Polyvinyl alcohol sponge with ordered porous structure prepared on basis of 3D printing template and application thereof

A technology of polyvinyl alcohol sponge and porous structure, applied in medical science, absorbent pads, pharmaceutical formulations, etc., to achieve excellent blood compatibility, excellent biocompatibility, eliminate biological safety and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

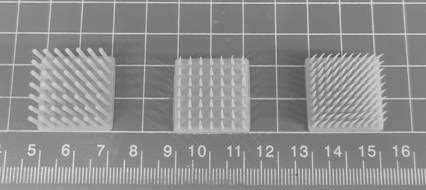

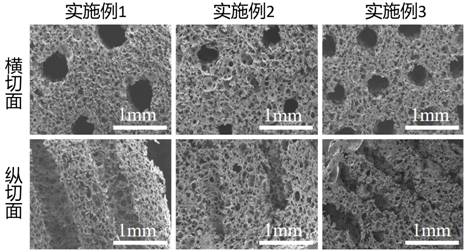

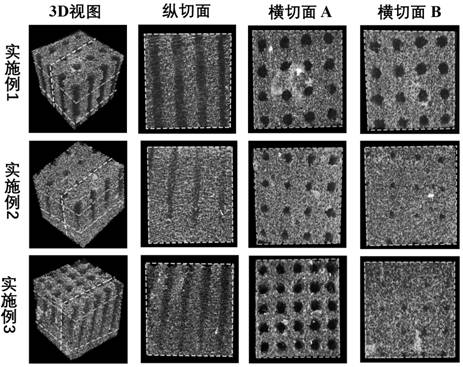

Embodiment 1

[0043] A polyvinyl alcohol sponge with an ordered porous structure prepared based on a 3D printing template is prepared by the following steps:

[0044] (1) Obtain a 3D printed sacrificial template by photolithography. Use liquid photosensitive resin as 3D printing material. First, a 3D hollow cube was designed on the SolidWorks 2019 software, and 49 cone structures with a taper of 0 were set inside. Import it into the printing software CHITUBOX as an STL format, and set the printing parameters. Finally, import the program into the 3D printer for printing.

[0045] (2) Dissolve polyvinyl alcohol in ultrapure water, prepare a polyvinyl alcohol suspension with a mass concentration of 5%-15%, and raise the temperature to 95°C. Add 1%-5% sodium alginate to it and cool to room temperature.

[0046] (3) Add 0.1%-0.5% foaming agent to (2), stir vigorously at 1500rmp for foaming, then add 0.25%-5% HCl (1mol / l).

[0047] (4) Add 0.025%-0.05% cross-linking agent to (2) and cross-...

Embodiment 2

[0050] (1) Obtain a 3D printed sacrificial template by photolithography. Use liquid photosensitive resin as 3D printing material. First, a 3D hollow cube was designed on the SolidWorks 2019 software, and 49 cone structures with a taper of 1 / 2 were set inside. Import it into the printing software CHITUBOX as an STL format, and set the printing parameters. Finally, import the program into the 3D printer for printing.

[0051] (2) Dissolve polyvinyl alcohol in ultrapure water, prepare a polyvinyl alcohol suspension with a mass concentration of 5%-15%, and raise the temperature to 95°C. Add 1%-5% sodium alginate to it and cool to room temperature.

[0052] (3) Add 0.1%-0.5% foaming agent to (2), stir vigorously at 1500rmp for foaming, then add 0.25%-5% HCl (1mol / l).

[0053] (4) Add 0.025%-0.05% cross-linking agent to (2) and cross-link at 1000rmp for half an hour, and pour the cross-linked solution into the mold prepared in (1) and place it at 70° C oven for 4 hours to mak...

Embodiment 3

[0056] (1) Obtain a 3D printed sacrificial template by photolithography. Use liquid photosensitive resin as 3D printing material. First, a 3D hollow cube was designed on the SolidWorks 2019 software, and 49 cone structures with a taper of 2 / 3 were set inside. Import it into the printing software CHITUBOX as an STL format, and set the printing parameters. Finally, import the program into the 3D printer for printing.

[0057] (2) Dissolve polyvinyl alcohol in ultrapure water, prepare a polyvinyl alcohol suspension with a mass concentration of 5%-15%, and raise the temperature to 95°C. Add 1%-5% sodium alginate to it and cool to room temperature.

[0058] (3) Add 0.1%-0.5% foaming agent to (2), stir vigorously at 1500rmp for foaming, then add 0.25%-5% HCl (1mol / l).

[0059] (4) Add 0.025%-0.05% cross-linking agent to (2) and cross-link at 1000rmp for half an hour, and pour the cross-linked solution into the mold prepared in (1) and place it at 70° C oven for 4 hours to mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com