Preparation method of monofilament with adsorption function

A monofilament and functional technology, applied in the field of preparation of monofilaments with adsorption function, can solve the problems of inability to guarantee wear resistance and peel resistance, and reduce the effective adsorption capacity of activated carbon, and achieve improved binding force, high adsorption function, combined with solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

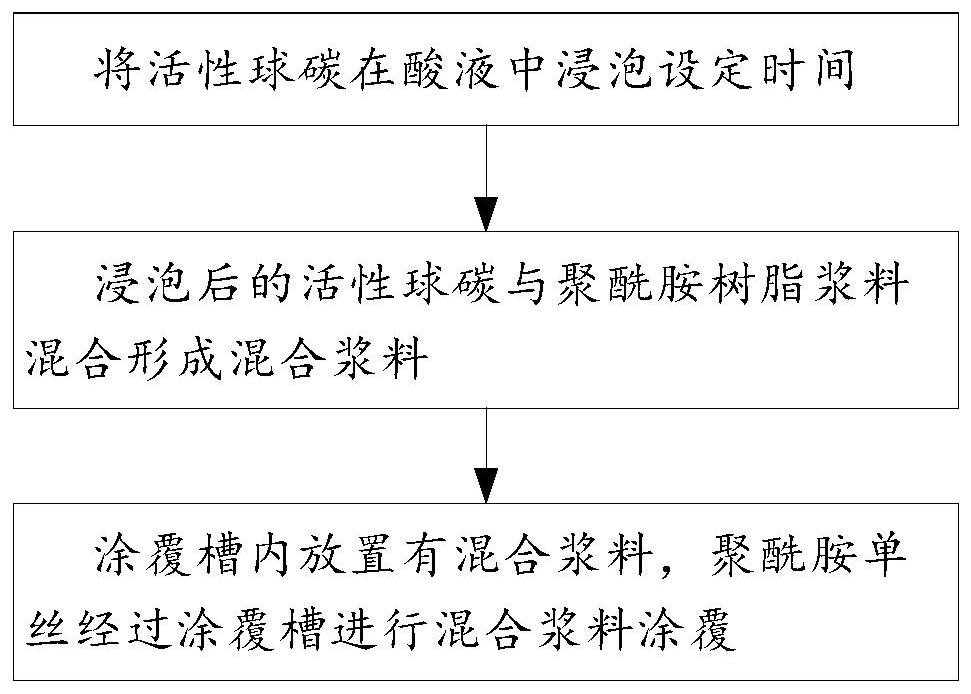

[0016] Please refer to figure 1 , the present embodiment provides a method for preparing a monofilament with adsorption function, which is characterized in that it includes:

[0017] Soak the activated spherical carbon in the acid solution for a set time;

[0018] The activated spherical carbon after soaking is mixed with polyamide resin slurry to form a mixed slurry, and the polyamide resin slurry is composed of the following components by mass: 50-60 parts of formic acid, 29-45 parts of acetic acid, 5-8 parts Polyamide resin, 0.9-1.2 parts of titanate coupling agent, 0.4-0.6 parts of fumed silica, 1.3-1.5 parts of propylene glycol phenyl ether;

[0019] The mixed slurry is placed in the coating tank, and the polyamide monofilament or polyamide multifilament passes through the coating tank to be coated with the mixed slurry.

[0020] Among them, by soaking the activated spherical carbon in the acid solution, acid treatment is carried out on the activated spherical carbon, w...

no. 1 example

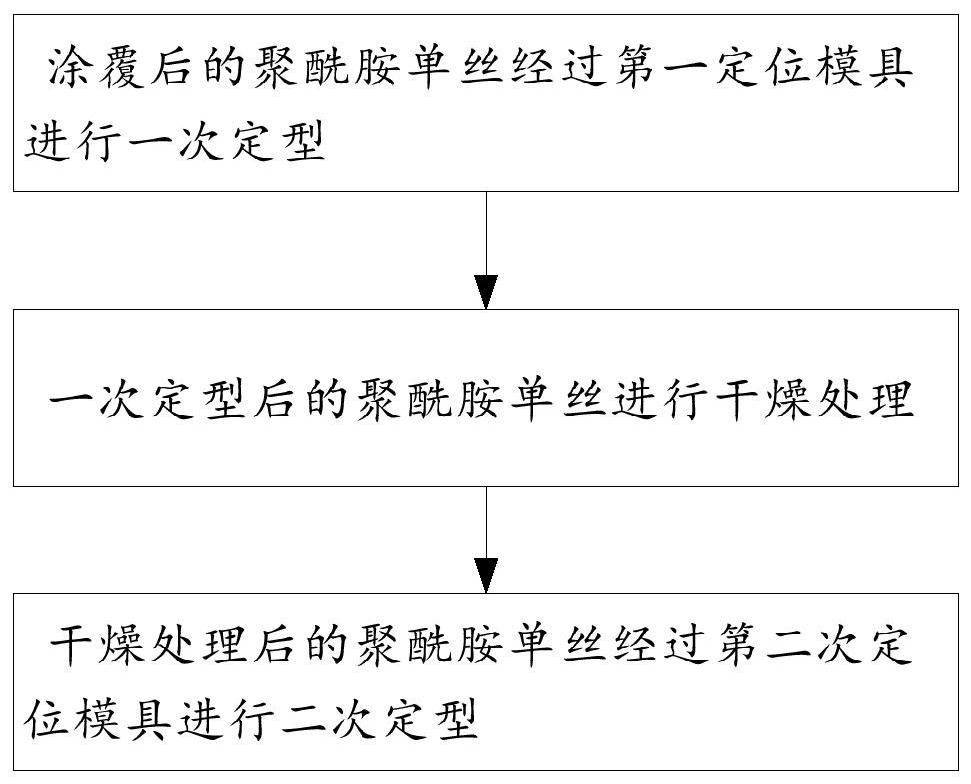

[0037] The particle size is 30 μm spherical activated carbon soaked in formic acid for 12h, then it is mixed acid (formic acid mass fraction 50, acetic acid mass fraction 42), polyamide resin (mass fraction is 5), titanate coupling agent (mass fraction The number of parts is 1.0), fumed silica (0.5 parts by mass), and propylene glycol phenyl ether (1.5 parts by mass) to form a mixed slurry, which is stirred evenly and then statically defoamed. Pass the polyamide monofilament with a diameter of 0.8mm through the coating tank, pass through the positioning mold and the diameter-controlling mold successively, the diameter of the die mouth is 0.9mm, dry in an oven at 150°C, and pass through the second shaping of the mold mouth with a diameter of 0.85mm , to obtain a high-efficiency adsorption monofilament with a diameter of 0.85mm, and the polyamide monofilament has a wire-feeding speed of 15m / min.

[0038] The ultimate monofilament with adsorption function has a breaking strength ...

no. 2 example

[0040]The particle size is 30 μm spherical activated carbon soaked in formic acid for 24h, then it is mixed acid (formic acid mass fraction 60, acetic acid mass fraction 29), polyamide resin (mass fraction is 8), titanate coupling agent (mass fraction The number of parts is 1.0), fumed silica (0.5 parts by mass), and propylene glycol phenyl ether (1.5 parts by mass) to form a mixed slurry, which is stirred evenly and then statically defoamed. Pass the polyamide monofilament with a diameter of 0.8mm through the coating tank, pass through the positioning mold and the diameter-controlling mold successively, the diameter of the die mouth is 0.9mm, dry in an oven at 120°C, and pass through the mold mouth with a diameter of 0.85mm for secondary shaping , to obtain a high-efficiency adsorption monofilament with a diameter of 0.85mm, and the polyamide monofilament has a wire-feeding speed of 15m / min.

[0041] The breaking strength of the adsorption monofilament is 5.43cN / dtex, which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com