Treatment method for reducing content of starch, protein and saccharides in rubber wood

A processing method and protein technology, applied in wood processing, wood processing details, impregnating wood, etc., can solve the problems of lack of mold growth and limited anti-mold effect, and achieve the effects of enhanced aesthetics, environmentally friendly processing methods, and enhanced aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

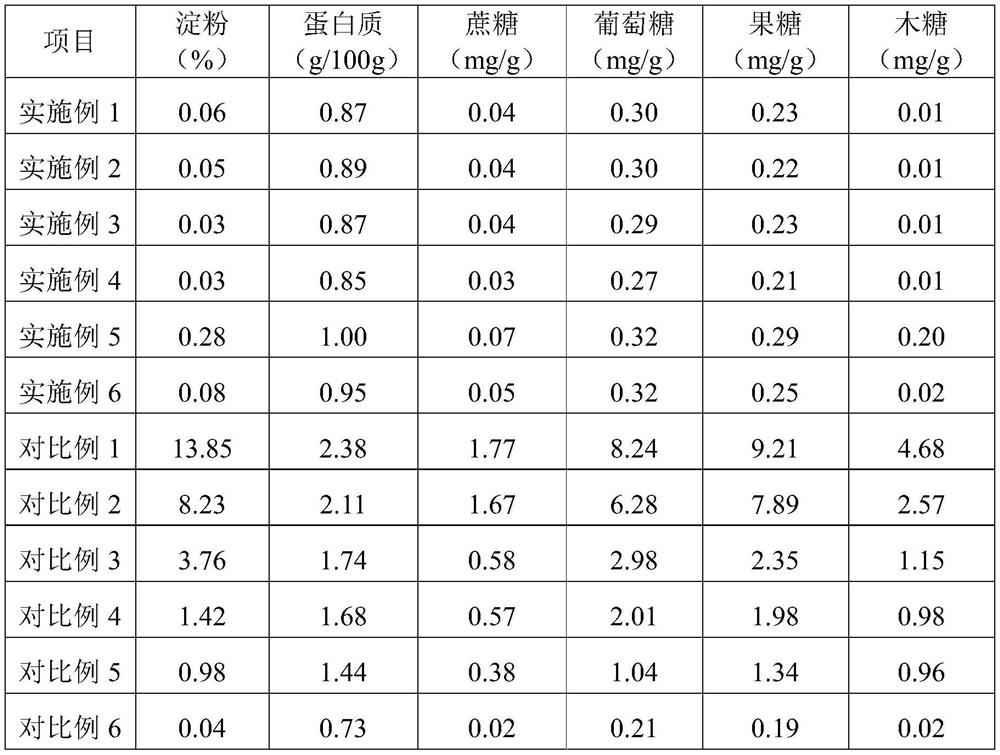

Embodiment 1

[0030] A treatment method for reducing starch, protein and sugar content in rubber wood, comprising the steps of:

[0031] (1) Acidification treatment: Add 120kg of oxalic acid solution with a mass concentration of 0.5% to the rubber wood with a thickness of 1.5cm, immerse the rubber wood, adopt a temperature of 20°C, an ultrasonic frequency of 25KHz, and an ultrasonic power of 300W, and perform ultrasonic treatment for 30min. Acidified wood;

[0032] (2) Neutralization treatment: according to the mass ratio of 3:4, 160kg of alkaline nano-sodium silicate solution with a mass concentration of 10% was added to the acidified wood, the pH value was 9, the particle size was 10nm, and the modulus was 2.5. Including ultrasonic treatment in the pre-ultrasonic period and ultrasonic oscillation period, ultrasonic pre-ultrasound: ultrasonic power is 500W, ultrasonic time is 30min; ultrasonic oscillation period: after ultrasonic pre-treatment, adjust the ultrasonic power to 300W, the osci...

Embodiment 2

[0036] A treatment method for reducing starch, protein and sugar content in rubber wood, comprising the steps of:

[0037] (1) Acidification treatment: Add 120 kg of oxalic acid solution with a mass concentration of 5.0% to the rubber wood with a thickness of 8.5 cm, immerse the rubber wood, adopt a temperature of 80 ° C, an ultrasonic frequency of 80 KHz, and an ultrasonic power of 5400 W, and perform ultrasonic treatment for 240 min. Acidified wood;

[0038] (2) Neutralization treatment: according to the mass ratio of 4:5, 150kg of alkaline nano-sodium silicate solution with a mass concentration of 30% was added to the acidified wood, the pH value was 11, the particle size was 30nm, and the modulus was 1.0. Including ultrasonic treatment in the pre-ultrasound and ultrasonic oscillation period, the ultrasonic pre-ultrasound: the ultrasonic power is 1500W, the ultrasonic time is 120min; the ultrasonic oscillation period: after the ultrasonic pre-treatment, the ultrasonic power...

Embodiment 3

[0042] A treatment method for reducing starch, protein and sugar content in rubber wood, comprising the steps of:

[0043] (1) Acidification treatment: Add 100 kg of acetic acid solution with a mass concentration of 3% to the rubber wood with a thickness of 3.5 cm, immerse the rubber wood, adopt a temperature of 40 ° C, an ultrasonic frequency of 45 KHz, an ultrasonic power of 1000 W, and an ultrasonic time of 60 min. Perform ultrasonic treatment to obtain acidified wood;

[0044] (2) Neutralization treatment: according to the mass ratio of 2:3, 150kg of alkaline nano-sodium silicate solution with a mass concentration of 25% was added to the acidified wood, the pH value was 10, the particle size was 20nm, and the modulus was 1.8. Including ultrasonic treatment in pre-ultrasound and ultrasonic oscillation period, pre-ultrasound: ultrasonic power is 1000W, ultrasonic time is 60min; ultrasonic oscillation period: after ultrasonic pre-treatment, adjust ultrasonic power to 800W, os...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com