Catalytic material with hydrogenation performance and preparation method and application thereof

A catalytic material and performance technology, applied in the direction of catalyst carriers, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of high cost, cumbersome waste catalyst treatment and reuse steps, and hindered catalyst activity and other issues to achieve the effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Carrier preparation

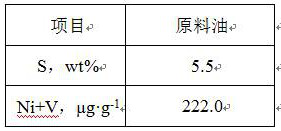

[0047] Grind 1000g of petroleum coke into powder, then mix it evenly with 50g of calcium carbonate and 3000g of potassium carbonate, put it in a tube furnace, start to heat up, when the temperature exceeds 100°C, feed water vapor, and the space velocity is 50h -1 , continue to raise the temperature to 700°C, keep it constant for 60 minutes, then raise the temperature to 900°C, keep it constant for 60 minutes, stop feeding water vapor, and drop to room temperature under vacuum conditions, the vacuum degree is -0.1MPa.

[0048] Grind the above-mentioned activated sample into powder, mix it with a hydrochloric acid solution with a concentration of 20wt% at a volume ratio of 1:3, stir thoroughly, the mixing time is 8h, and then perform solid-liquid separation, and the obtained solid is washed with deionized water , until the pH value of the filtrate was neutral, the obtained fixed sample was placed in a vacuum drying oven, and dried at 150° C. for ...

Embodiment 2

[0055] (1) Carrier preparation

[0056] Grind 1000g of petroleum coke into powder, then mix it evenly with 100g of calcium carbonate and 4000g of potassium carbonate, put it in a tube furnace, start to heat up, when the temperature exceeds 100°C, feed water vapor, and the space velocity is 50h -1 , continue to raise the temperature to 700°C, keep it constant for 60 minutes, then raise the temperature to 900°C, keep it constant for 60 minutes, stop feeding water vapor, and drop to room temperature under vacuum conditions, the vacuum degree is -0.1MPa.

[0057] Grind the above-mentioned activated sample into powder, mix it with a hydrochloric acid solution with a concentration of 20wt% at a volume ratio of 1:3, stir thoroughly, the mixing time is 8h, and then perform solid-liquid separation, and the obtained solid is washed with deionized water , until the pH value of the filtrate was neutral, the obtained fixed sample was placed in a vacuum drying oven, and dried at 150° C. for...

Embodiment 3

[0064] (1) Carrier preparation

[0065] Grind 1000g of petroleum coke into powder, then mix it evenly with 150g of calcium carbonate and 5000g of potassium carbonate, place it in a tube furnace, start to heat up, when the temperature exceeds 100°C, inject water vapor, and the space velocity is 50h -1 , continue to raise the temperature to 700°C, keep it constant for 60 minutes, then raise the temperature to 900°C, keep it constant for 60 minutes, stop feeding water vapor, and drop to room temperature under vacuum conditions, the vacuum degree is -0.1MPa.

[0066] Grind the above-mentioned activated sample into powder, mix it with a hydrochloric acid solution with a concentration of 20wt% at a volume ratio of 1:3, stir thoroughly, the mixing time is 8h, and then perform solid-liquid separation, and the obtained solid is washed with deionized water , until the pH value of the filtrate was neutral, the obtained fixed sample was placed in a vacuum drying oven, and dried at 150° C....

PUM

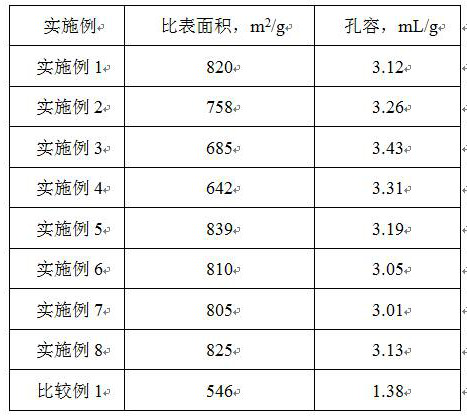

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com