Cellular board with sealing edges and preparation method thereof

A honeycomb panel and honeycomb technology, applied in the field of honeycomb panels with edge sealing and their preparation, can solve the problems of low reuse rate, heavy weight, inconvenient transportation, etc., and achieve high flexibility, convenient disassembly, and simple efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

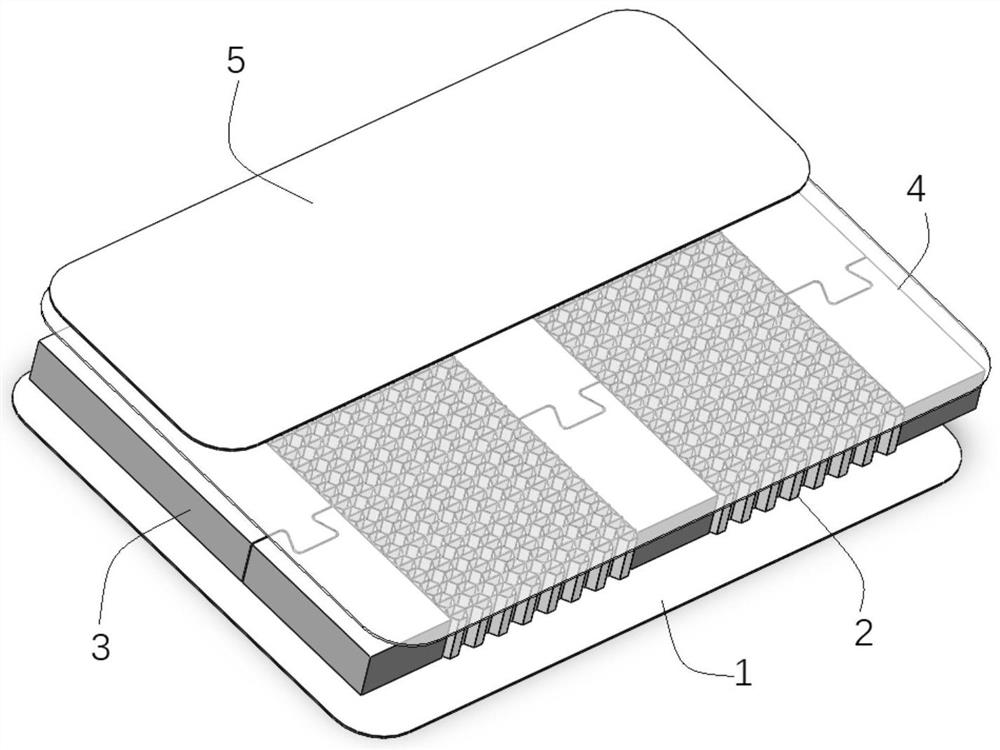

[0031] Such as figure 1 The width of the lower surface 1 is the width of two finished products. The material is a unidirectional tape made of pre-impregnated continuous fibers, and then a thermoplastic composite material is designed through multi-directional layup. Because the lower surface 1 is not used as a functional surface, There is no coating layer and PET protective film, the thickness is thinner than the upper surface 5, and the peeling is better than the upper part. Place the honeycomb core 2 on the lower surface 1, and two honeycomb cores 2 can be placed into the machine at the same time. The width can be customized according to requirements. , the material is polypropylene, and the tubular shape is hexagonal honeycomb or circular honeycomb. In order to improve the compression resistance and impact resistance, the density of the larger honeycomb core can be selected. What is used in this embodiment is 100-110Kg / m 3 honeycomb core with the highest density; in the midd...

Embodiment 2

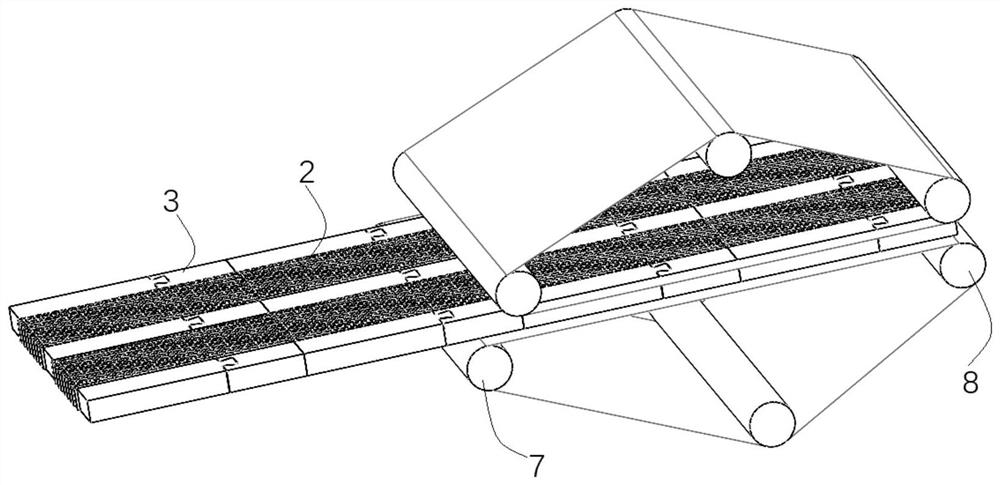

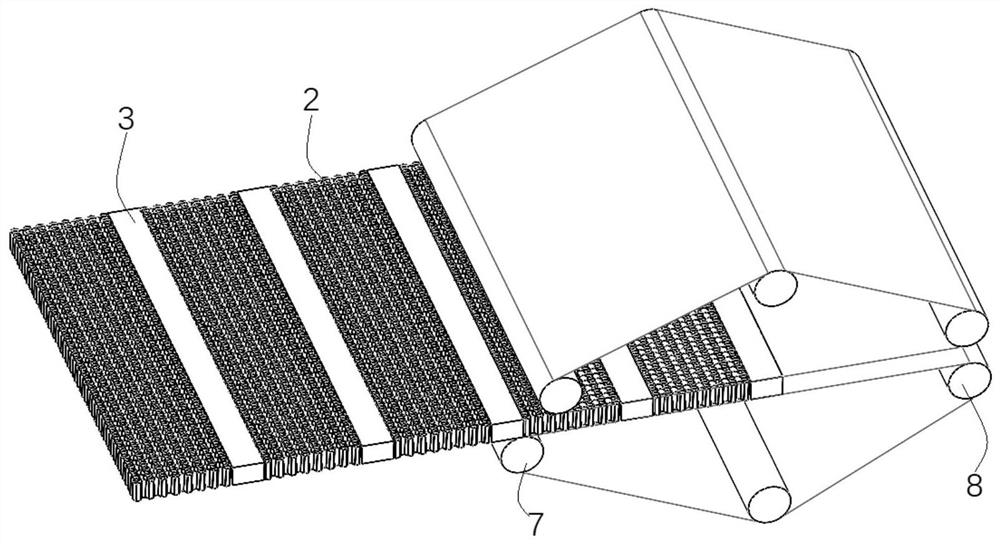

[0037] Such as image 3 The structure is the same as in Example 1, the difference is that the feeding method is different.

[0038] The specific steps of this embodiment are as follows:

[0039] S1: The upper and lower surfaces are made of continuous fiber-reinforced thermoplastic materials. The upper surface 5 includes 4 layers of continuous fiber-reinforced thermoplastic materials, and the surface has a layer of pp coated surface and a corona-treated PET protective film. The lower surface 1 is Two layers of continuous fiber-reinforced thermoplastic material, with a layer of low-temperature adhesive film 4 between the upper surface and the honeycomb core, and a honeycomb panel made by compounding the upper and lower surfaces with the honeycomb core 2 through thermal compounding process, the density of the selected honeycomb core 2 is 108kg / m 3 .

[0040] S2: There is a layer of low-temperature adhesive film 4 between the upper surface 5 and the honeycomb core 2. Because th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com