PHC product as well as PHC substrate and plastic part used by PHC product

A technology for plastic parts and products, which is applied to vehicle parts, transportation and packaging, spare tire layout, etc., can solve the problem of inconvenient operation of the four-claw nut scheme, achieve the effect of smooth assembly operation, high degree of uniformity, and increased connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

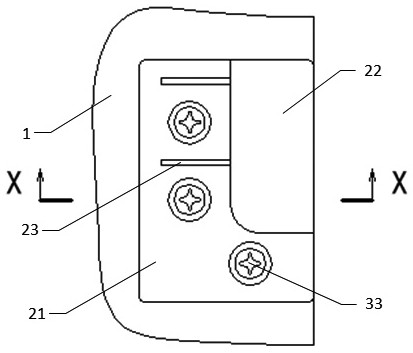

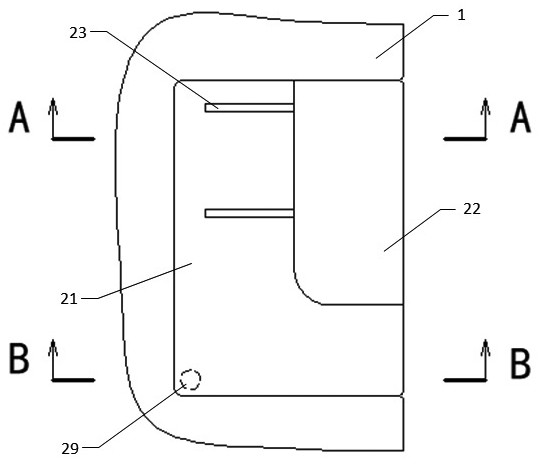

[0047] Such as image 3 As shown, in the scheme of this application, the structure of the rotating shaft seat seen from the back includes the bottom plate 21, the rib plate 23, and the rotating shaft limiting plate 22. The protrusion 29 under the bottom plate is invisible, and there are no screws to connect Shaft seat and PHC substrate 1.

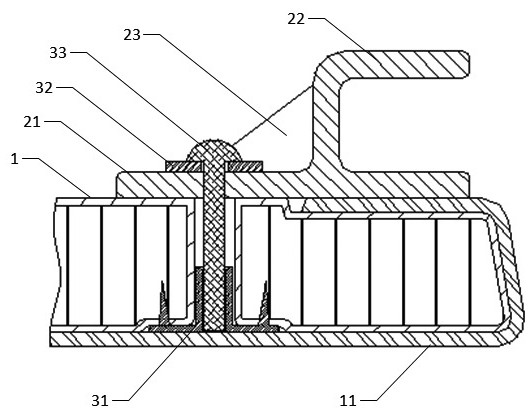

[0048] Such as Figure 4 As shown, it can be seen from the A-A sectional view of the connecting ribs that the shaft seat also includes side panels 25 and surface panels 24, as well as connecting ribs 26. The surface layer of the PHC substrate 1 is also provided with a fabric 11, and the area covered by the surface layer plate 24 of the rotating shaft seat may not be provided with a fabric. The advantage of doing this is to prevent the compressible fabric from affecting the matching between the rotating shaft seat and the PHC substrate.

[0049] Such as Figure 5As shown, it can be seen from the B-B sectional view cut at the protrusion 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com