Method for realizing sol-gel-sol autonomous transformation based on competitive reaction

A competitive reaction and sol technology, applied in the field of medical polymer materials, can solve the problems of high cost, unfriendliness, high price, etc., and achieve the effects of low cost, efficient reaction and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In Example 1, the preparation method of 200mg / mL F-127 solution: In an ice bath environment, add 60mL of deionized water to 20g of F-127, stir evenly, and set the volume to 100mL, store in the refrigerator for later use.

Embodiment 2

[0037] In Example 2, the preparation method of 300mg / mL F-68 solution: In an ice bath environment, add 60mL deionized water to 30g F-68, stir evenly, and set the volume to 100mL, store in the refrigerator for later use.

[0038] Example 1

[0039] A method for realizing sol-gel-sol autonomous transformation based on a competitive reaction, the method is carried out based on a competitive reaction system,

[0040] Configure the competing response system:

[0041] Add 1 mL of deionized water to the centrifuge tube at room temperature, add 100 mg of α-amylase to dissolve completely, add 1 mL of 200 mg / mL F-127 solution, mix well at room temperature, then add 160 mg of α-cyclodextrin to the centrifuge tube and mix well .

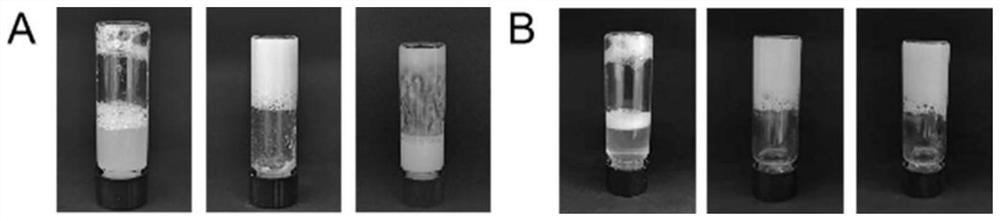

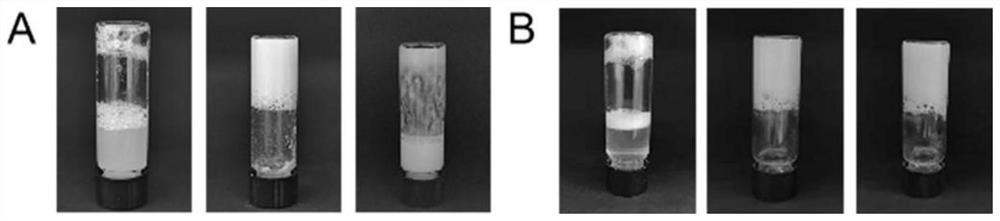

[0042] After the above components are mixed evenly, F-127 and cyclodextrin form a gel through supramolecular interaction in about 20 minutes. At the same time, α-amylase in the system is added to hydrolyze the cyclodextrin so that the gel gradually disintegrat...

Embodiment 3

[0055] A method for realizing sol-gel-sol autonomous transformation based on a competitive reaction, the method is carried out based on a competitive reaction system,

[0056] Configure the competing response system:

[0057] Add 1 mL of deionized water to the centrifuge tube at room temperature, add 160 mg of amylase to dissolve completely, add 1 mL of 360 mg / mL F-127 solution, mix well at room temperature, then add 120 mg α-cyclodextrin to the centrifuge tube and mix well.

[0058] After the above components are mixed evenly, F-127 and α-cyclodextrin form a gel through supramolecular interaction in about 20 minutes. At the same time, amylase in the system is added to hydrolyze the cyclodextrin to make the gel gradually disintegrate, and finally, F- 127 mixed with glucose and amylase to complete a complete autonomous transformation process from sol to gel and then to sol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com