Self-compacting fair-faced concrete based on volcanic rock limestone powder and preparation method of self-compacting fair-faced concrete

A technology of fair-faced concrete and limestone powder, which is applied in the field of building materials, can solve the problems of high cost and poor performance of self-compacting fair-faced concrete, and achieve the effects of promoting resource utilization, reducing consumption, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

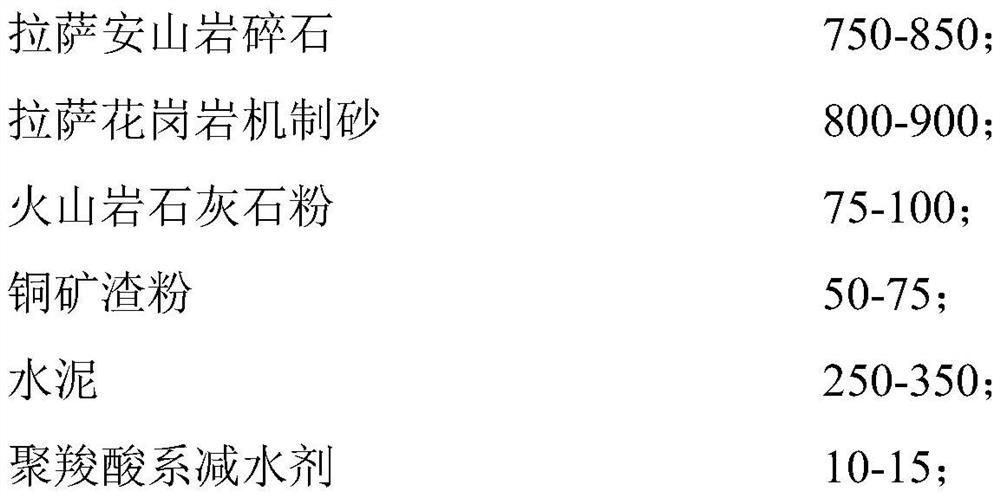

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the self-compacting concrete is as follows: first, pour the weighed Lhasa andesite crushed stone, Lhasa granite machine-made sand, volcanic limestone powder, copper slag powder and cement into the mixer, and stir for 3 minutes to mix the dry powder materials evenly. Then mix the water reducer and water and other liquids evenly, then pour them into the evenly mixed dry powder, and mechanically stir for 5 minutes to obtain self-compacting fair-faced concrete.

[0026] The Lhasa andesite gravel, Lhasa granite machine-made sand and Tibet volcanic andesite mentioned in this patent are all collected from the vicinity of Moga Volcano, Langba Village, Ma Town, Duilongdeqing District, Lhasa City, and are controlled by Shenghang Building Materials Group, a subsidiary of Lhasa Urban Construction Investment Management Co., Ltd. The enterprise—Tibet Wuyang Industrial Co., Ltd. is responsible for mining.

Embodiment 1

[0029] A self-compacting clear-water concrete based on volcanic limestone powder, the preparation method of which comprises: pouring 850kg of Lhasa andesite crushed stone, 800kg of Lhasa granite machine-made sand, 75kg of volcanic limestone powder, 50kg of copper slag powder, and 350kg of cement into a mixer, and dry mixing After 3 minutes, 15kg of water reducer and 190kg of water (water-binder ratio: 0.4) were mixed, and after 5 minutes of stirring by a forced mixer, the self-compacting fair-faced concrete was obtained.

[0030] Among them, the volcanic rock limestone powder has an ignition loss of 2.1% and a 28d activity index of 117%; the cement is 42.5 grade ordinary Portland cement, the water consumption of the standard consistency of the cement is 22%, and the 28d mortar strength of the cement is 54MPa; Lhasa The fineness modulus of granite machine-made sand is 2.7-3.0, the MB value is 1.2, the stone powder content is 2.4%, and the mud content is 0.4%; the average particl...

Embodiment 2

[0033] A self-compacting clear-water concrete based on volcanic limestone powder, the preparation method of which comprises: pouring 800kg of Lhasa andesite crushed stone, 850kg of Lhasa granite machine-made sand, 86kg of volcanic limestone powder, 60kg of copper slag powder, and 300kg of cement into a mixer, and dry mixing After 3 minutes, 12kg of water reducing agent and 169kg of water (water-binder ratio is 0.38) were mixed, and after 5 minutes of stirring by a forced mixer, the self-compacting fair-faced concrete was obtained.

[0034] The performance test was carried out by the same method as in Example 1, and the results showed that the concrete had good workability and no segregation or bleeding. The SF of the concrete mixture is 590mm, the T500 is 6s, the J-ring obstacle height difference is 14mm, the stability index L is 6mm, and the 28d compressive strength is 52MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com