Device for effectively reducing volatilization of ammonium hydroxide in SC1 and operation method

A technology of ammonia water and water-cooled tubes, which is applied in the directions of packaging, transportation and packaging, tankers, etc., to achieve the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

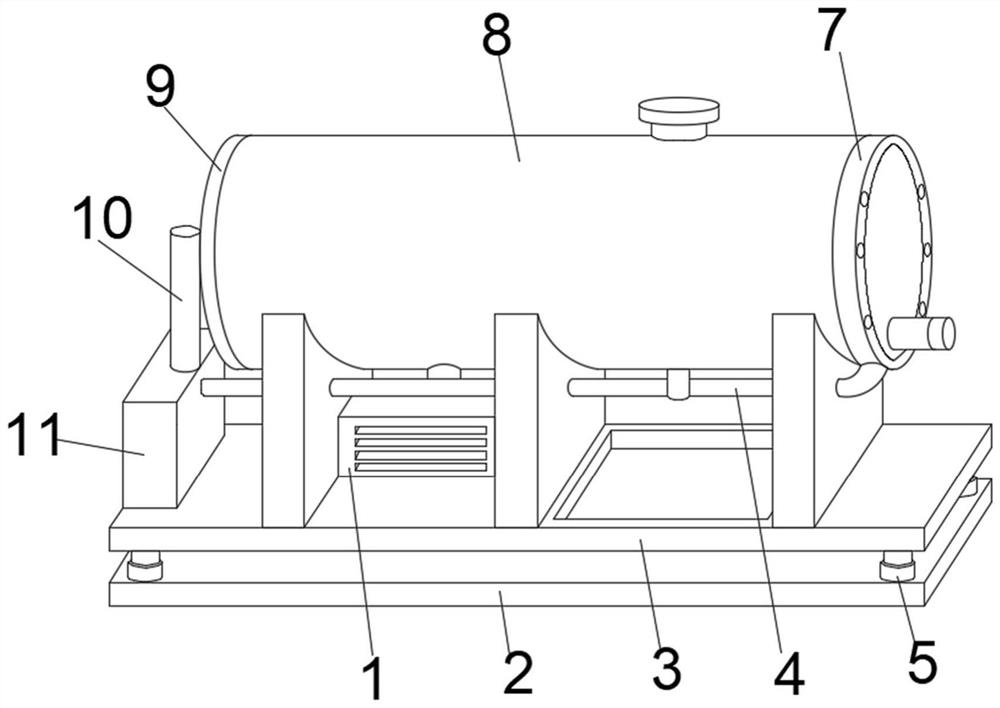

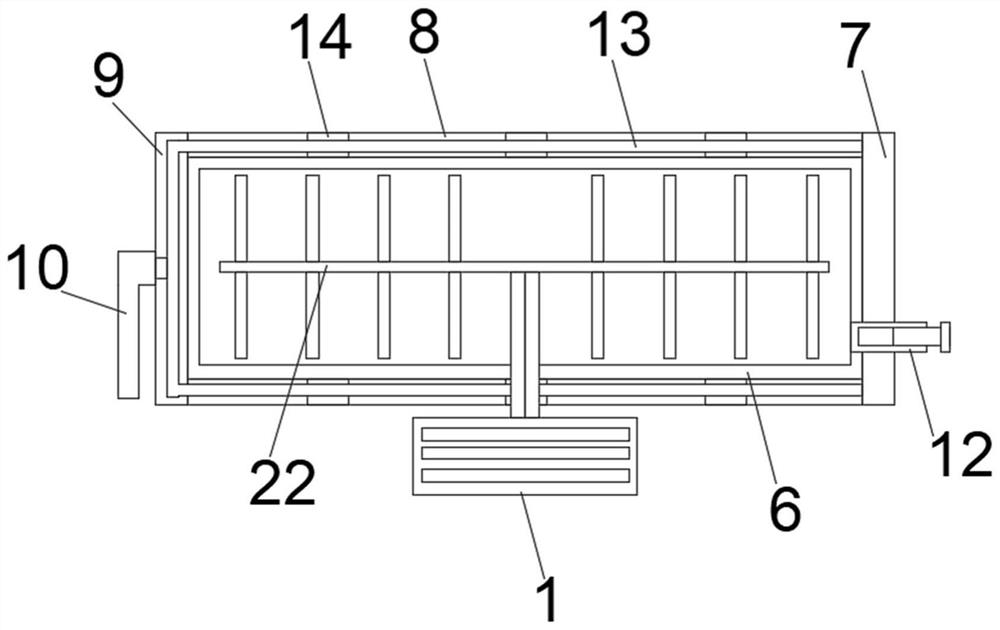

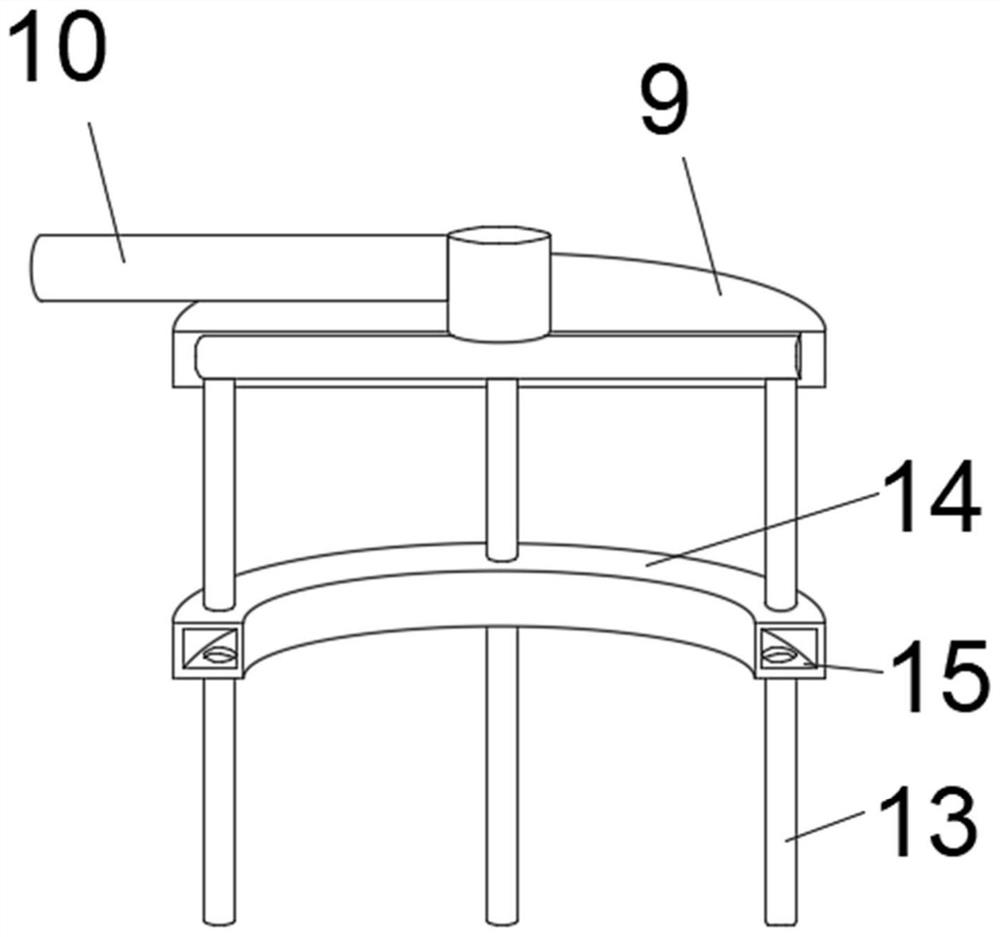

[0038] A second chuck 9 is fixedly installed on the outer surface of one end of the outer cylinder body 8, and a first chuck 7 is fixedly installed on the outer surface of the other end of the outer cylinder body 8. Utilizing the setting of the first chuck 7 and the second chuck 9, The two ends of the outer cylinder 8 are sealed and fixed, and at the same time, the installation operation between the outer cylinder 8 and the inner cylinder 6 is convenient. The outer cylinder 8 and the inner cylinder 6 are used to form a double-layer heat insulation structure, which can effectively reduce the Ammonia volatilization rate.

[0039] One side of the second chuck 9 is provided with a connecting pipe 10, and the lower end of the connecting pipe 10 is equipped with a circulating water tank 11, and one end of the water-cooled pipe 13 is connected with the connecting pipe 10 through a branch pipe, and the circulating water tank 11 can be used. The pipe 10 cooperates with the branch pipe ...

Embodiment 2

[0043] A compressor 1 is installed at the lower end of the cooling pipe 22 , and the compressor 1 is used to inject refrigerant into the cooling pipe 22 , so as to cool the SC1 liquid in the inner cylinder 6 through the cooling pipe 22 .

[0044] One end of the hydraulic rod 5 is provided with a second roller 17, the hydraulic rod 5 and the balance plate 3 are flexibly connected by the second roller 17, the other end of the hydraulic rod 5 is provided with a first roller 16, the hydraulic rod 5 and the fixed The bottom plates 2 are movably connected by the first roller 16, and the use angle of the hydraulic rod 5 can be flexibly adjusted by using the setting of the first roller 16 and the second roller 17, so that the fixed bottom plate 2 and the balance plate 3 can be Balance adjustment operation.

[0045] There is a liquid discharge groove on the suction pipe 21, and a docking chuck 18 is fixedly installed on the outer surface of the discharge pipe 12. By pulling the suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com