Verification method of turbine disc part machining process

A technology of parts processing and verification method, applied in the direction of geometric CAD, design optimization/simulation, special data processing application, etc., can solve the problems of unrealistic blank test, high test cost, expensive processing cost, etc., to reduce test cost and ensure Feasibility, effect of saving material and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

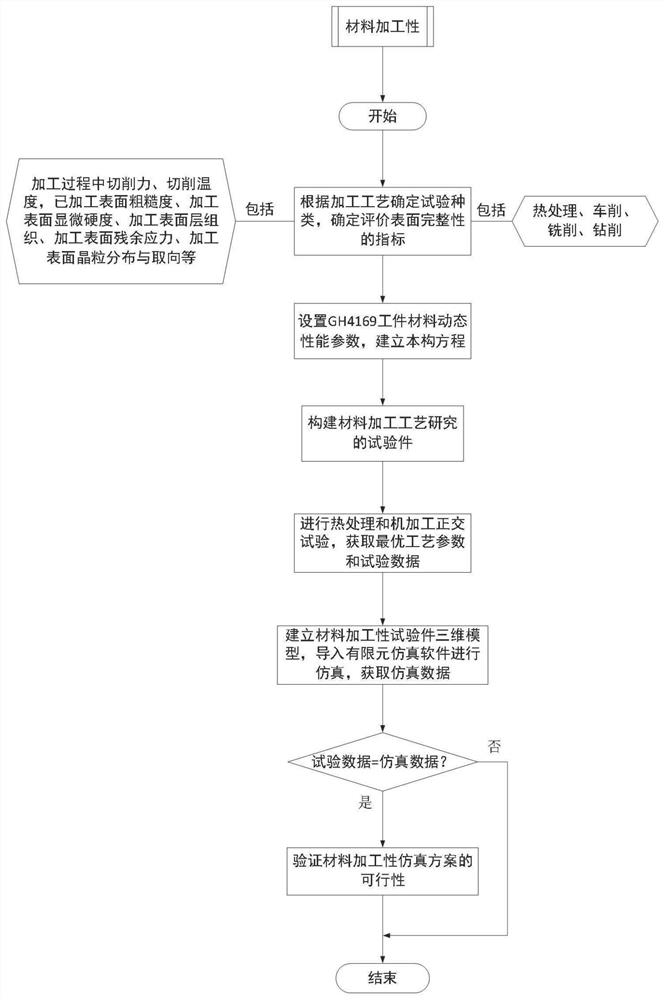

[0052] In a typical embodiment of the present invention, such as Figure 1-15 As shown, a verification method for the machining process of turbine disc parts is proposed, including the following steps:

[0053] The verification methods of processing technology are divided into three levels: material processability verification, feature processability verification and part processability verification.

[0054] Among them, the first level is the material processability verification, which includes a large number of physical tests and appropriate simulation verification, to study the processing performance of the turbine disk material and the integrity of the processed surface, to establish a simulation program for the study of material processability and to verify its feasibility Performance evaluation indicators mainly include cutting force during cutting, cutting temperature and roughness of machined surface, microhardness of machined surface, microstructure of machined surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com