Low-frequency sound absorption covering layer containing cylindrical scatterers with parameters changing in gradient mode

A technology of sound-absorbing covering layer and gradient change, which is applied in the direction of sound-emitting devices, layered products, and metal-layered products. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

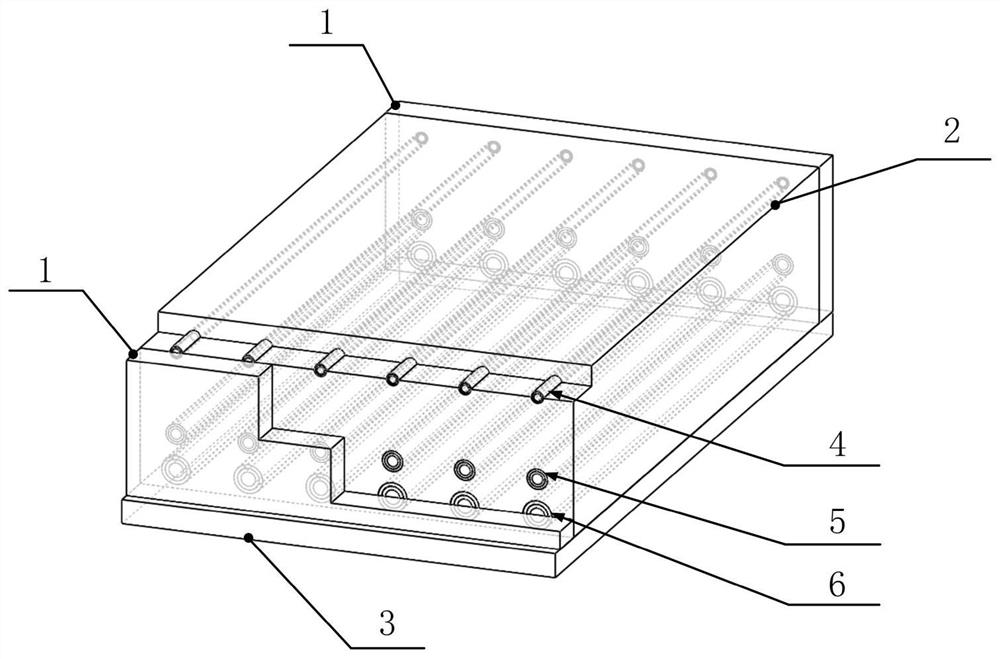

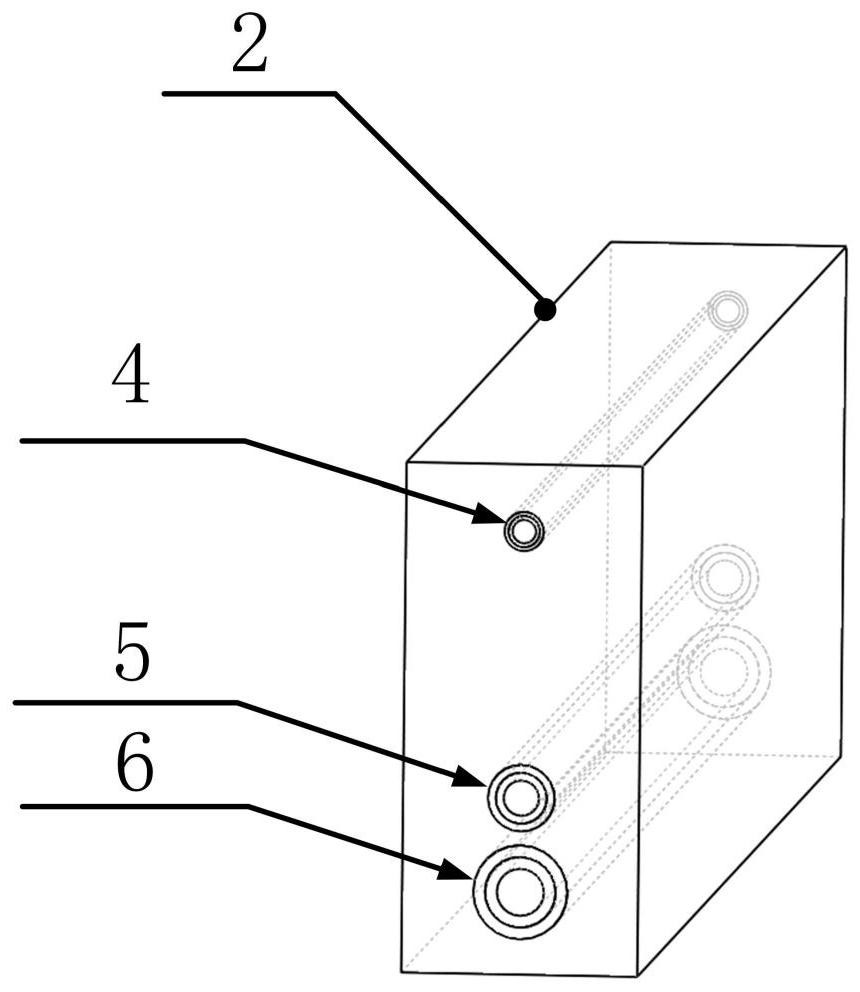

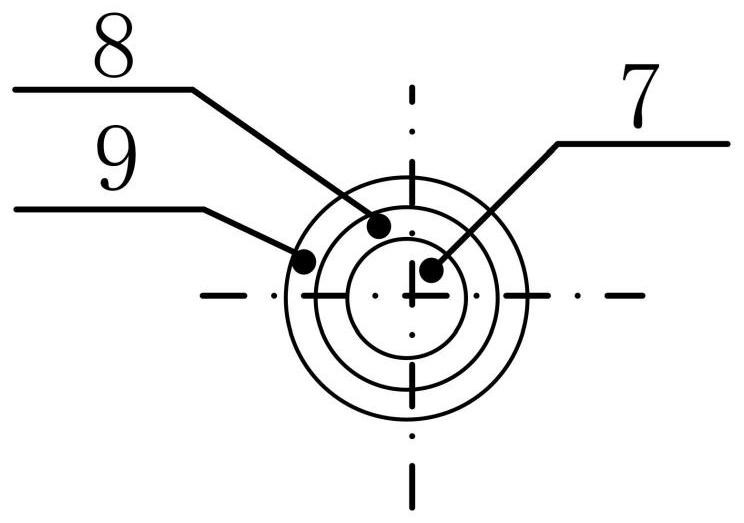

[0029] The material of the sound-absorbing layer and the sealing layer in the sound-absorbing cover layer of the present invention is a kind of PDMS silicone rubber, and the density of the PDMS silicone rubber is 1000kg / m 3 , the complex Young's modulus is (1.879+0.540i) MPa, and Poisson's ratio is 0.4997. The density of the base layer is 7890kg / m 3 , Young's modulus is 210GPa, Poisson's ratio is 0.3. Three layers of cylindrical cavities are distributed in the sound-absorbing covering.

[0030] In the present invention, the low-frequency sound-absorbing covering layer containing a cylindrical scatterer with a parameter changing in gradient, the sound-absorbing covering layer containing a cylindrical cavity with a parameter changing in a gradient, and the low-frequency sound-absorbing covering layer containing a cylindrical scatterer with a parameter changing in a negative gradient comparing. For the sound-absorbing covering layer of the present invention containing cylindri...

Embodiment 2

[0033] The material of the sound-absorbing layer and the sealing layer in the sound-absorbing covering layer of this example is a kind of PDMS silicone rubber, and the density of PDMS silicone rubber is 1000kg / m 3 , the complex Young's modulus is (1.879+0.540i) MPa, and Poisson's ratio is 0.4997. The density of the base layer is 7890kg / m 3 , Young's modulus is 210GPa, Poisson's ratio is 0.3. Three layers of cylindrical diffusers are distributed in the sound-absorbing covering.

[0034] Compared with the present invention, the sound-absorbing covering layer with the thickness of the cladding layer in two cylindrical scatterers having a different distribution from the sound-absorbing covering layer containing the cylindrical scatterer whose parameters change in gradients in the present invention is used for comparison. For the sound-absorbing coating of the present invention that contains cylindrical scatterers whose parameters vary in gradient: in each unit, the first layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com