Preparation method of ultra-light multi-feature skin-free skeleton type composite material shell

A composite material and skeleton-type technology, which is applied in the field of ultra-lightweight multi-feature skinless skeleton composite shell preparation, can solve the problems of poor dimensional accuracy of ribs, difficulty in connecting skeleton ribs and end frames, and rib defects, etc. problems, to achieve the effect of ensuring rigidity and stability, uniform and effective connection, and meeting the requirements of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

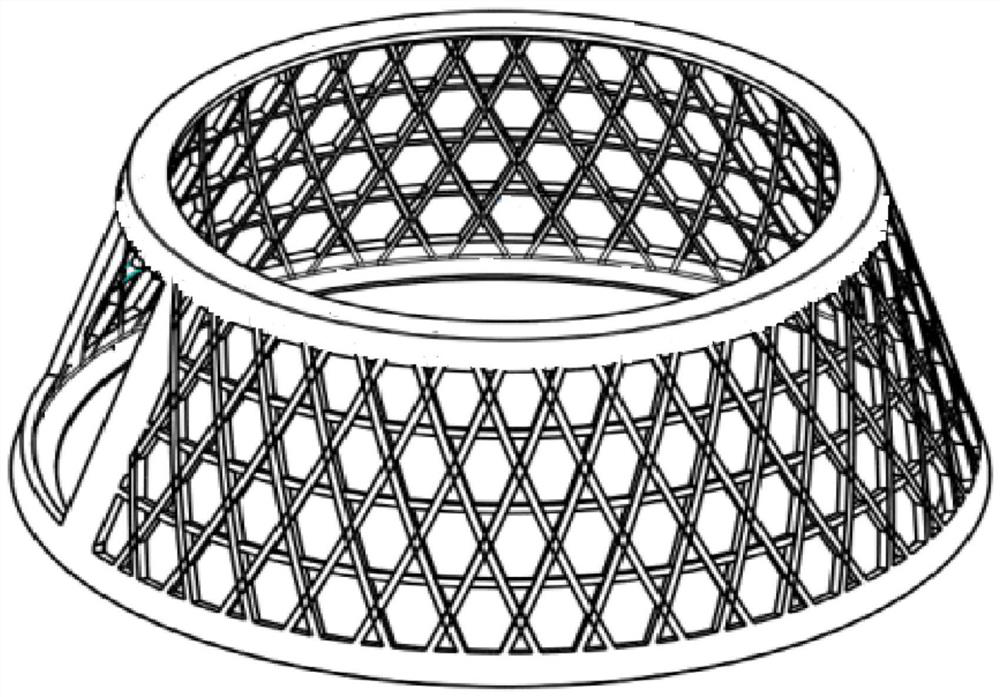

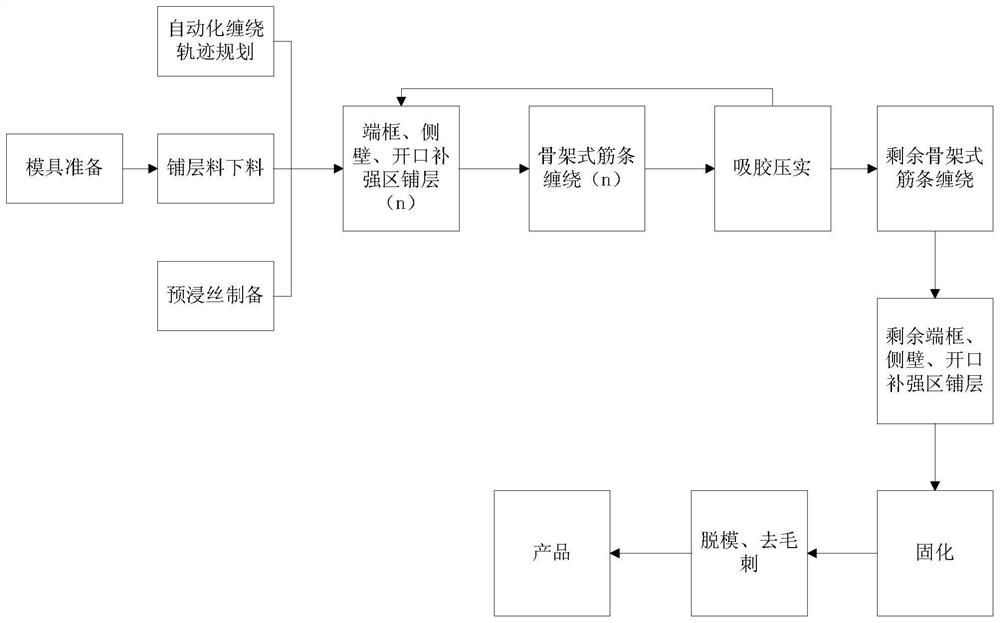

[0035] The embodiment of the present invention provides a method for preparing an ultra-light multi-featured skinless skeleton composite shell, the shell is as follows figure 1 As shown, it includes skeleton ribs, upper and lower side walls, up and down inversion end frames, large openings and opening reinforcement areas, and its side walls or end frames can be of variable thickness structure. The preparation method includes the following steps:

[0036] (1) Install the lower head guide and positioning device, the main body forming mold, and the upper end head guide and positioning device on the main shaft in sequence, fix the main shaft on the CNC winding machine, and move the positioning device to be separated from the main body forming mold by at least 150mm.

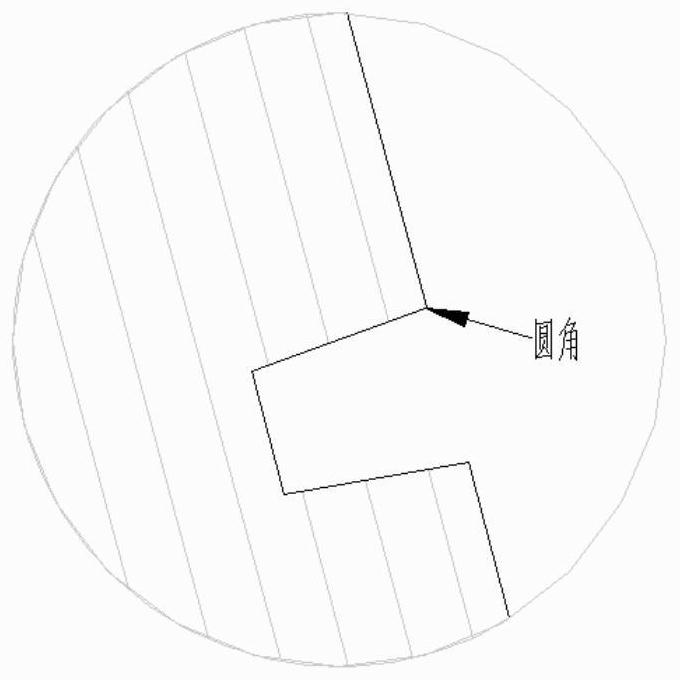

[0037] (2) According to the three-dimensional model of the product, the trajectory planning of the automatic winding line is carried out. This step is performed by the existing method. According to the three-dimension...

Embodiment 1

[0056] Product overview: The size of the rib is 6mm*9mm, and the thickness of the end frame, side wall, and opening reinforcement area is 9mm. It is prepared by using hot-melt prepreg with a single layer thickness of 0.15mm.

[0057] The implementation steps are as follows:

[0058] (1) Install the lower head guide and positioning device, the main body forming mold (core mold + split male module), and the upper end head guide and positioning device on the main shaft in sequence, fix the mold on the CNC winding machine, and move the positioning device to the main body Forming mold phase separation at least 150mm.

[0059] (2) According to the three-dimensional model of the product, the trajectory planning of the automatic winding line is carried out.

[0060] (3) Using hot-melt prepreg, according to the three-dimensional model of the product, choose hot-melt prepreg with a width of 6mm, calculate the number of prepreg used for the skeleton ribs as 60 pieces, and use prepreg c...

Embodiment 2

[0070] Product overview: The rib size is 9mm*12mm, the thickness of the upper frame, side wall, and opening reinforcement area is 12mm, and the thickness of the lower frame gradually changes from 12mm to 6mm. It is prepared by using hot-melt prepreg with a single layer thickness of 0.15mm.

[0071] The implementation steps are as follows:

[0072] (1) Install the lower head guide and positioning device, the main body forming mold, and the upper end head guide and positioning device on the main shaft in sequence, fix the mold on the CNC winding machine, and move the positioning device to be separated from the main forming mold by at least 150mm.

[0073] (2) According to the three-dimensional model of the product, the trajectory planning of the automatic winding line is carried out.

[0074] (3) Using hot-melt prepreg, according to the three-dimensional model of the product, choose hot-melt prepreg with a width of 6mm, calculate the number of prepreg used for the skeleton ribs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com