Cold flow fiber forming extrusion molding method and device for polytetrafluoroethylene film

A polytetrafluoroethylene film and extrusion molding technology, which is applied in the field of polytetrafluoroethylene film processing, can solve the problems of inconspicuous fiberization of polytetrafluoroethylene particles and the inability to realize continuous production, etc., to solve the problem of difficult feeding, Improve the fiber length and node density, improve the effect of product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

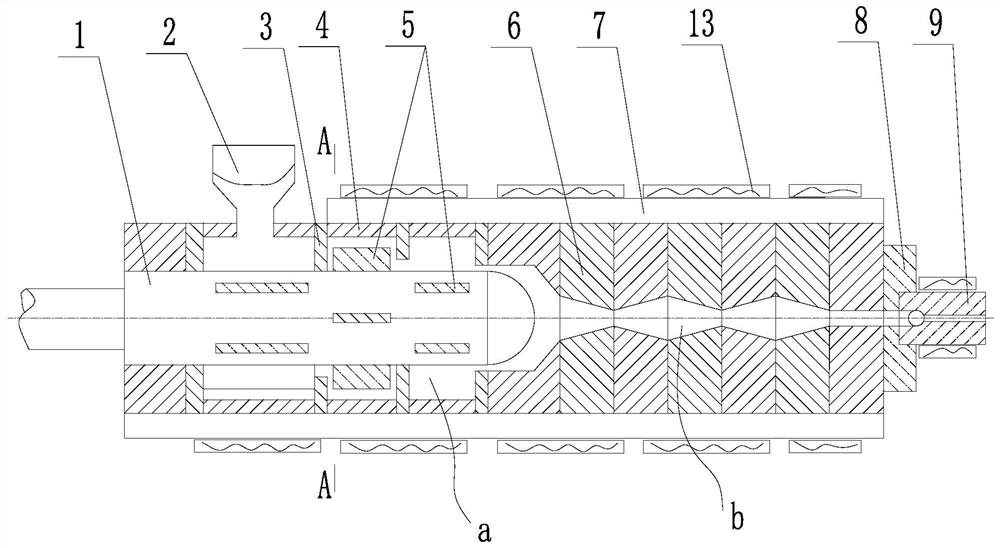

[0035] A kind of cold flow fiber forming extrusion molding device of polytetrafluoroethylene in this embodiment, such as figure 1 As shown, its main components include blade shaft 1, hopper 2, baffle plate 3, stator 4, blade 5, stretching module 6, sleeve 7, connecting seat 8 and die head 9, forming blades connected in sequence along the material conveying direction Conveying unit a and stretching unit b.

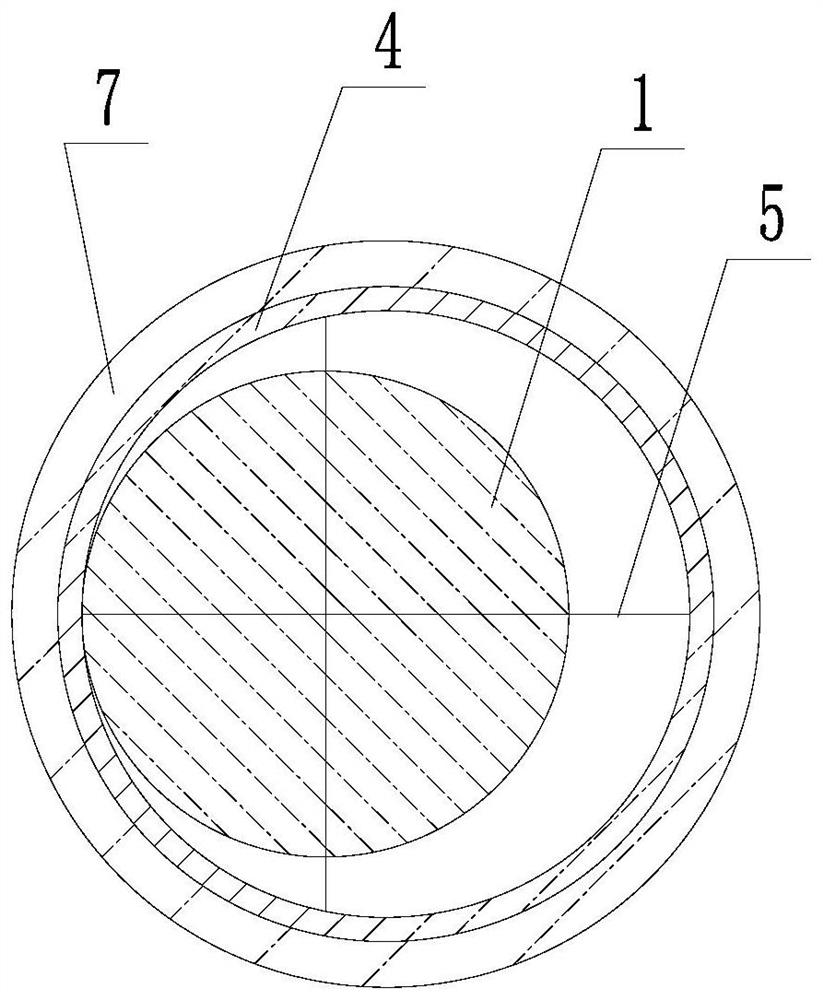

[0036]The specific structure of the blade conveying unit is: the stator and the baffle are placed in the front section of the sleeve, the stator is a multi-section structure, a baffle is arranged between any two adjacent stators, and the baffle extends from the inside of the stator to the inner cavity of the stator . There are multiple blades distributed on the cylindrical surface of the blade shaft. The blades are telescopically installed in the preset slots of the blade shaft. The blades are arranged in multiple groups. The same group of blades is located on the same axi...

Embodiment 2

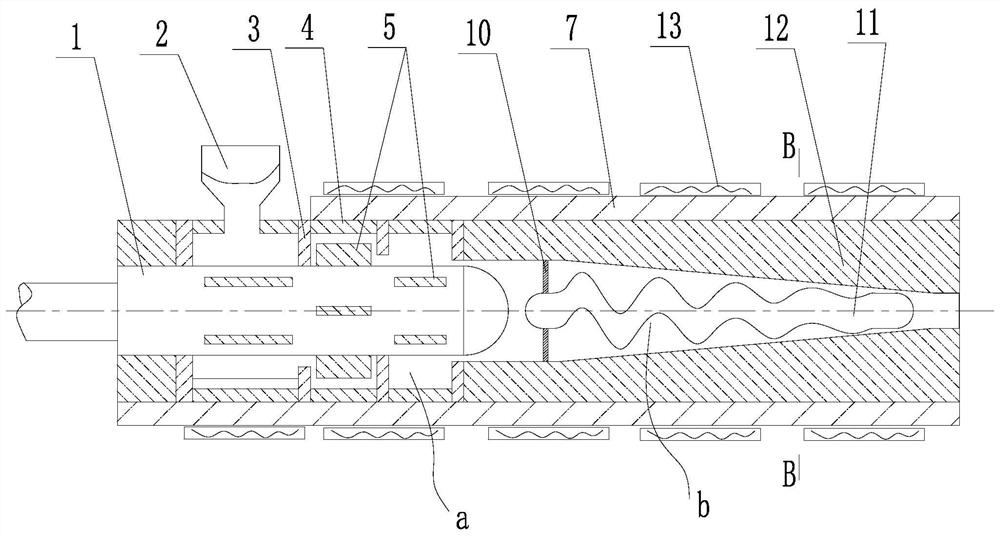

[0040] This embodiment is a polytetrafluoroethylene cold-flow fiber-forming extrusion molding device. Compared with Embodiment 1, the difference lies in that the specific structure of the stretching unit is different.

[0041] Such as image 3 As shown, in this embodiment, the stretching unit adopts the form of coaxial assembly of the stretching shaft 11 and the stretching barrel 12 , the stretching shaft is in a spiral shape as a whole, and is fixed in the stretching barrel by the three-claw bracket 10 . Along the axial direction, the radial height of the stretching shaft decreases gradually, the inner diameter of the stretching barrel decreases gradually, and the flow channel volume of adjacent screw pitches gradually decreases. In the stretching runner, the PTFE resin advances helically along the pulling axis, due to the change of the axial space of the runner (such as Figure 4 As shown), under the action of tensile force, the PTFE resin particles will undergo the process...

Embodiment 3

[0043] This embodiment is a polytetrafluoroethylene cold-flow fiber-forming extrusion molding device. Compared with Embodiment 2, the difference lies in that the specific structures of the stretching shaft and the stretching barrel in the stretching unit are different.

[0044] Such as Figure 5 As shown, in this embodiment, along the axial direction, the inner diameter of the stretching barrel remains unchanged, and the radial height of the stretching shaft also remains constant, but the pitch of the stretching shaft decreases gradually, so that the flow channel volume of adjacent pitches slowing shrieking. In addition, according to the actual needs of polymer material melt extrusion-flow / calendering, the radial section of the stretching unit can also adopt other shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com