Polymer, coating composition comprising same, and organic light emitting device using same

A polymer, integer technology, applied in the field of polymers, can solve the problems of changing the concentration gradient of the solution, the material cannot be dissolved well, and defective devices, etc., and achieve the effect of reducing the driving voltage, excellent solubility, and improving the service life characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0383] According to another exemplary embodiment, the first electrode is a negative electrode and the second electrode is a positive electrode.

[0384] The organic light emitting device of the present invention can be stacked into the structures in the following examples.

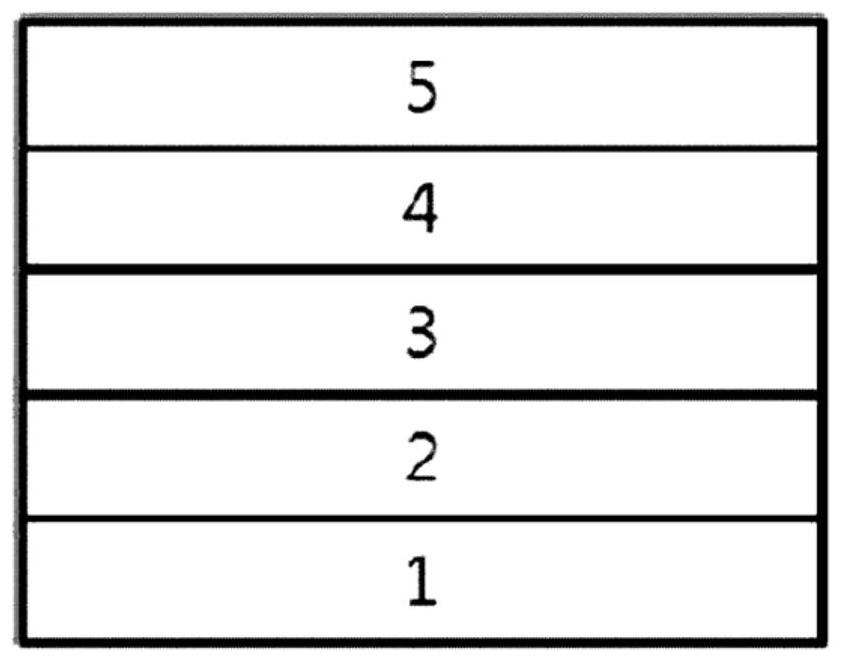

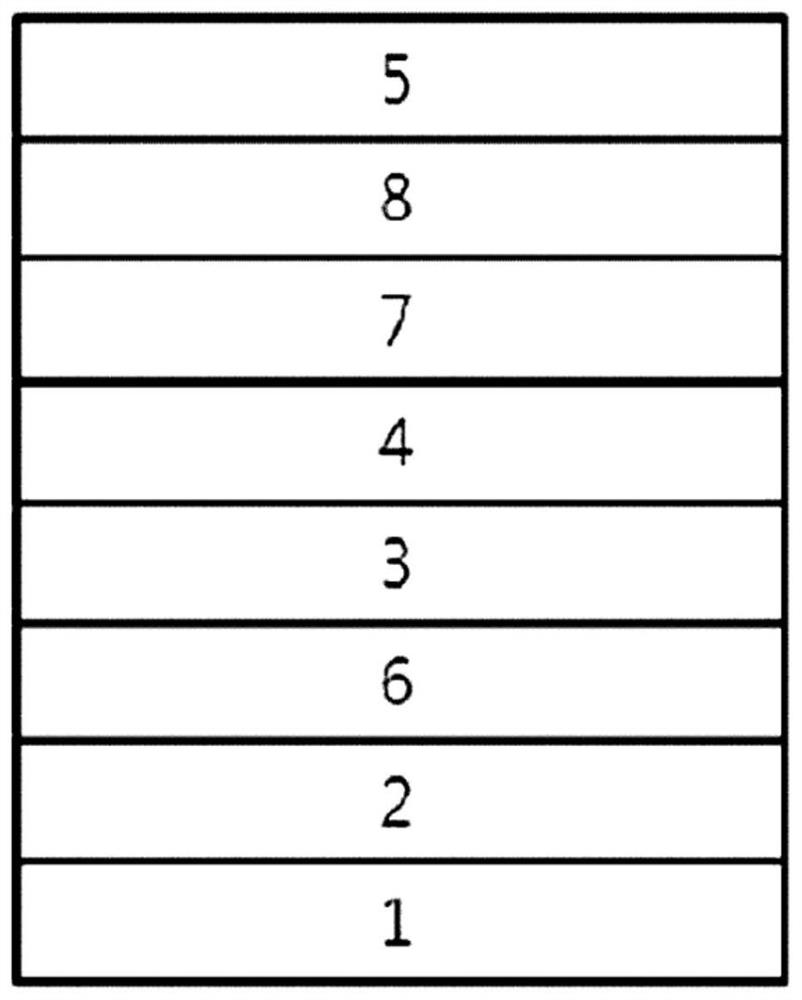

[0385] (1) Positive electrode / hole transport layer / luminescent layer / negative electrode

[0386] (2) Positive electrode / hole injection layer / hole transport layer / light emitting layer / negative electrode

[0387] (3) Positive electrode / hole injection layer / hole buffer layer / hole transport layer / light-emitting layer / negative electrode

[0388] (4) Positive electrode / hole transport layer / luminescent layer / electron transport layer / negative electrode

[0389] (5) Positive electrode / hole transport layer / luminescent layer / electron transport layer / electron injection layer / negative electrode

[0390] (6) Positive electrode / hole injection layer / hole transport layer / light emitting layer / electron transport layer / neg...

Synthetic example 1

[0436] Synthesis Example 1: Preparation of Polymer Compound 1

[0437]

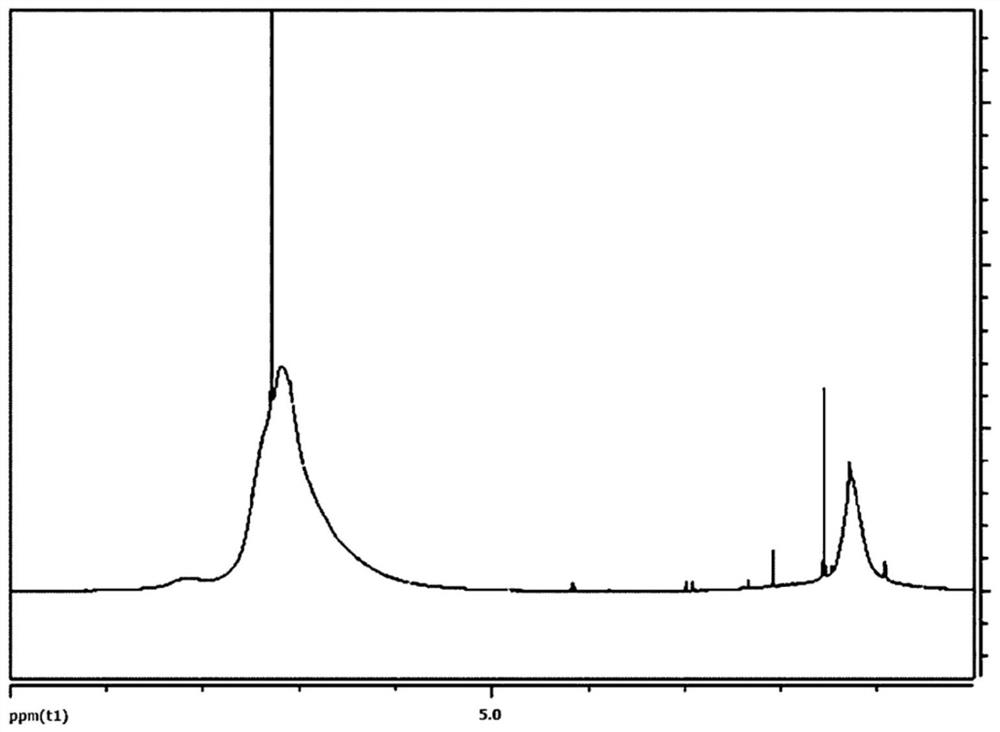

[0438] After monomer 1-a (1.0g, 1.17mmol), monomer 1-b (1.0g, 1.28mmol), and initiator 1-c (5.0mg, 0.015mmol) were put into a Schlenk flask and dissolved in toluene (5.0 ml), the freeze-vacuum-thaw process was repeated three times, and the resulting product was stirred at 120° C. for 7 hours. After the reaction was completed, a polymer was obtained by pouring the solution into methanol to produce a precipitate. After the polymer obtained by filtration was stored in a vacuum oven, remaining monomers were removed through an adsorption column (hexane:methyl chloride=5:5), and the polymer solution obtained by flowing toluene was evaporated. Thereafter, a precipitate was generated in methanol, which was filtered and then dried in a vacuum oven to obtain Polymer 1. Polymerization, molecular weight, and molecular weight distribution of the polymer were determined by 1H-NMR and GPC analysis.

[0439] imag...

Synthetic example 2

[0441] Synthesis Example 2: Preparation of Polymer Compound 2

[0442]

[0443] Polymer 2 was synthesized in the same manner as in Synthesis Example 1 except that 2.0 g (2.34 mmol) of Monomer 1-a and 1.0 g (1.28 mmol) of Monomer 1-b were used in Synthesis Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com