Mulberry-leaf solid instant beverage, intermediate and preparation method of mulberry-leaf solid instant beverage

An intermediate and mulberry leaf technology, which is applied in the field of solid instant beverage preparation, can solve problems such as limited use scenarios, and achieve the effects of good taste, convenient storage and transportation, and uniform soup color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

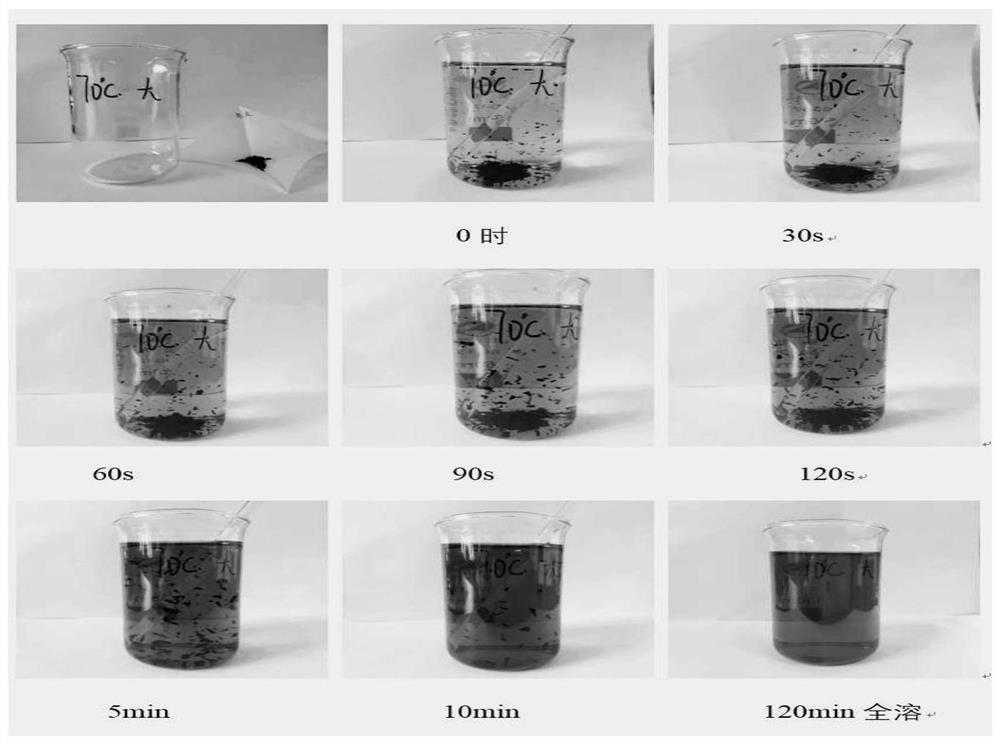

[0044] The preparation of embodiment 1 mulberry leaf extract

[0045] Take the mulberry leaves (including dried mulberry leaves and mulberry leaf tea obtained by various processing methods) of the same medicine and food as raw materials, and follow the steps below:

[0046] Dry mulberry leaves are mechanically crushed and passed through a 60-mesh sieve. 12 times of purified water was added, the extraction temperature was 70°C, the extraction time was 0.5h each time, and a total of 2 extractions were made. The extracts were combined and centrifuged at 5000r / min for 20 minutes to remove the coarse filter residue. The crude filtrate was filtered through a ceramic membrane (pore size: 50 nm) until the solution was clear. The filtered solution was concentrated under reduced pressure at 60°C, and the concentrated solution was dried at 60°C under reduced pressure, and the vacuum degree was -0.01Mpa. The dry material is crushed, screened and packaged.

Embodiment 2

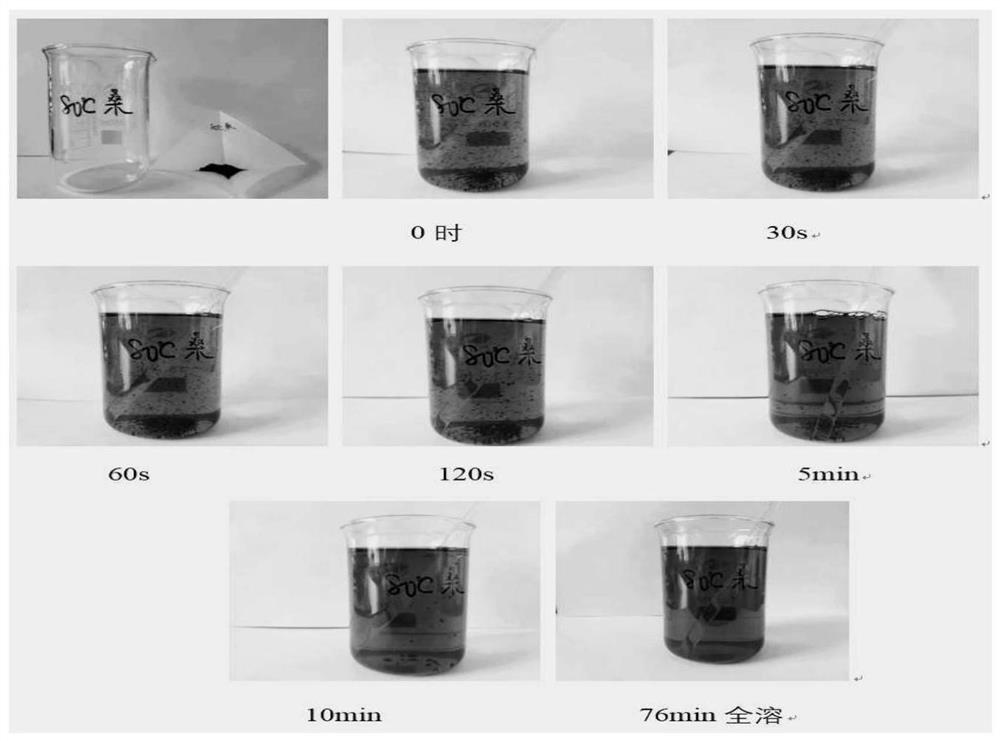

[0047] The preparation of embodiment 2 mulberry leaf extract

[0048] Take the mulberry leaves (including dried mulberry leaves and mulberry leaf tea obtained by various processing methods) of the same medicine and food as raw materials, and follow the steps below:

[0049] Dry mulberry leaves are mechanically crushed and passed through a 60-mesh sieve. Add 12 times of purified water, extract at an extraction temperature of 80°C, and extract for 0.5 hours each time, and extract twice in total. The extracts were combined and centrifuged at 5000r / min for 20 minutes to remove the coarse filter residue. The crude filtrate was filtered through a ceramic membrane (pore size: 50 nm) until the solution was clear. The filtered solution was concentrated under reduced pressure at 60°C, and the concentrated solution was dried at 60°C under reduced pressure, and the vacuum degree was -0.01Mpa. The dry material is crushed, screened and packaged.

Embodiment 3

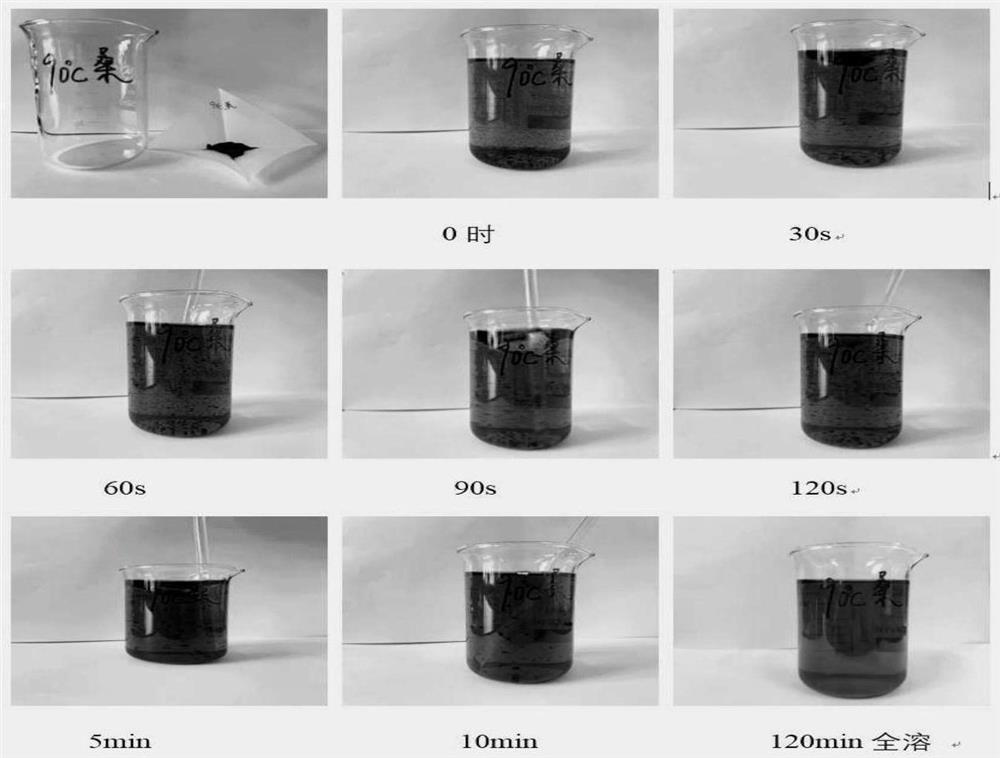

[0050] The preparation of embodiment 3 mulberry leaf extract

[0051] Take the mulberry leaves (including dried mulberry leaves and mulberry leaf tea obtained by various processing methods) of the same medicine and food as raw materials, and follow the steps below:

[0052] Dry mulberry leaves are mechanically crushed and passed through a 60-mesh sieve. Add 12 times of purified water, extract at an extraction temperature of 90°C, and extract for 0.5 hours each time, and extract twice in total. The extracts were combined and centrifuged at 5000r / min for 20 minutes to remove the coarse filter residue. The crude filtrate was filtered through a ceramic membrane (pore size: 50 nm) until the solution was clear. The filtered solution was concentrated under reduced pressure at 60°C, and the concentrated solution was dried at 60°C under reduced pressure, and the vacuum degree was -0.01Mpa. The dry material is crushed, screened and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com