PROPYLENE-ETHYLENE-alpha-OLEFIN COPOLYMER, PROPYLENE POLYMER COMPOSITION AND USE THEREFOR

An olefin copolymer and polymer technology, applied in coatings, adhesives, etc., can solve the problems of insufficient performance of propylene-based polymers, exudation of propylene-based polymer components, deterioration of surface characteristics of molded bodies, etc., and achieve appearance retention. Excellent effect, excellent tack resistance, excellent whitening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0181]

[0182] This composition can be mixed by various known methods, such as Henschel mixer, V-blender, ribbon mixer, drum mixer, kneading extruder, etc. method, or use a single-screw extruder, twin-screw extruder, kneader, Banbury mixer, etc. to melt and knead, thereby preparing. Moreover, granulation, pulverization, etc. may be performed as needed.

[0183] When performing the aforementioned mixing and kneading, each component to be blended may be added at one time or may be added in stages.

[0184] "Pellets"

[0185] The pellet according to one embodiment of the present invention contains the aforementioned copolymer (A) or the aforementioned present composition.

[0186] The shape, size, etc. of the pellets are not particularly limited, and can be appropriately selected according to the intended use.

[0187] The pellets can be produced by melting and granulating the above-mentioned copolymer (A) with a mixer such as a Banbury mixer, a roll, or an extruder. The i...

Embodiment

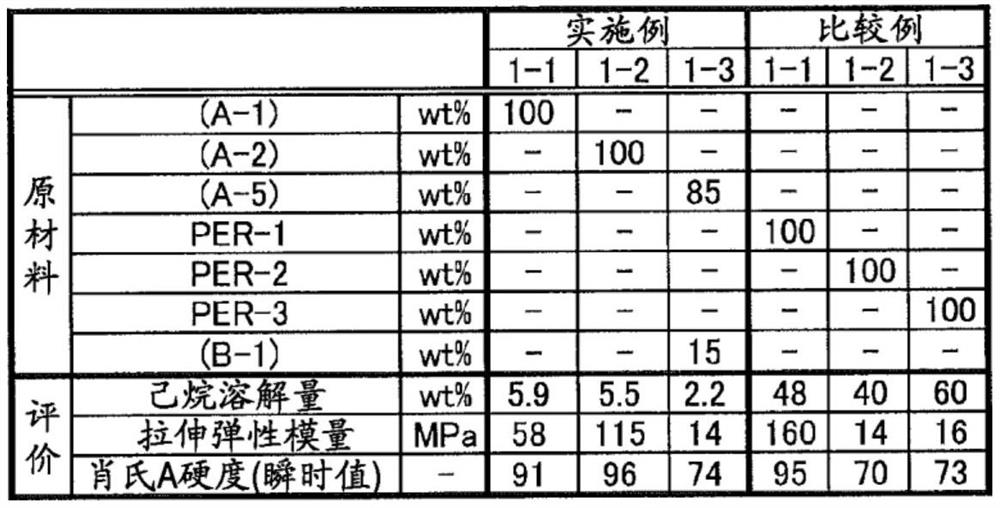

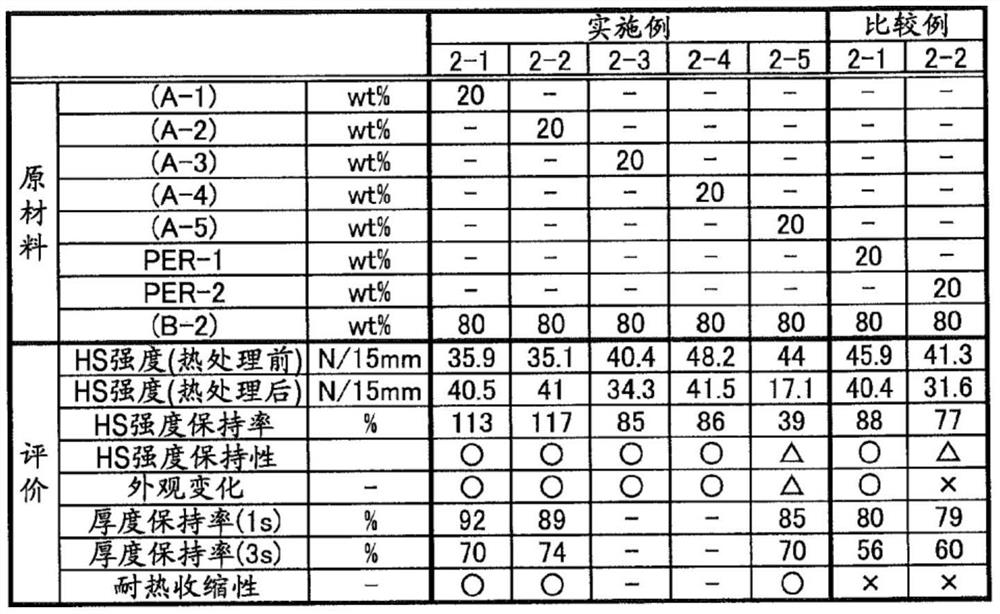

[0212] Hereinafter, the present invention will be described using examples, but the present invention is not limited to these examples.

[0213]

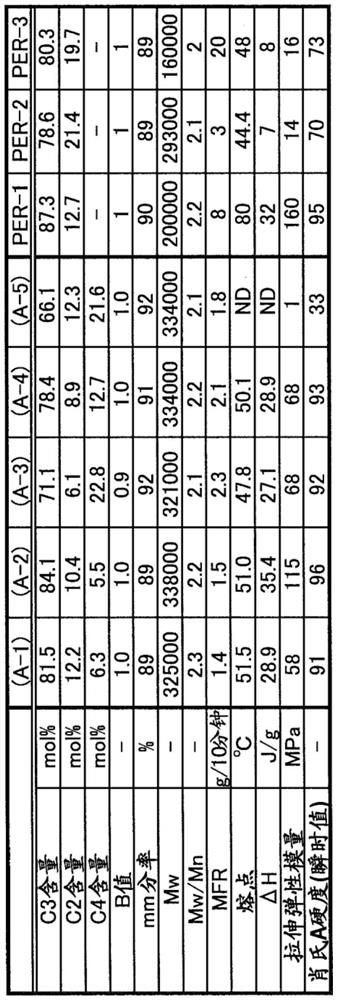

[0214] Propylene·ethylene·α-olefin copolymer (A):

[0215] Propylene·ethylene·α-olefin copolymers (A-1) to (A-5) obtained in the production examples described later were used.

[0216] Propylene-ethylene copolymer (PER):

[0217] Propylene / ethylene copolymers (PER-1) to (PER-3) obtained in Production Examples described later were used.

[0218] ・Propylene polymer (B):

[0219] (B-1); homopolypropylene ((Prime Polymer Co., Ltd., Prime Polypro F107, MFR (230°C, 2.16kg load) = 7g / 10min, melting point = 163°C, mmmm fraction = 96% )

[0220] (B-2); Atactic polypropylene ((Prime Polymer Co., Ltd., Prime Polypro F227, ethylene content = 3.0 mol%, MFR (230° C., 2.16 kg load) = 7 g / 10 minutes, melting point = 150 ℃, mmmm fraction = 96%)

[0221] (B-3); homopolypropylene ((Prime Polymer Co., Ltd., Prime Polypro J106, MFR (230°C, 2.16k...

manufacture example

[0228] As a catalyst for polymerization, diphenylmethylene (3-tert-butyl-5-ethylcyclopentadienyl) (2,7-di tert-Butylfluorenyl) zirconium dichloride, as a cocatalyst, using methylaluminoxane (manufactured by Tosoh Finechem Corporation, 0.3 mmol in terms of aluminum), using continuous polymerization equipment, ethylene used as a raw material in a hexane solution , propylene and 1-butene were polymerized to obtain six kinds of propylene·ethylene·α-olefin copolymers (A-1) to (A-5).

[0229] The physical property values of the obtained copolymers (A-1) to (A-5) were measured by the following methods. The results are shown in Table 1.

[0230] [Production example of propylene-ethylene copolymer (PER)]

[0231] Propylene-ethylene copolymers (PER-1) to (PER-3) were obtained in the same manner as in the production example of the aforementioned copolymer (A) except that the raw materials were changed to ethylene and propylene.

[0232] The physical property values of the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| enthalpy of fusion | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com