Numerical simulation method in gas pipeline explosion venting process

A numerical simulation, gas pipeline technology, applied in the field of gas pipeline explosion venting, can solve the problems of inability to analyze gas pipeline explosion venting, not fully considering hydrogen deflagration to detonation and its suppression process, etc., to increase the effective area of the flame and increase the disturbance , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

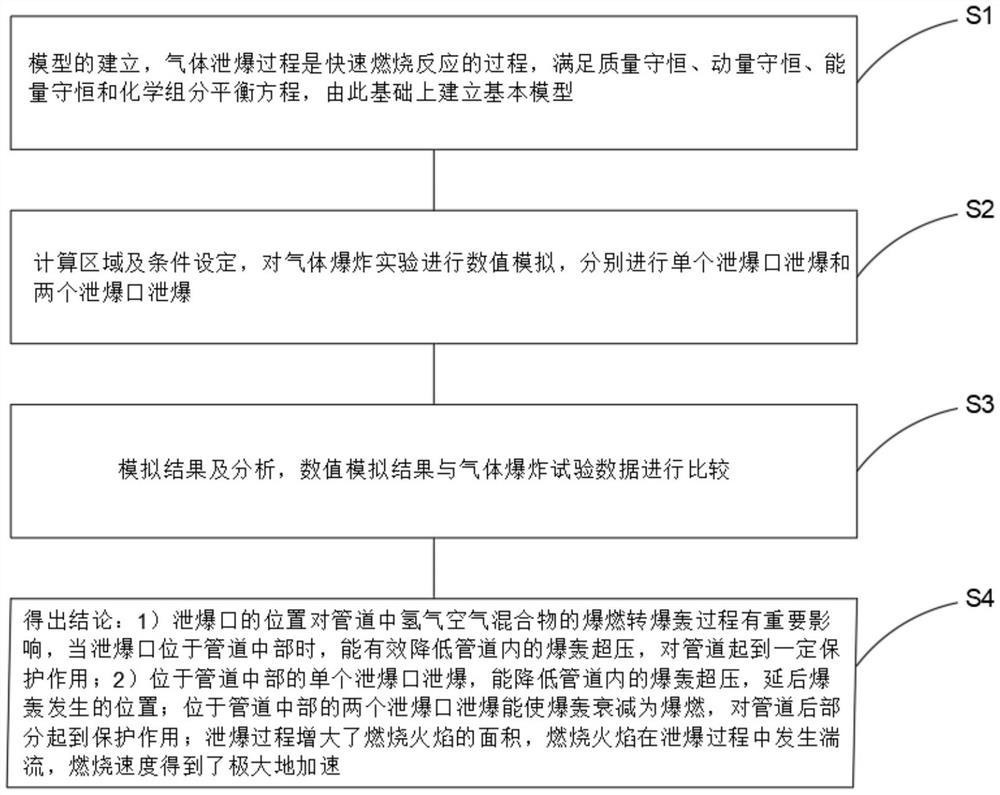

[0032] refer to figure 1 , a numerical simulation method in the gas pipeline explosion venting process, comprising the following steps:

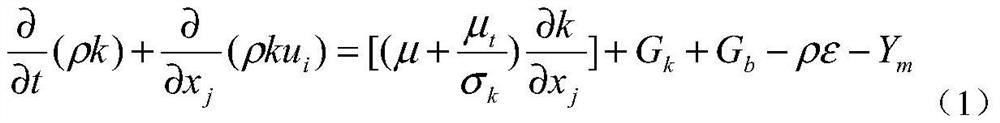

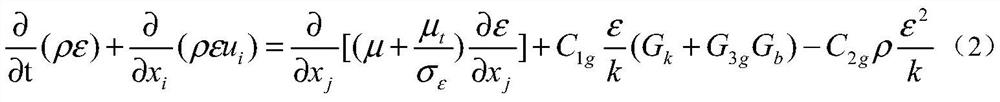

[0033] S1. The establishment of the model. The gas venting process is a process of rapid combustion reaction, which satisfies the mass conservation, momentum conservation, energy conservation and chemical composition balance equations, and establishes the basic model on this basis;

[0034] S2. Calculation area and condition setting, carry out numerical simulation to the gas explosion experiment, respectively carry out the explosion venting of a single explosion vent and the explosion venting of two explosion vents;

[0035] S3, simulation results and analysis, the numerical simulation results are compared with the gas explosion test data;

[0036] S4, draw conclusions: 1) the position of explosion vent has important influence on the deflagration-to-detonation process of the hydrogen-air mixture in the pipeline, when the explosion vent is l...

Embodiment 1

[0047] The simulation operation of the gas explosion experiment can be simplified as an axisymmetric model of the spherical container and the explosion venting duct. The inner diameter of the spherical explosion venting container is 350mm; the inner diameter of the explosion venting duct is 50mm, and the length is 165mm; The inside is filled with methane and air mixed according to the stoichiometric ratio, and the outside of the container is air; assuming that the center of the container encounters an ignition source and explodes, the ignition temperature is 2000K, and 10% of the fuel in the ignition area is consumed at the instant of ignition.

[0048] In step S2, the position of the explosion vent in the explosion venting of the single explosion vent is 0.4, 1.6, and 2.0m from the ignition end. The limitation of the venting area and venting rate of the blast vent failed to prevent the occurrence of detonation. At the same time, due to the existence of the blast vent, the dist...

Embodiment 2

[0052] The simulation operation of the gas explosion experiment can also use a closed circular tube with a length of 4m and an inner diameter of 0.106m as the explosion vessel. One end is ignited, and there is an annular obstacle with a blocking ratio of 0.92 and an inner diameter opening of 0.03m at a distance of 1m from the ignition end. A pressure sensor is set every 0.5m to monitor the pressure change after the obstacle is installed, and the establishment of the physical model is completely consistent with the experimental device.

[0053] In step S2, the position of the explosion vent in the explosion venting of the single explosion vent is 0.4, 1.6, and 2.0m from the ignition end. The limitation of the venting area and venting rate of the blast vent failed to prevent the occurrence of detonation. At the same time, due to the existence of the blast vent, the disturbance of the gas in the pipeline was increased, turbulent flow was generated, and the effective area of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com