Resistance paste with low temperature coefficient

A low temperature coefficient, resistance paste technology, applied in the direction of resistors, resistance manufacturing, circuits, etc., can solve the problems of large changes in the resistance value of resistors, the inability to apply high-precision resistors, and large differences in the temperature coefficient of resistance. Achieve the effect of small positive and negative temperature coefficient difference, meet product performance requirements, and solve large temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

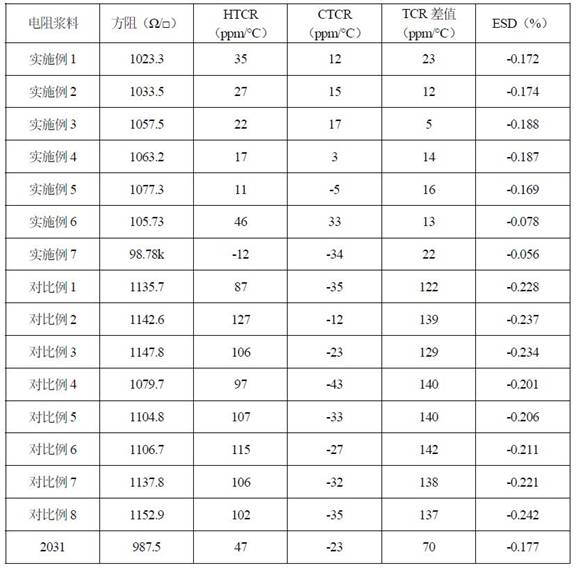

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, it does not play a role in defining the scope of the present invention. The scope of the present invention is defined only by the claims, any omitted skilled artisan on the basis of the disclosed embodiment of the present invention made, substitutions or modifications are intended to fall within the scope of the present invention.

[0015] 1, selected conductive powder: specific surface area of ruthenium dioxide 25 ~ 55m 2 / G, a specific surface area of lead ruthenate 3 ~ 10m 2 / g.

[0016] Preparation of 2, a lead borosilicate glass frit: a mass percentage PbO 65%, SiO 2 3%, CaCO 3 9%, Al 2 O 3 3%, B 2 O 3 After 15%, ZnO 5% starting material was weighed, various raw materials were mixed uniformly, the resulting mixture was placed in a melting furnace for melting 1050 deg.] C, holding time 2h, the resulting solution was subjected to water quenching gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com