Micropore manufacturing method suitable for liquid crystal polymer substrate

A technology of liquid crystal polymers and production methods, applied in the processing of insulating substrates/layers, printed circuit manufacturing, printed circuits, etc., can solve the problems of low production efficiency, high equipment precision requirements, and inability to effectively solve the problem of peeling heat between dielectric and conductor layers Melt shrinkage and other problems to achieve high efficiency and ensure the effect of pass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 LCP flexible substrate microhole production equipment

[0050] The LCP flexible substrate micropore production equipment in this embodiment is used to match the production of liquid crystal polymer flexible substrate micropores by using etching confinement technology.

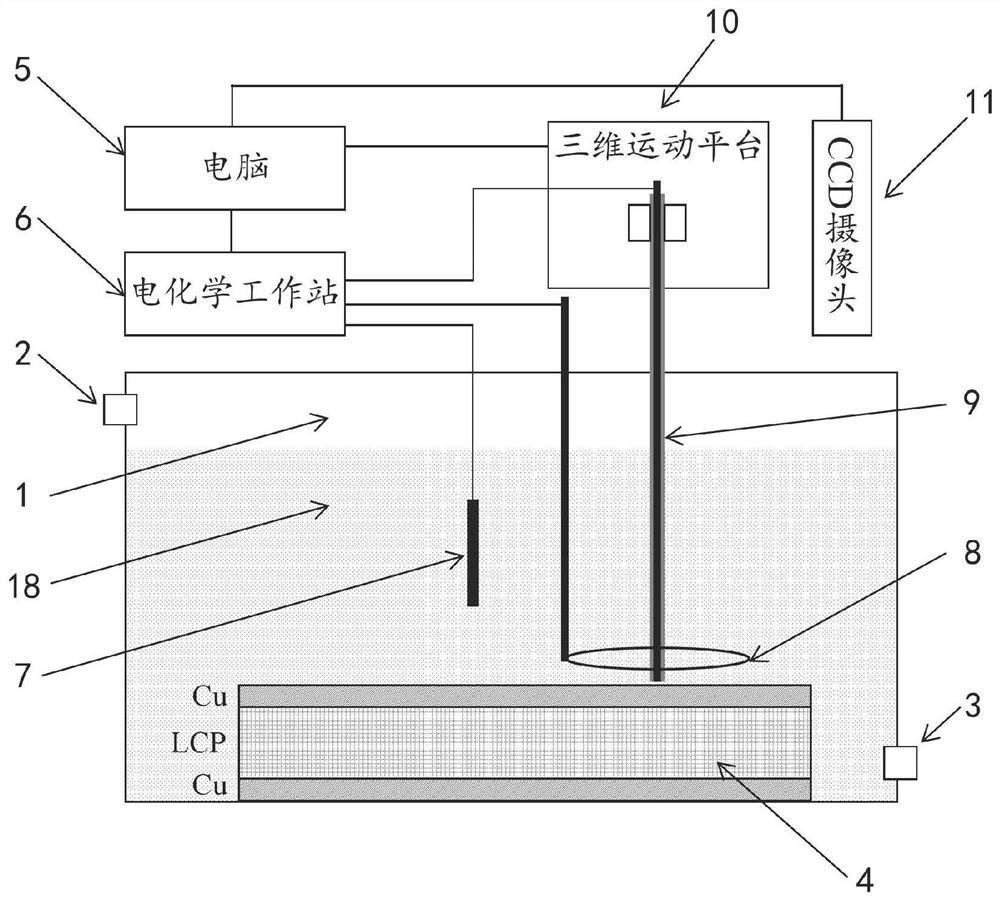

[0051] Such as figure 1 As shown, the LCP flexible substrate micropore manufacturing equipment in the present embodiment comprises a container 1, an electrochemical workstation 6, an electrode connected to the electrochemical workstation 6, a control module (computer 5), a motion module (three-dimensional motion platform 10) and a visual module (CCD camera 11). The electrochemical workstation 6, the motion module and the vision module are respectively connected with the control module.

[0052] The container 1 is used to accommodate the LCP flexible substrate 4 and the electrolyte solution 18, and its top is provided with a liquid inlet 2, and the bottom of the container 1 is provided with...

Embodiment 2

[0055] Embodiment 2 is applicable to the micropore fabrication method of liquid crystal polymer substrate

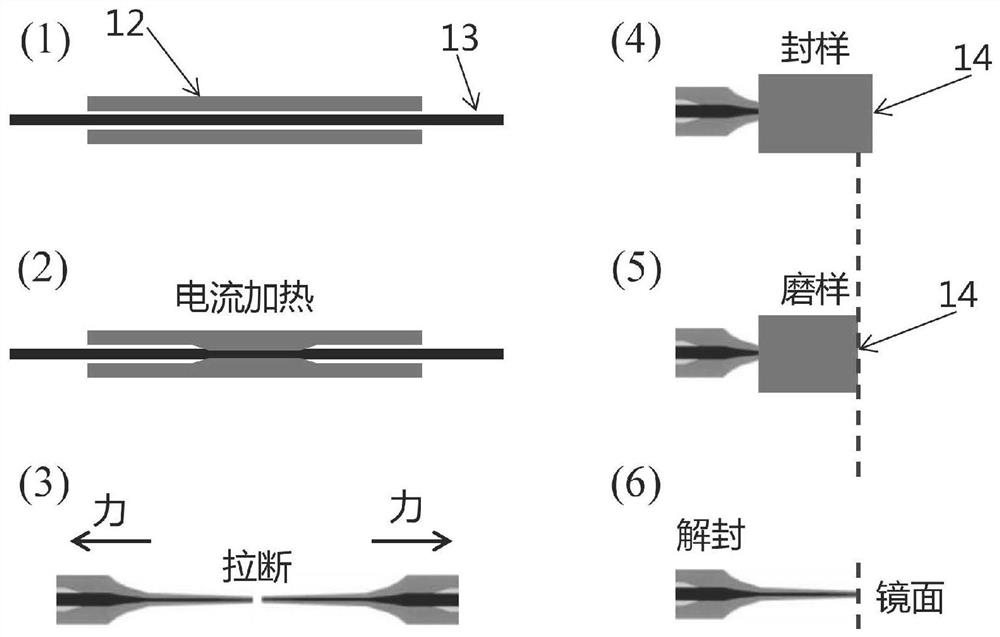

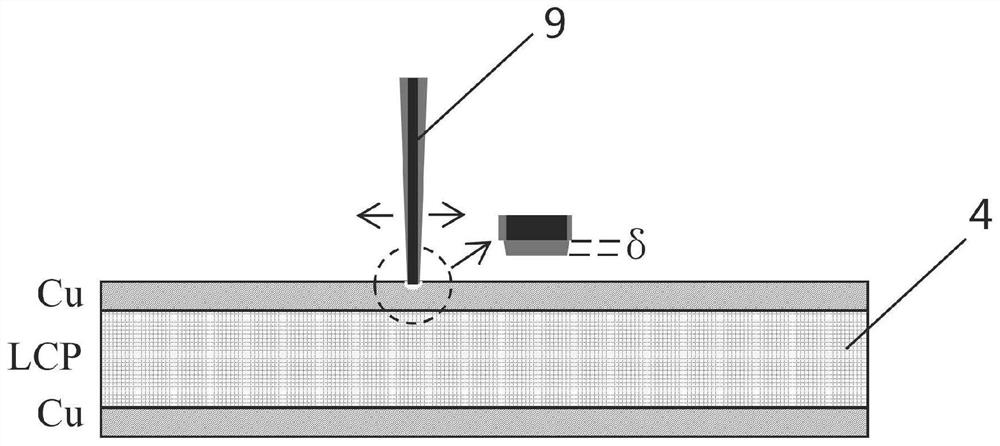

[0056] This embodiment provides a method for manufacturing micropores on a liquid crystal polymer flexible substrate based on the etching constraint technology and the LCP flexible substrate micropore manufacturing equipment in Example 1, which specifically includes the following steps:

[0057] 1. Preparation of copper layer etching-constraint system electrolyte solution

[0058] The etching-constrained system electrolyte solution of copper layer in the present embodiment comprises the composition of following molar concentration: 0.04mol / L FeCl 2 , 0.012mol / L bipy, 0.2mol / L SnCl 2 , 0.2mol / L HCl.

[0059] Electrolyte solution 18 adopts a chemical solution preparation method, weighs a specific mass of corresponding electrolyte substance according to the above molar concentration, dissolves it in a specific volume of deionized water, and mixes it uniformly.

[0060] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com