A new environmental protection electrostatic precipitator and its application

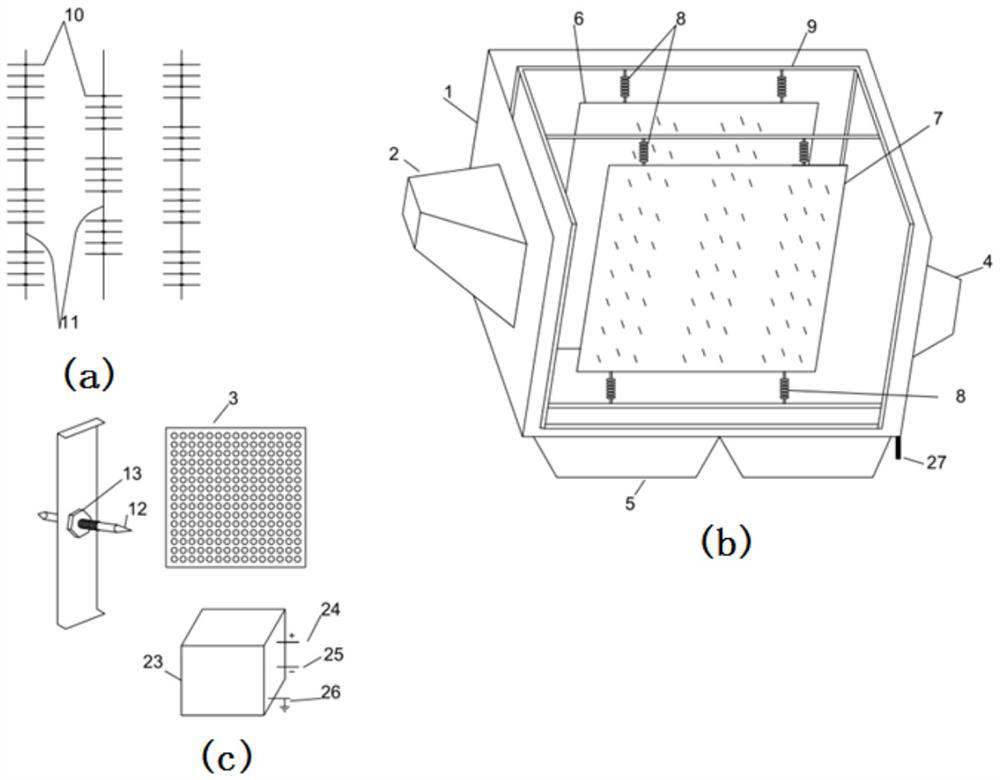

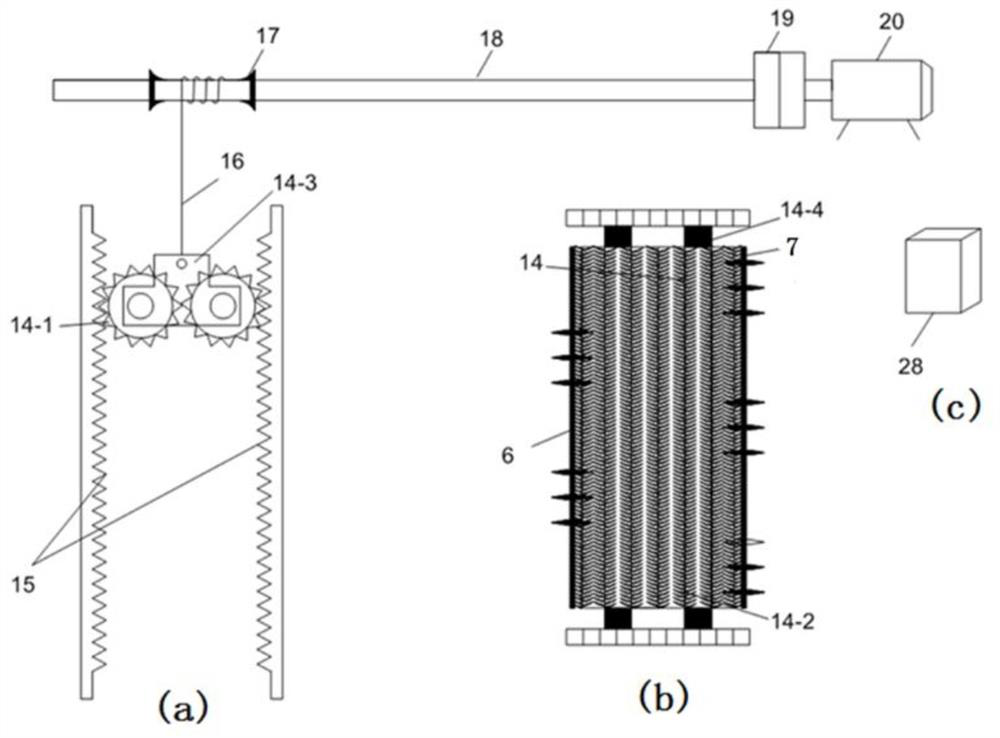

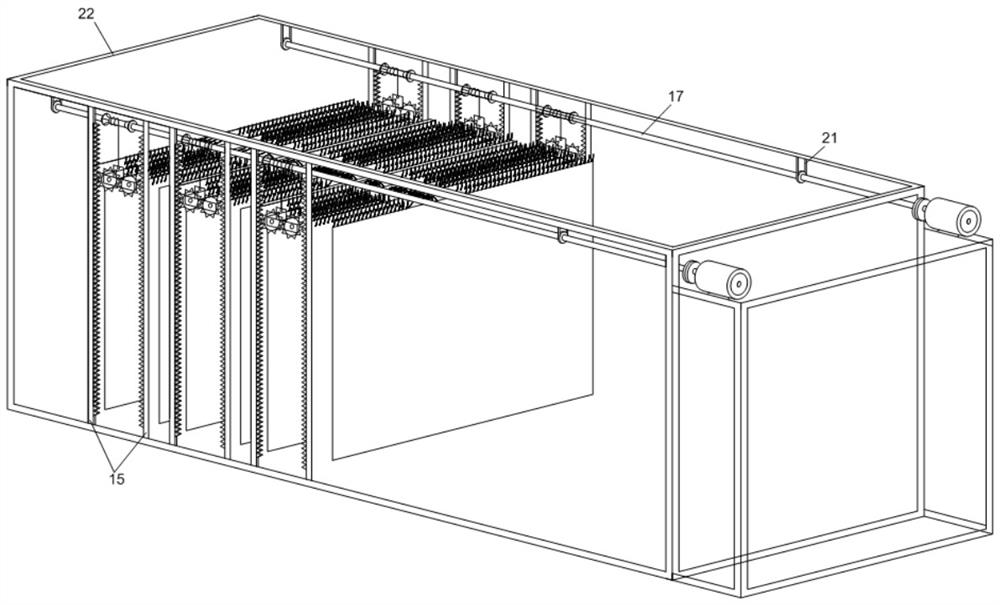

An electrostatic precipitator and precipitator technology, which is applied in the field of brush roller dust removal electrostatic precipitator and dual power supply discharge and dust collector integrated pole plate, can solve the problem of not being able to increase the dust collection capacity, and achieve the reduction of secondary dust, The effect of convenient maintenance and accelerated adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] Experiment A: First, the existing structure of the dust collector is used for the test. The volume width is 3m, the length is 10m, and the height is 6m. The electric field of the dust collector is formed by the cathode of the discharge prickly wire and the anode of the dust collection plate, and the distance between the different poles is 220mm. ;The power supply adopts a single-phase negative output high-frequency soft and stable power supply. The wiring method is: the high-voltage output end of the power supply is connected to the discharge electrode needle-type cathode line; the other end of the power supply is connected to the dust collection plate, and the dust collection plate is grounded together with the dust collector shell. . The data after electrification is: voltage 83kv, current 60mA. The flue gas volume is 30,000 m3 / h, and the inlet concentration is 3g / m3. After treatment, the emission concentration is 57mg / m3.

[0057] Experiment B: Under the condition ...

example 2

[0068] Experiment A: First, the existing dust collector structure is used for the test. The volume width is 3m, the length is 10m, and the height is 6m. The electric field of the dust collector is formed by the cathode of the discharge prickly wire and the anode of the dust collection plate, and the distance between the different poles is 400mm. ;The power supply adopts a single-phase negative output high-frequency soft and stable power supply, and the wiring method is: the high-voltage output end of the power supply is connected to the needle-type cathode line of the discharge electrode; . The data after electrification is: voltage 130kv, current 80mA. The flue gas volume is 30,000 m3 / h, and the inlet concentration is 3g / m3. After treatment, the emission concentration is 50mg / m3.

[0069] Experiment B: Under the condition that the volume width of the precipitator is 3m, the length is 10m, and the height is 6m, the new environmental protection electrostatic precipitator tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com