Production process of smooth and matte mobile phone backboard

A production process and mobile phone technology, applied in layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of inability to achieve discoloration, the pattern cannot show different colors, the pattern display effect is reduced, etc. Denaturation and plasticity, improving appearance and viewing effect, ensuring display stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

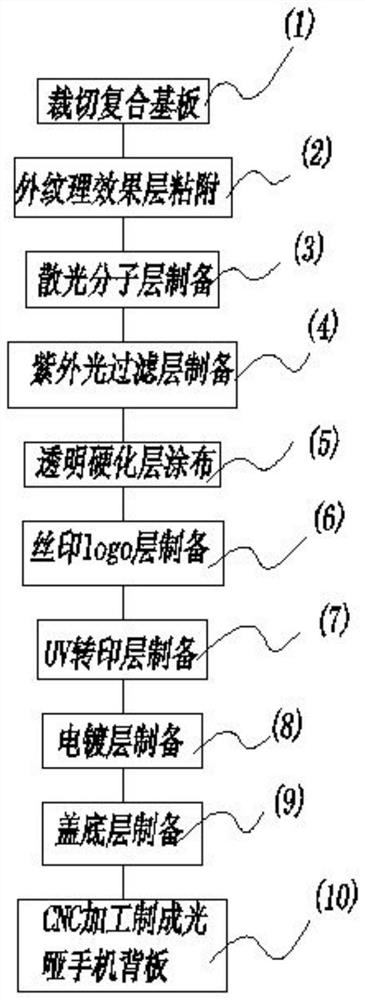

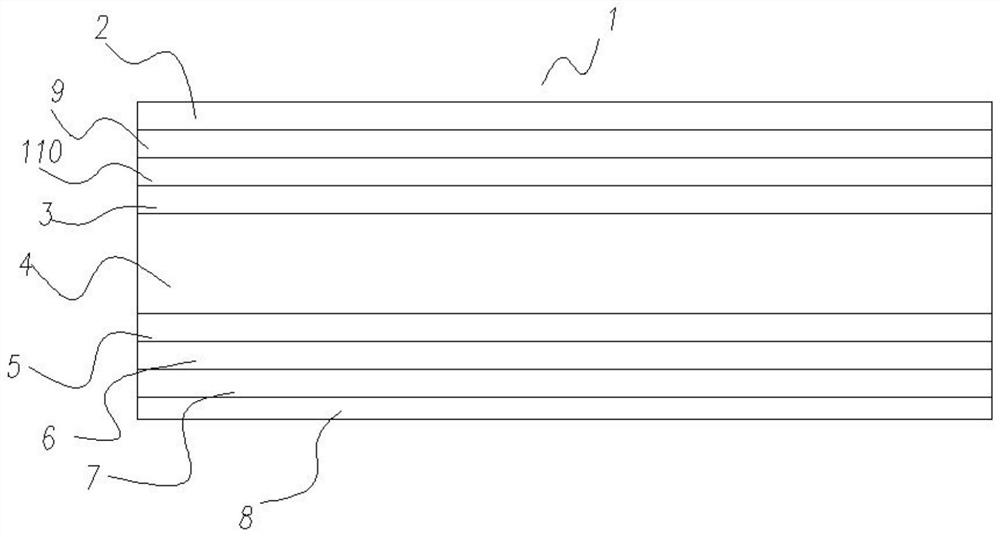

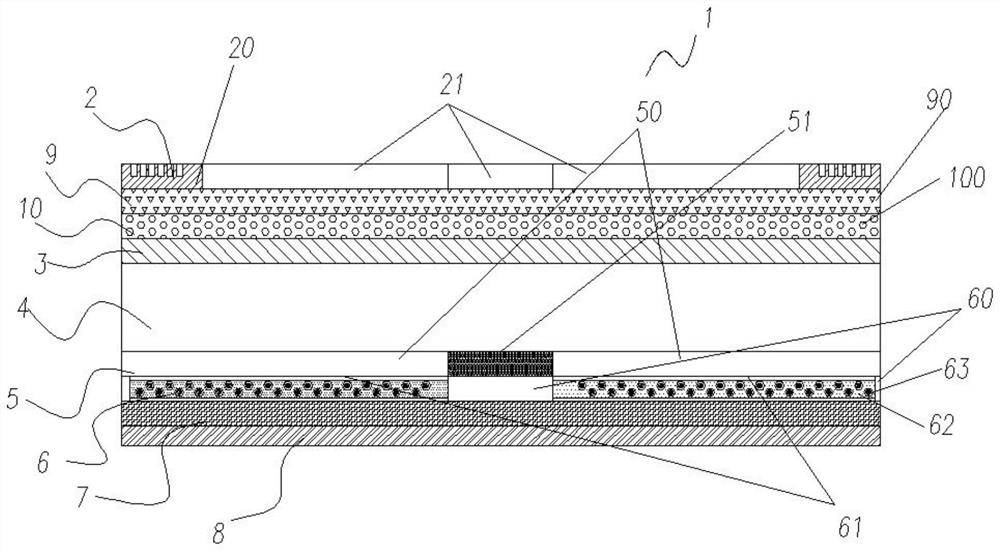

[0042] Examples, see attached Figure 1 ~ Figure 4, a matte mobile phone backplane production process, the matte mobile phone backplane 1 sequentially comprises a transparent hardened layer 2, an outer texture effect layer 3, a composite substrate 4, a silk screen logo layer 5, a UV transfer layer 6, an electroplating layer 7 and the cover bottom layer 8, between the transparent hardened layer 2 and the outer texture effect layer 3, an ultraviolet light filter layer 9 and a light-scattering molecular layer 10 are sequentially arranged from the outside to the inside, and the outer texture effect layer 3 is used to provide the outer texture Effect, the UV transfer layer 6 is provided with a transparent area 60 and a pattern area 61, the pattern area 60 is provided with an interlayer, the interlayer is provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com