Low-carbon low-alloy steel superplastic material and preparation method thereof

A technology of low-alloy steel and superplasticity, which is applied in the field of superplastic material preparation, can solve problems such as complex preparation process, achieve simple implementation process, improve production and manufacturing efficiency, and realize the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method of low-carbon low-alloy steel superplastic material provided by the invention, preparation method comprises the following steps:

[0043] Step 1, smelting the low-carbon and low-alloy steel. During the smelting process, mold casting is used to produce ingots or continuous casting is used to produce continuous casting slabs. In the smelting process, converters, electric furnaces and induction furnaces can be used for smelting.

[0044] Step 2: rolling the cast ingot or continuous casting billet into shape, and obtaining a billet with lamellar or lath-like structure after cooling, and obtaining a ferrite-austenite dual-phase structure after the billet is annealed.

[0045] In a specific embodiment of the present invention, the rolling forming includes hot rolling or cold rolling, and the rolling deformation is more than 30%; if the rolling deformation is too small, the structure formed during the high-temperature tensile deformation process wi...

Embodiment 1

[0053] Preparation of 0.1C5Mn2Al Steel Superplastic Material

[0054] The 0.1C5Mn2Al steel means that according to the mass percentage, the C element content is 0.1%, the Mn element content is 5%, and the Al element content is 2%.

[0055] A method for preparing a low-carbon low-alloy steel superplastic material provided in this embodiment comprises the following steps:

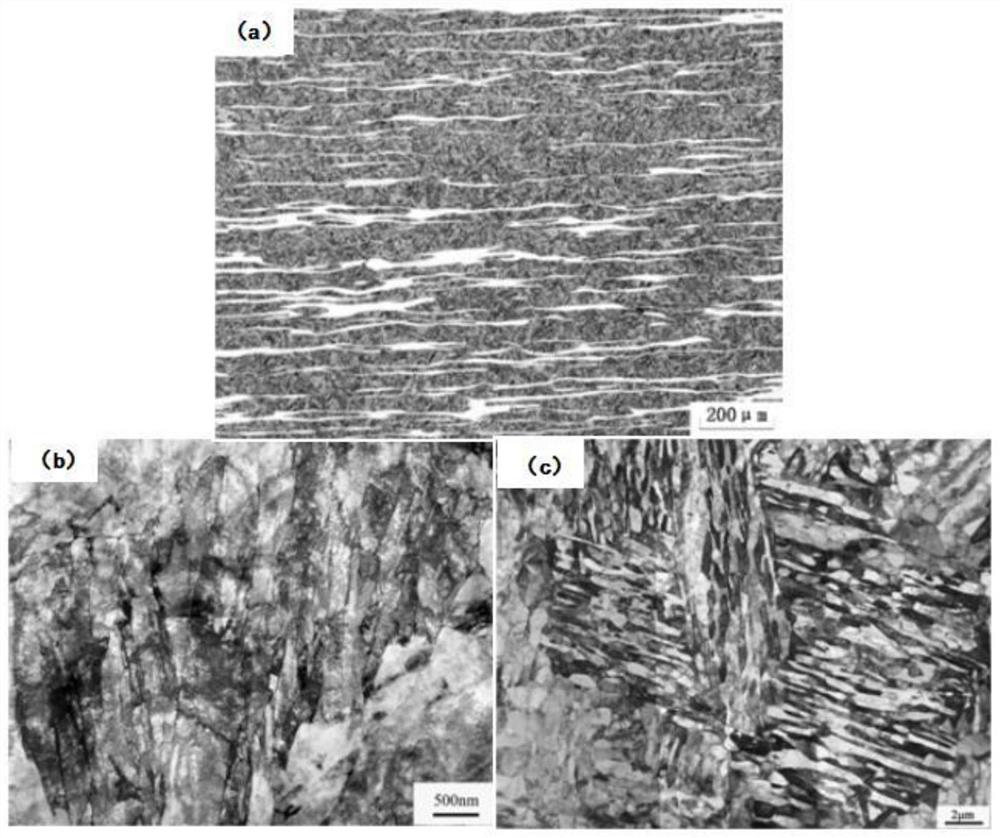

[0056] First, smelt, cast and forge a billet with a thickness of 30mm and a composition of 0.1C5Mn2Al using a 50kg vacuum induction furnace in the raw material laboratory, and then heat it through 4 passes (30-24-20-15-12mm) after holding it at 1200°C for 2 hours. After rolling to a thickness of 12mm, air cool to room temperature to form ferrite and martensite structures such as figure 2 Shown in (a). The amount of deformation after rolling was 60%.

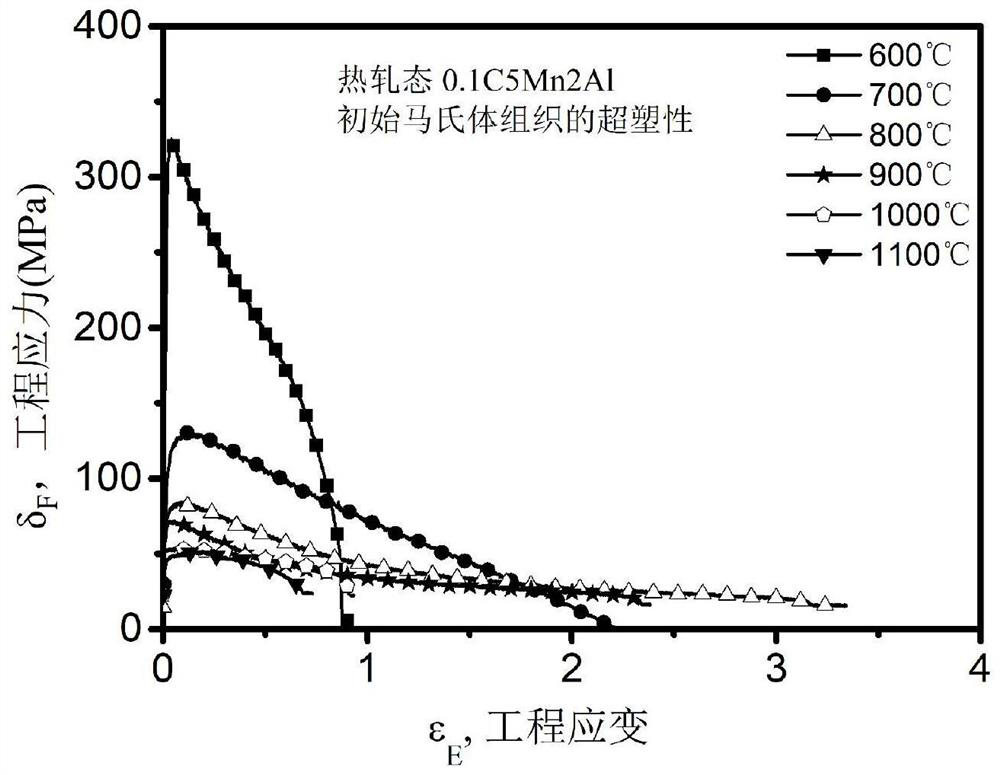

[0057] The specimens were then machined to standard tensile specimen dimensions, which were heated to different temperatures for 10 -3 / s tensile rate for ...

Embodiment 2

[0060] Preparation of 0.05C5Mn2Al Steel Superplastic Material

[0061] 0.05C5Mn2Al steel means that according to mass percentage, the C element content is 0.05%, the Mn element content is 5%, and the Al element content is 2%.

[0062] A method for preparing a low-carbon low-alloy steel superplastic material provided in this embodiment comprises the following steps:

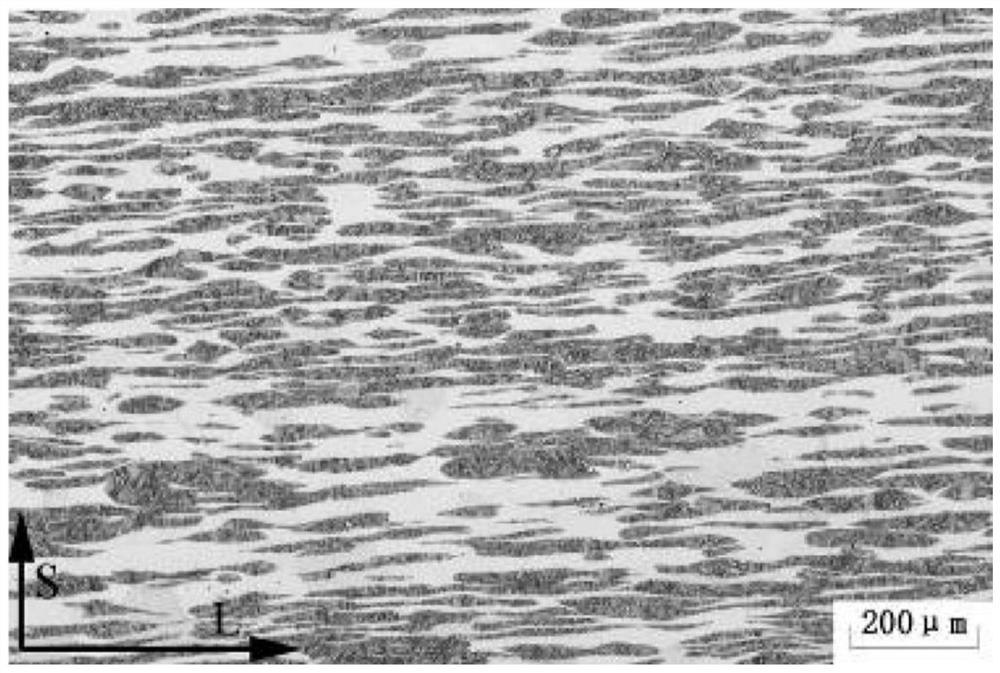

[0063] First, smelt, cast and forge a billet with a thickness of 30mm and a composition of 0.05C5Mn2Al using a 50kg vacuum induction furnace in the raw material laboratory, and then heat it through 4 passes (30-24-20-15-12mm) after holding it at 1200°C for 2 hours. Air-cool to room temperature after rolling to 12 mm; deformation after rolling is 60%. Lamellar ferrite and martensite two-phase alternate structure formed after hot rolling, such as image 3 shown. The specimens were then machined to standard tensile specimen dimensions, which were heated to different temperatures for 10 -2 / s tensile rate for supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com