Melanin separation and extraction method based on ionic liquid

A technology of ionic liquid and extraction method, which is applied in the field of waste hair recycling, can solve the problems of long pretreatment time, high price of protease, low yield of melanin recovery, etc., and achieve the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

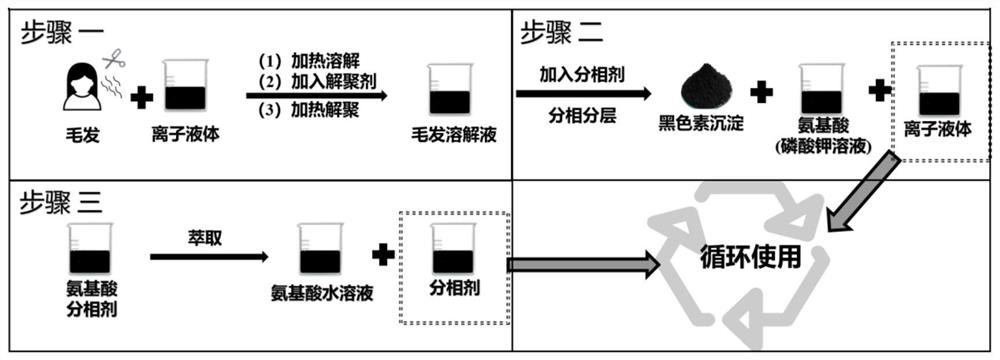

[0030] figure 1 It is the technological process flow of the targeted extraction of melanin based on ionic liquid in the present invention.

[0031] Step 1: A mixture of 0.2 g of washed discarded human hair (hair) and 4 g of 1-butyl-3-methylimidazolium chloride (ionic liquid) was heated in a beaker at 130° C. until the discarded human hair was completely dissolved. 0.2 mL of dilute sulfuric acid (50 wt %) (depolymerization agent) was added to the mixture, and the mixture was heated at 120° C. for 1.2 hours.

[0032] Step 2: Add 20mL of aqueous solution to the mixture, shake the mixture vigorously for 2min, and then use a centrifuge to centrifuge (5000rpm, 5min). After centrifugation, the precipitate is a melanin product with a yield of 6.02%. g / ml K 3 PO 4 (Phase separation agent) The upper phase and the lower phase are separated. The upper layer solution was rich in 1-butyl-3-methylimidazolium chloride salt, was collected, and was directly recycled to step 1 after 5 hours ...

Embodiment 2

[0035] Step 1: A mixture of 1 g of washed discarded brown wool (hair) and 20 g of 1-butyl-3-methylimidazolium chloride (ionic liquid) was heated in a beaker at 130° C. until the discarded human hair was completely dissolved. 1 mL of dilute sulfuric acid (50 wt %) (depolymerization agent) was added to the mixture, and the mixture was heated at 120° C. for 2.2 hours.

[0036] Step 2: Add 100mL of aqueous solution to the mixture, shake the mixture vigorously for 6min, and then use a centrifuge to centrifuge (5000rpm, 10min). After centrifugation, the precipitate is a melanin product with a yield of 7.24%. g / ml K 3 PO 4 (Phase-separating agent) The upper phase and the lower phase are separated. The upper layer solution was rich in 1-butyl-3-methylimidazolium chloride salt, was collected, and was directly recycled to step 1 after 5 hours of vacuum distillation. The lower layer solution is rich in compound amino acids and phase-splitting agent, and the lower phase rich in compound ...

Embodiment 3

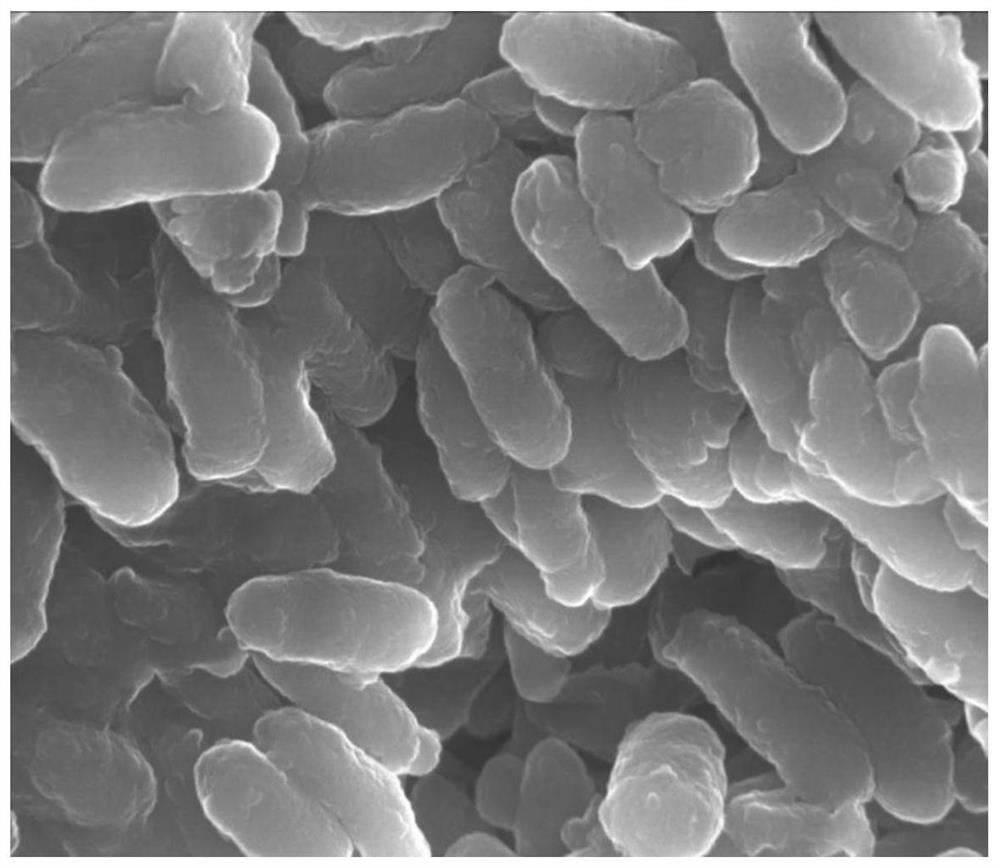

[0039] Carry out SEM test on the basis of embodiment 1, test result sees figure 2 .

[0040] Test description: Usually, it is possible to directly observe whether the surface morphology of melanin remains in the original nano-particle shape through SEM testing, so as to judge whether the natural morphology of melanin is destroyed. It is generally considered that granular melanin that maintains its natural shape is an excellent melanin product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com