Modified cyanate ester resin as well as preparation method and application thereof

A cyanate ester resin and cyanate ester technology, applied in the field of cyanate ester resin, can solve the problems of high crosslinking density, high cyanate ester curing temperature, limited space for improving the dielectric properties of pure cyanate ester resin, etc. The effect of improving wave transmission performance and reducing dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

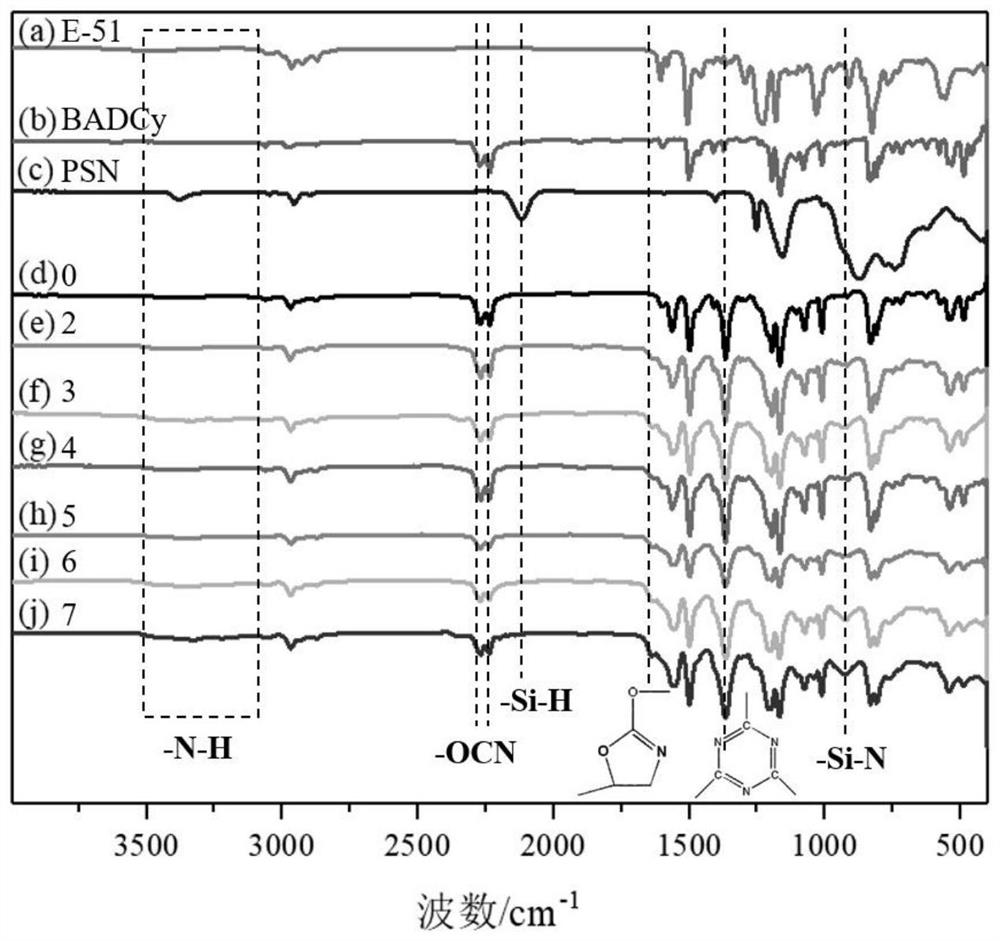

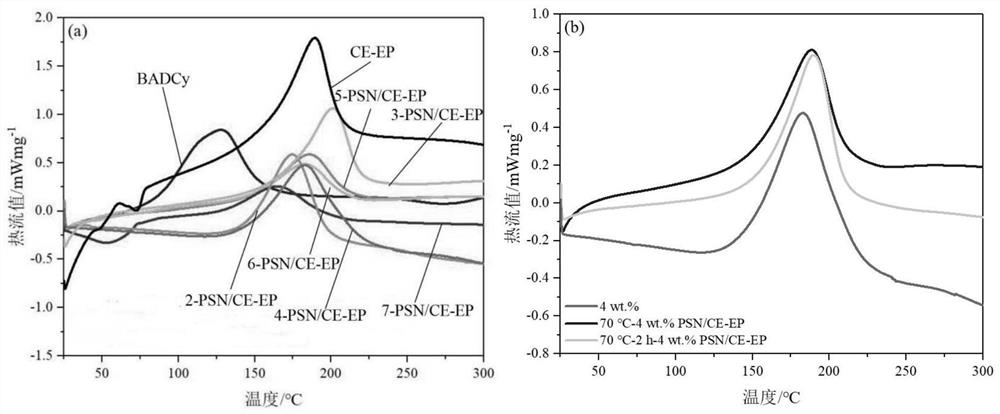

[0047] Heat 100g of BADCy and 5g of E-51 to 160°C, mix well, and react until the sample has no crystallization phenomenon, which is recorded as CE-EP prepolymer, wherein the mass of E51 is 5% of the mass of BADCy;

[0048] Step 2. At 25°C, add the pretreated PSN to the prepolymer in step 1, wherein the added mass of the pretreated PSN is 2% of the prepolymer to obtain a modified cyanate, denoted as 2 -PSN / CE-EP.

[0049] The pretreated PSN was prepared according to the following method: put the original PSN into a round-bottomed flask, and use a rotary evaporator to perform rotary evaporation treatment. The conditions of the rotary evaporation treatment are: the rotation speed is 120r / min, and the temperature is 40°C. In order to remove the ammonia in the PSN, obtain the pretreated PSN.

Embodiment 2

[0051] The method for preparing modified cyanate is the same as in Example 1, the difference is that in step 2, the added mass of PSN after pretreatment is 3% of the prepolymer to obtain modified cyanate, which is denoted as 3-PSN / CE -EP.

Embodiment 3

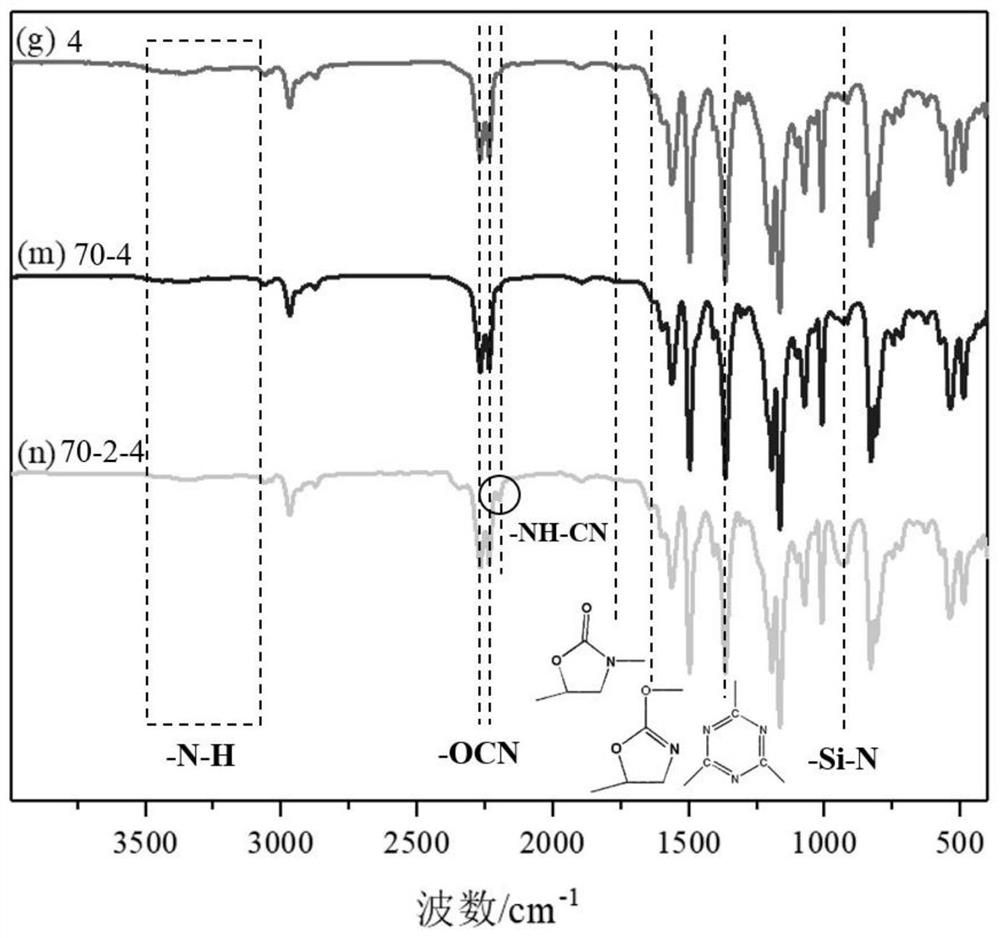

[0053] The method for preparing modified cyanate is the same as in Example 1, the difference is that in step 2, the added mass of PSN after pretreatment is 4% of the prepolymer to obtain modified cyanate, which is denoted as 4-PSN / CE -EP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com