Drying treatment method and apparatus using same

A technology of drying treatment and treatment chamber, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of long time and low processing capacity, and achieves the improvement of contact area, efficiency and generation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

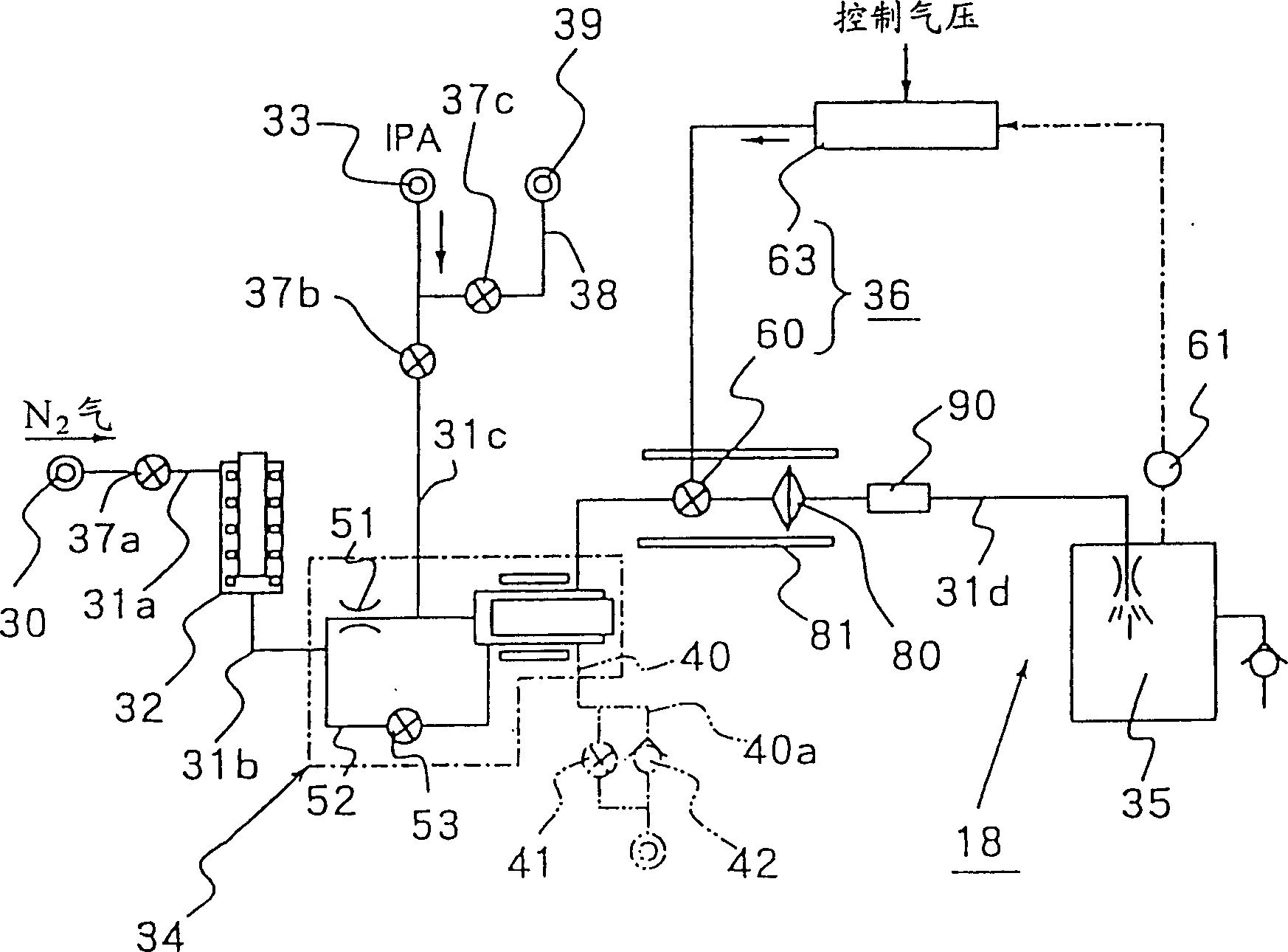

[0037]Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. These embodiments are applicable to semiconductor wafer cleaning processing systems.

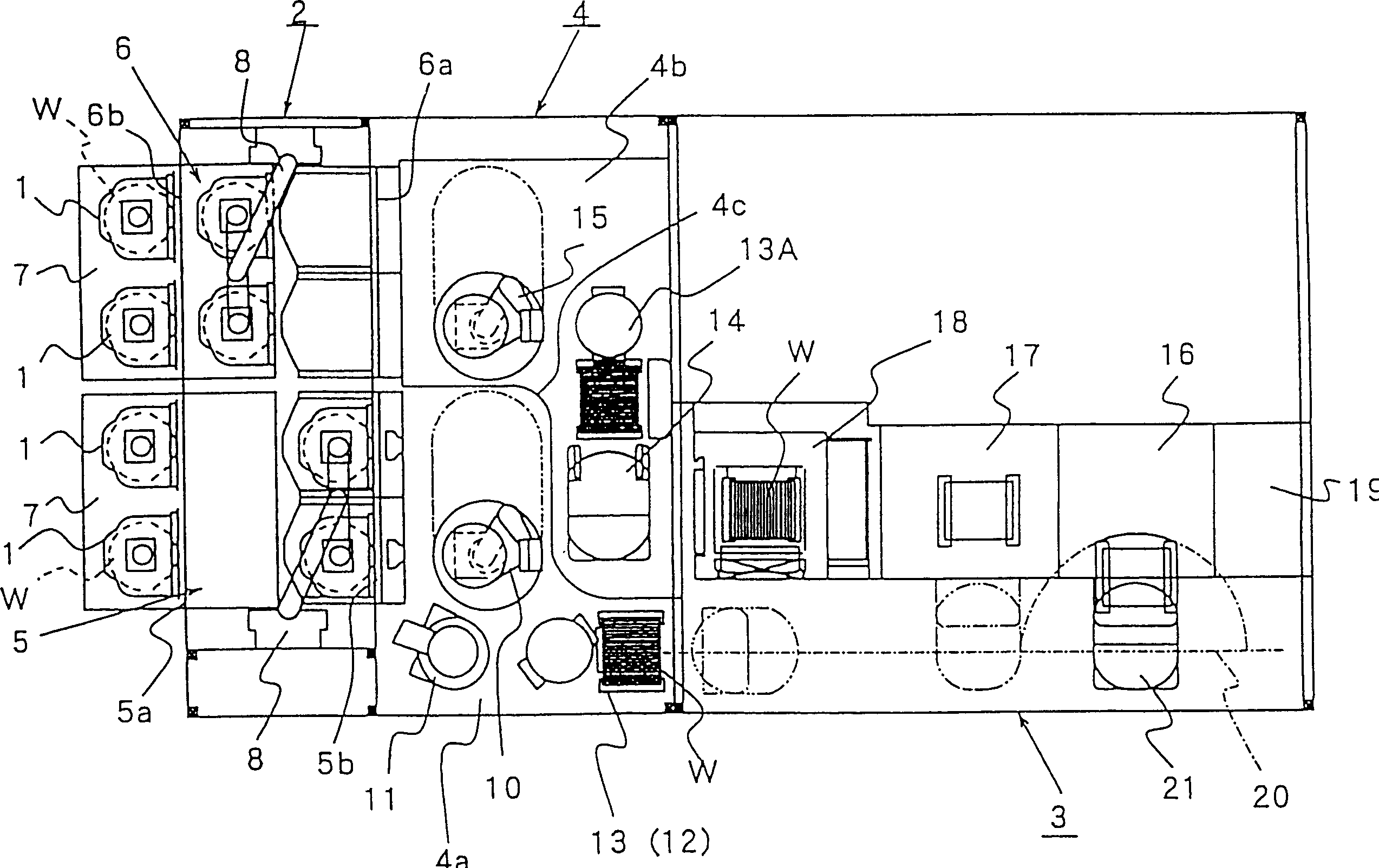

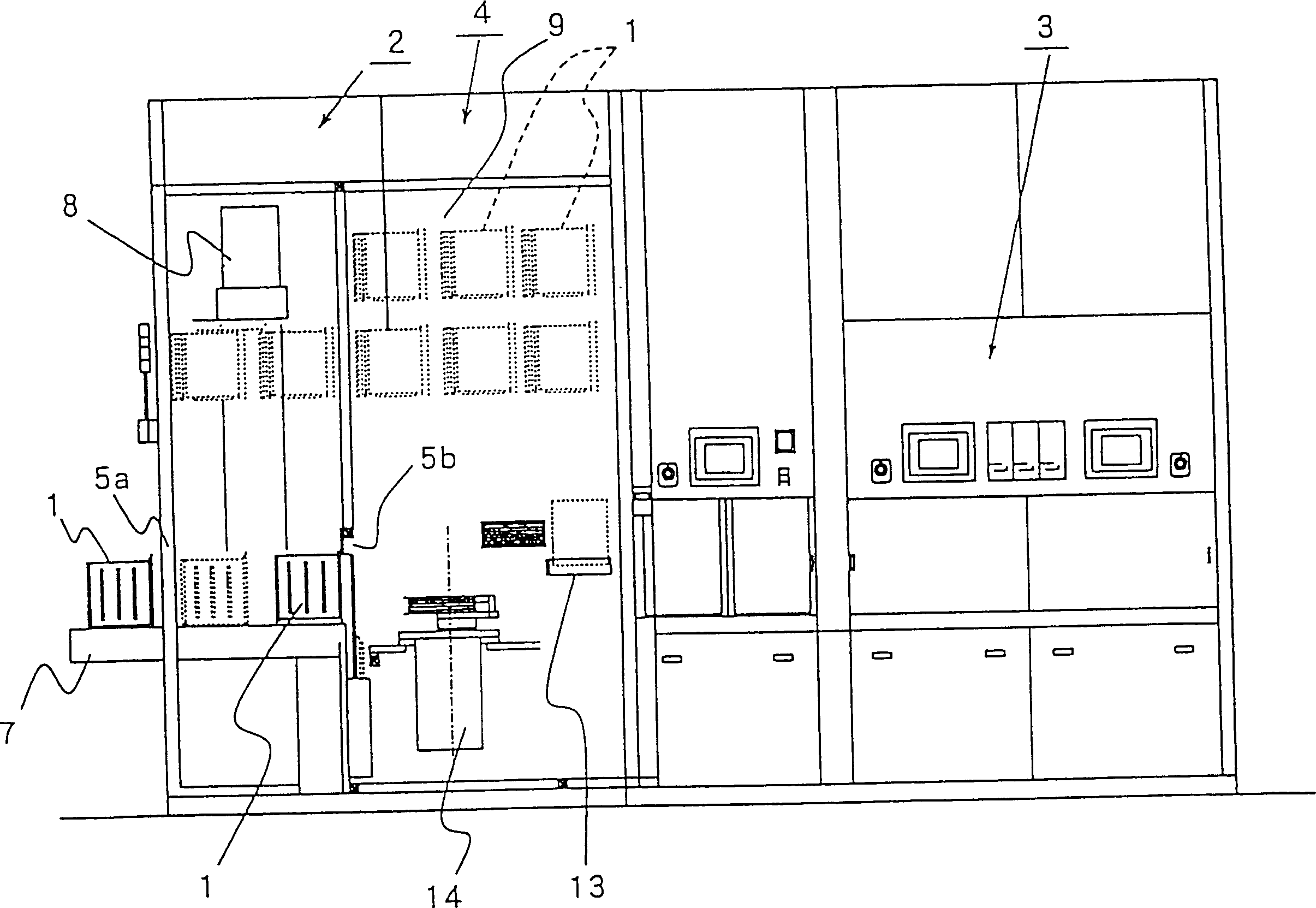

[0038] figure 1 is a schematic plan view of an example of a cleaning treatment system applicable to the drying treatment device of the present invention, figure 2 Is the side schematic diagram of the above cleaning system.

[0039] The above-mentioned cleaning processing system is mainly composed of a container for a semiconductor wafer W (hereinafter simply referred to as a wafer) that is accommodated in a horizontal state, such as a transport part 2 that is transported into or out of a carrier 1; The processing part 3 for cleaning liquid and other liquid processing and drying processing at the same time; the interface part 4 provided between the conveying part 2 and the processing part 3 for wafer transfer, position adjustment and posture change, etc. constitutes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com