic acid to adjust the pH value to within the range of 3~4), heat in a water bath at 86°C for 2.5h, soak in deionized water for 3~5 times, until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com