Synchronous rectification control circuit

A technology of synchronous rectification and control circuit, which is applied in the direction of control/adjustment system, electrical components, and adjustment of electrical variables, etc., which can solve the problems of N-MOS tube current or voltage increase, failure, and increase, so as to improve reliability and simplify the circuit , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

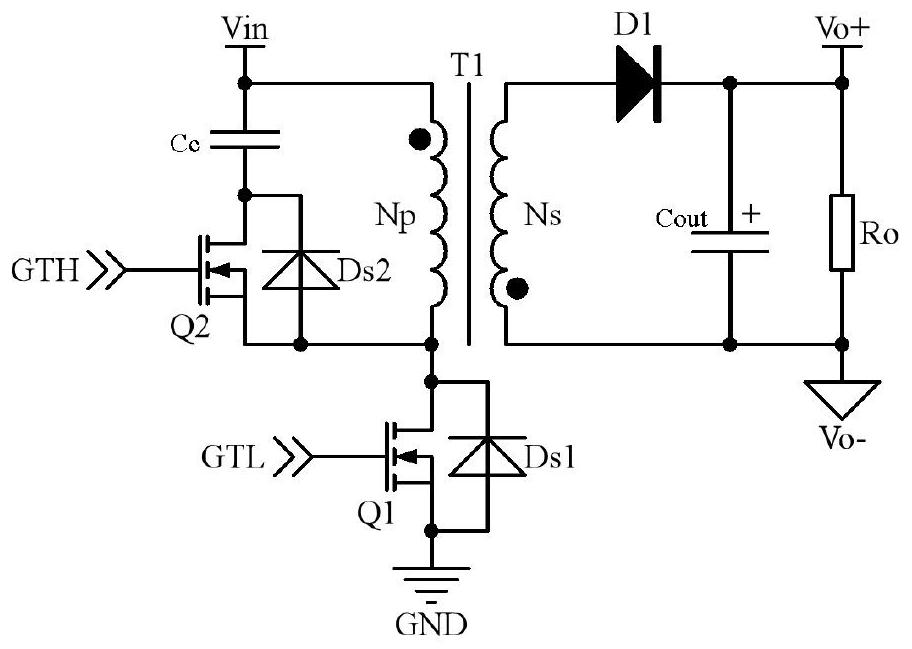

[0077] Such as Figure 5 As shown, it is the schematic circuit diagram of the first embodiment of the present invention, and the dotted line box 501 is the synchronous rectification control circuit of the present invention, and image 3 The difference of the synchronous rectification control circuit is that it also includes: N-MOS tube Q3, isolation transformer T2, resistor R2, capacitor C3 and resistor R3. In addition, the synchronous rectification control chip U1 also includes the enable signal pin SYN; the resistor One end of R2 is used to input the working voltage VDD, the other end of resistor R2 is connected to the drain of N-MOS transistor Q3 and one end of capacitor C3 at the same time, the drive signal input by the gate of N-MOS transistor Q3 and the gate of clamping transistor Q2 The input drive signal is the same as GTH, the source of N-MOS transistor Q3 is connected to one end of resistor R3, the opposite end of the primary side of isolation transformer T2 and the ...

no. 2 example

[0082] Such as Figure 7 As shown, it is the circuit schematic diagram of the second embodiment of the present invention, and the dotted line box 701 is the synchronous rectification control circuit of the present invention. Compared with the first embodiment of the present invention, the difference of the second embodiment is that it also includes a diode D3 , capacitor C1, capacitor C2 and resistor R1, the anode of the diode D3 is connected to the primary end of the isolation transformer T2 with the same name, the cathode of the diode D3 is connected to the primary end of the isolation transformer T2 with the same name, and the capacitor C2 is connected across the primary end of the isolation drive transformer T2 Both ends of the side winding, the capacitor C1 and the resistor R1 are connected in parallel across the two ends of the secondary winding of the isolation transformer T2.

[0083] After adding diode D3 and capacitor C2, the high-frequency interference signal of the...

no. 3 example

[0087] Such as Figure 8 As shown, it is the circuit principle diagram of the third embodiment of the present invention, and the dotted line box 801 is the synchronous rectification control circuit of the present invention. Compared with the second embodiment of the present invention, the difference of the third embodiment is that it also includes a diode D1 And the diode D2, the diode D1 and the diode D2 are connected in antiparallel and connected across the secondary winding of the isolation drive transformer T2.

[0088] Diode D1 and diode D2 are added, and the voltage at both ends of the secondary winding of the isolation drive transformer T2 will be clamped by the diodes to ensure that the amplitude of the secondary excitation voltage signal SYN is too large or too small to damage the synchronous rectification control chip U1. circuit reliability.

[0089] Compared with the second embodiment of the present invention, the basic working principle of the third embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com